Qashqai J11. Engine control system (R9M) - part 14

EC9-210

< DTC/CIRCUIT DIAGNOSIS >

[R9M]

P0190 FRP SENSOR

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Perform trouble diagnosis for power supply circuit.

5.

CHECK FUEL RAIL PRESSURE SENSOR CIRCUIT FOR OPEN AND SHORT

1.

Turn ignition switch OFF.

2.

Check fuel rail pressure sensor circuit for open and short.

Is the inspection result normal?

YES

>> Replace fuel rail pressure sensor.

NO

>> Repair or replace error-detected parts.

+

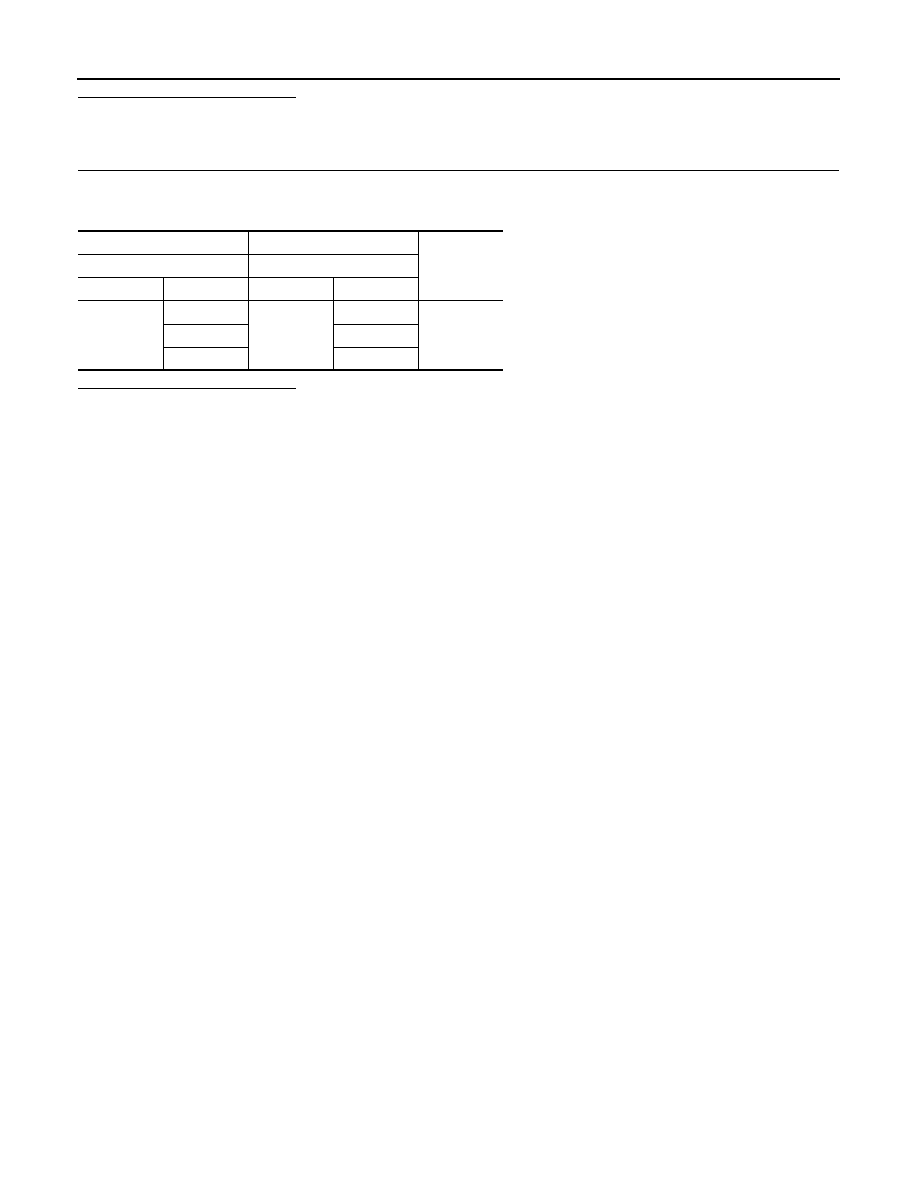

-

Continuity

ECM

Fuel rail pressure sensor

Connector

Terminal

Connector

Terminal

F82

73

F86

1

Existed

77

2

91

3