Qashqai J11. Engine control system (HRA2DDT) - part 16

P062E ECM

ECH-241

< DTC/CIRCUIT DIAGNOSIS >

[HRA2DDT]

C

D

E

F

G

H

I

J

K

L

M

A

ECH

N

P

O

P062E ECM

DTC Logic

INFOID:0000000010500535

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

Turn ignition switch OFF and wait at least 12 minutes.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1.

Turn ignition switch ON and wait at least 10 second.

2.

Check DTC.

Is DTC detected?

YES

>> Proceed to

ECH-241, "Diagnosis Procedure"

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000010500536

1.

REPLACE ECM

1.

Replace ECM. Refer to

2.

>> INSPECTION END

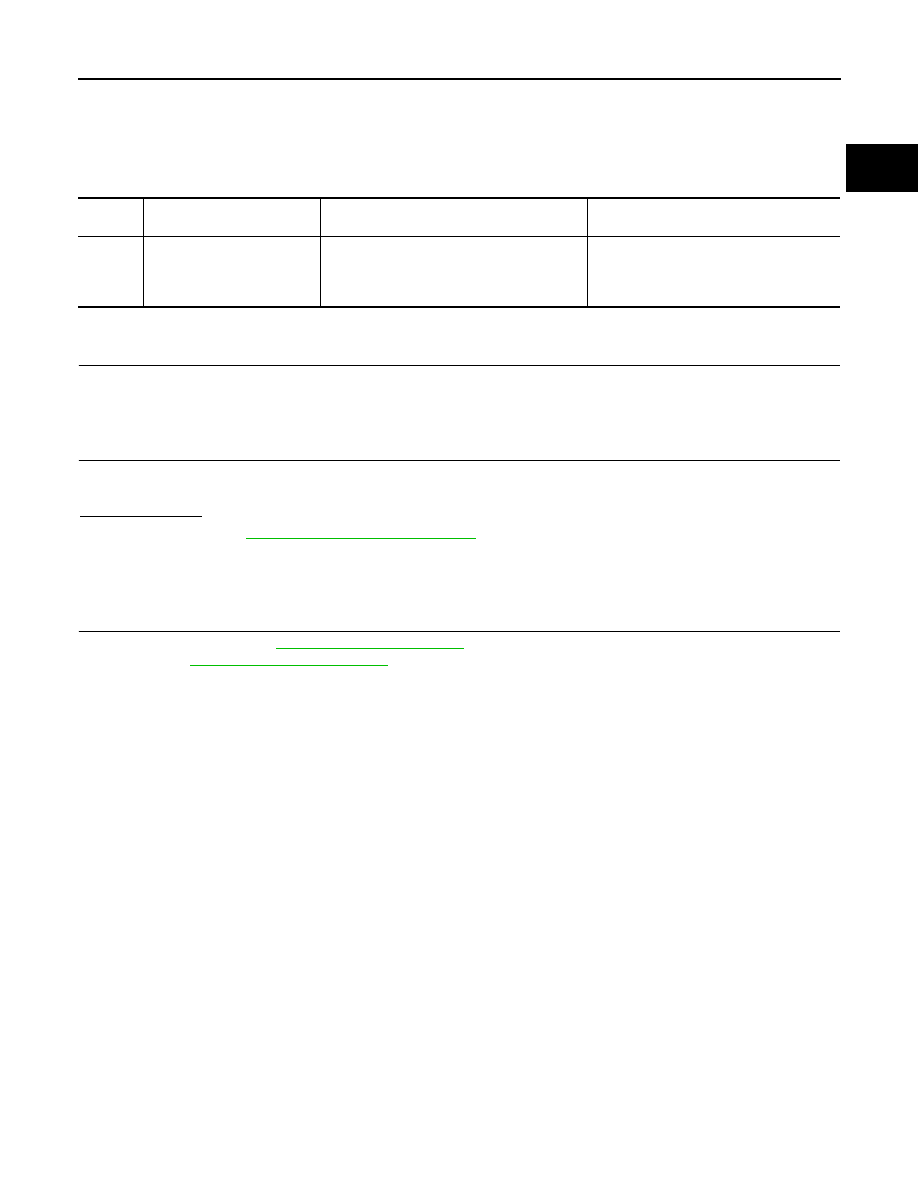

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P062E

FUEL INJECTOR DRIVER

B2

(Fuel injector driver circuit

performance bank 2)

ECM calculation function is malfunctioning.

ECM