Qashqai J11. Engine control system (HRA2DDT) - part 14

P0325 KNOCK SENSOR (KS)

ECH-209

< DTC/CIRCUIT DIAGNOSIS >

[HRA2DDT]

C

D

E

F

G

H

I

J

K

L

M

A

ECH

N

P

O

NO

>> GO TO 4.

4.

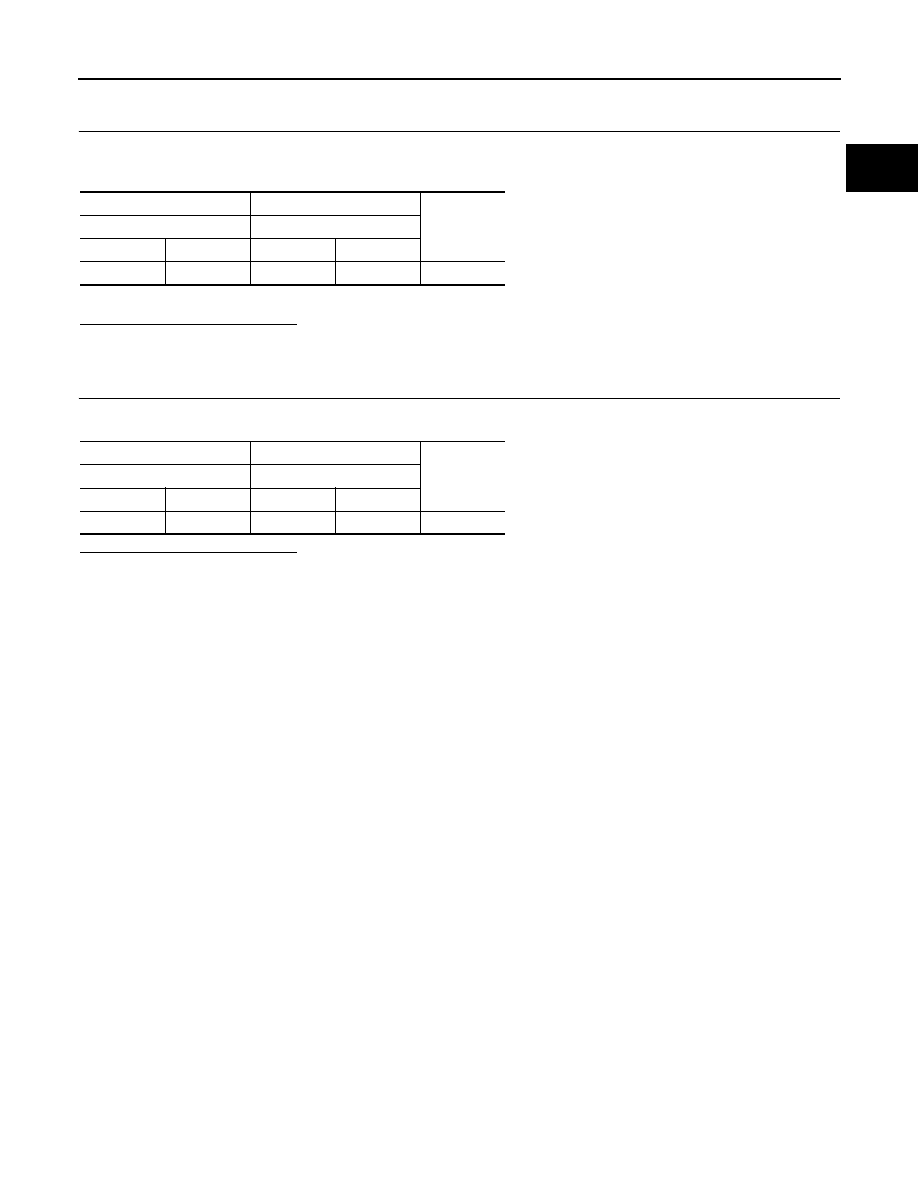

CHECK KNOCK SENSOR POWER SUPPLY CIRCUIT

1.

Disconnect knock sensor harness connector.

2.

Check the continuity between knock sensor harness connector and ECM harness connector.

3.

Also check harness for short to ground.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair or replace error-detected parts.

5.

CHECK KNOCK SENSOR GROUND CIRCUIT

Check the continuity between knock sensor harness connector and ECM harness connector.

Is the inspection result normal?

YES

>> Replace knock sensor.

NO

>> Repair or replace error-detected parts.

+

−

Continuity

Knock sensor

ECM

Connector

Terminal

Connector

Terminal

F33

2

F17

38

Existed

+

−

Continuity

Knock sensor

ECM

Connector

Terminal

Connector

Terminal

F33

1

F17

42

Existed