Qashqai J11. Engine control system (HRA2DDT) - part 19

P2120 APP SENSOR

ECH-289

< DTC/CIRCUIT DIAGNOSIS >

[HRA2DDT]

C

D

E

F

G

H

I

J

K

L

M

A

ECH

N

P

O

4.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace error-detected parts.

4.

CHECK ACCELERATOR PEDAL POSITION SENSOR INPUT SIGNAL CIRCUIT

1.

Check the continuity between accelerator pedal position sensor harness connector and ECM harness

connector.

2.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair or replace error-detected parts.

5.

CHECK ACCELERATOR PEDAL POSITION SENSOR

ECH-289, "Component Inspection"

Is the inspection result normal?

YES

>> Perform intermittent incident. Refer to

GI-41, "Intermittent Incident"

.

NO

>> Replace accelerator pedal.

6.

CHECK ACCELERATOR PEDAL POSITION SENSOR POWER SUPPLY CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check the continuity between accelerator pedal position sensor harness connector and ECM harness

connector.

4.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> Perform the trouble diagnosis for power supply circuit.

NO

>> Repair or replace error-detected parts.

Component Inspection

INFOID:0000000010379170

1.

CHECK ACCELERATOR PEDAL POSITION SENSOR

1.

Reconnect all harness connectors disconnected.

2.

Turn ignition switch ON.

3.

Check the voltage ECM harness connector terminals under the following conditions.

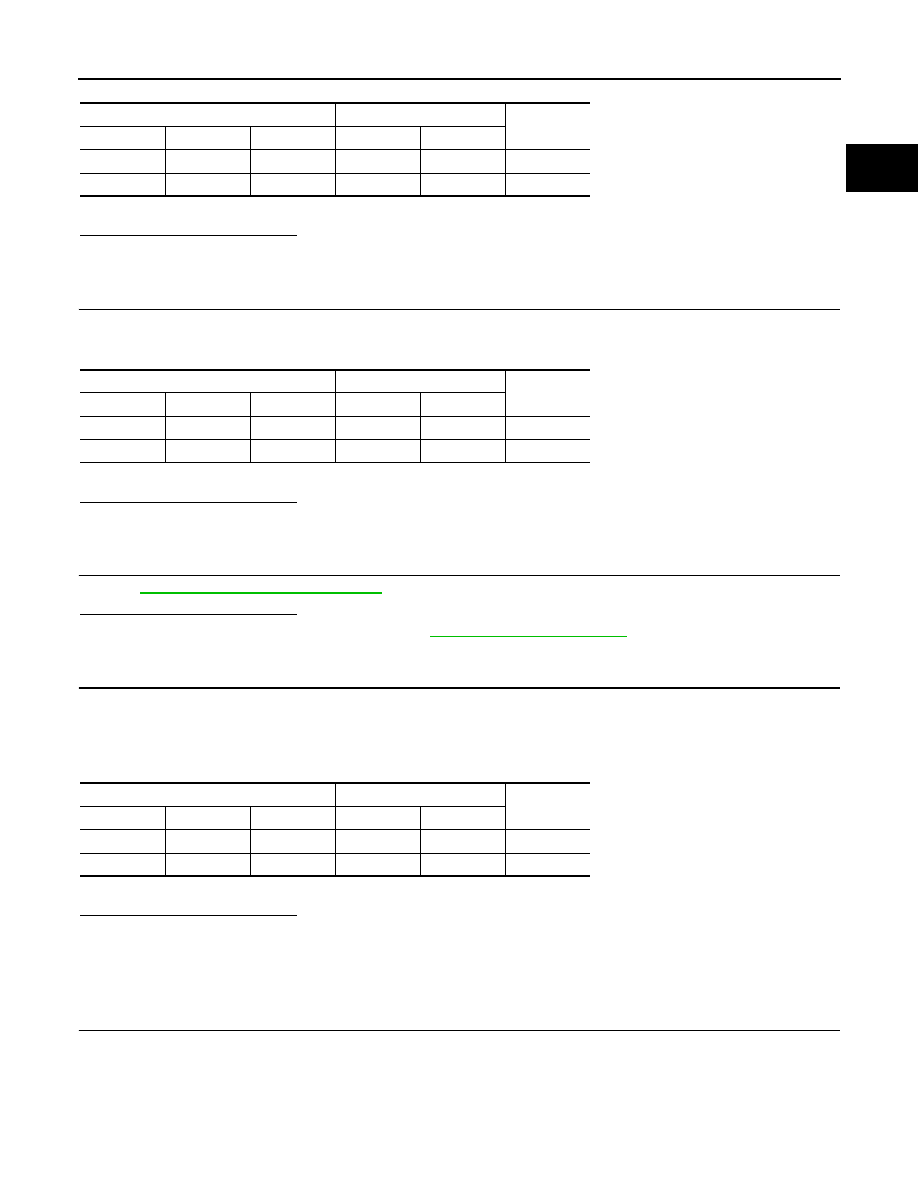

Accelerator pedal position sensor

ECM

Continuity

Sensor

Connector

Terminal

Connector

Terminal

1

E20

2

E9

30

Existed

2

E20

1

E9

21

Existed

Accelerator pedal position sensor

ECM

Continuity

Sensor

Connector

Terminal

Connector

Terminal

1

E20

3

E9

31

Existed

2

E20

6

E9

22

Existed

Accelerator pedal position sensor

ECM

Continuity

Sensor

Connector

Terminal

Connector

Terminal

1

E20

4

E9

27

Existed

2

E20

5

E9

23

Existed