Nissan Qashqai J11. Manual - part 819

DLN-192

< SYMPTOM DIAGNOSIS >

[REAR FINAL DRIVE: R145]

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

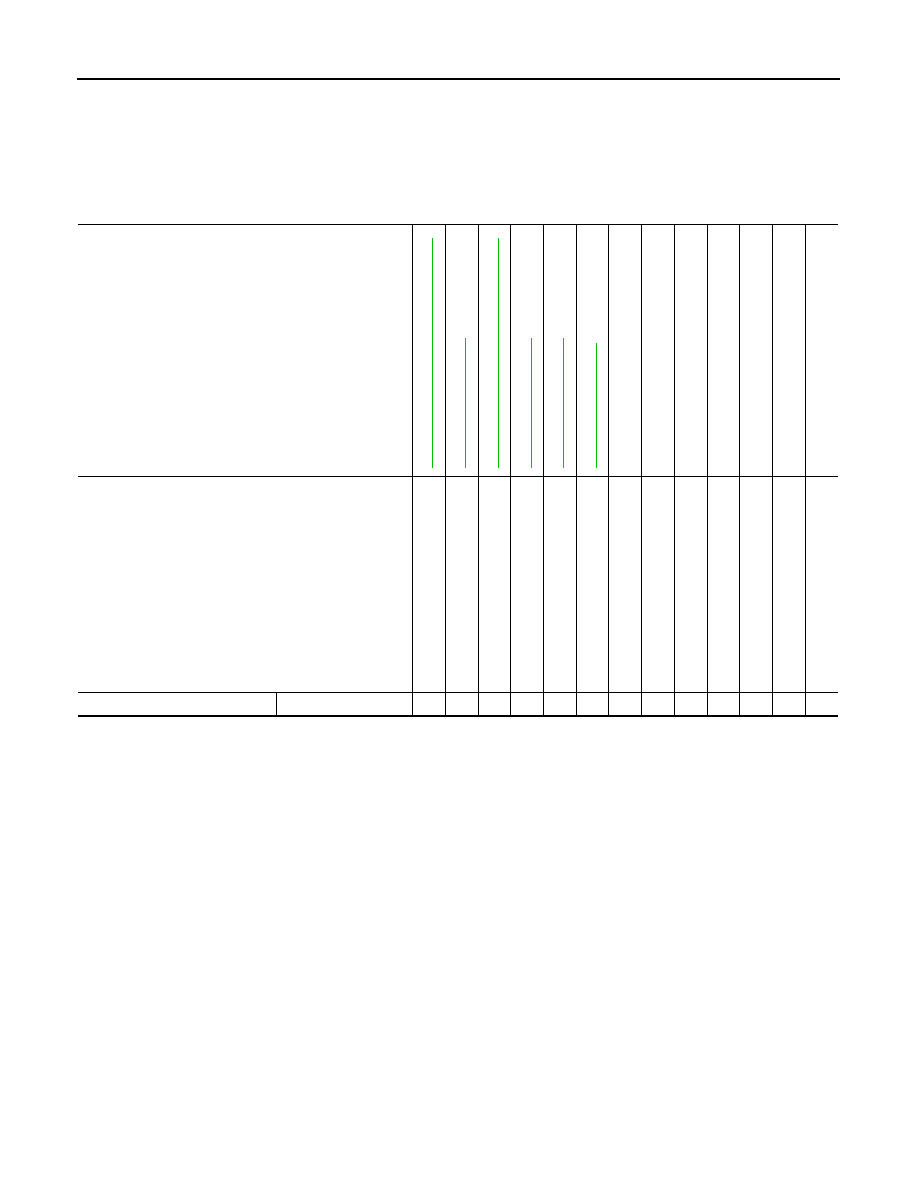

NVH Troubleshooting Chart

INFOID:0000000010288393

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×

: Applicable

Reference

NVH in DLN section

NVH in F

AX,

RAX, FSU and

R

S

U sections

NVH in WT section

NVH in WT section

NVH i

n

F

AX and RAX

secti

o

n

NVH in B

R

section

NVH in S

T

section

Possible cause and SUSPECTED PARTS

Gea

r to

ot

h ro

ug

h

Ge

ar co

nt

a

c

t im

pro

p

e

r

T

o

o

th su

rfac

es

wo

rn

Ba

ck

la

sh

in

co

rrec

t

Com

p

ani

on

fl

an

ge

ex

ce

ss

iv

e

run

o

u

t

Ge

ar oi

l im

pro

p

e

r

PROPELLER S

H

AFT

AXLE AND S

U

S

PENSION

TI

RE

ROAD WHEE

L

DRIVE SHAFT

BRAKE

STE

E

RING

Symptom

Noise

×

×

×

×

×

×

×

×

×

×

×

×

×