Nissan Qashqai J11. Manual - part 658

SERVICE DATA AND SPECIFICATIONS (SDS)

TM-207

< SERVICE DATA AND SPECIFICATIONS (SDS)

[6MT: RS6F52A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

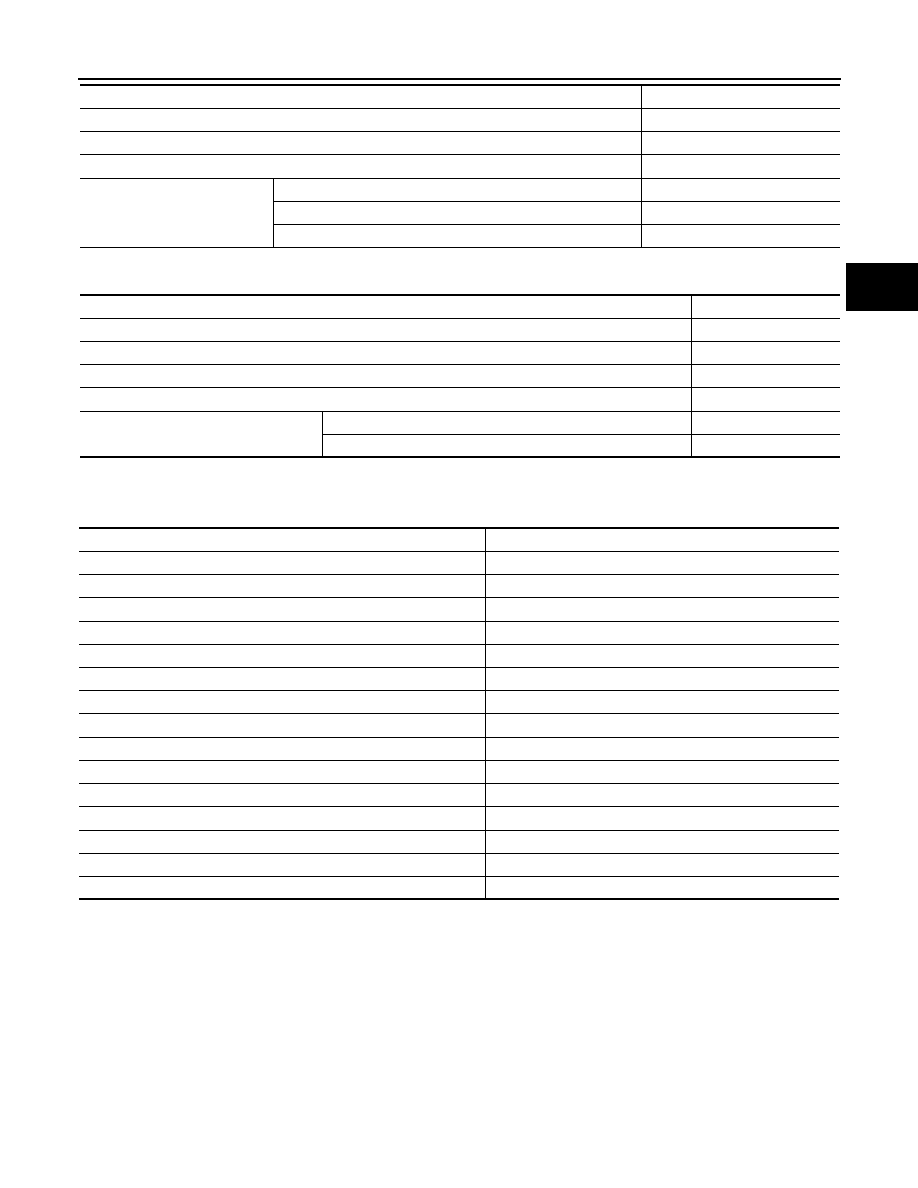

FINAL GEAR

End Play

INFOID:0000000010288544

Unit: mm (in)

Baulk Ring Clearance

INFOID:0000000010288545

Remarks

Reverse synchronizer

Installed

Double-cone synchronizer

3rd

Triple-cone synchronizer

1st and 2nd

Engine type

R9M

Transaxle model

RS6F52A

Axle type

4WD

Model code number

JA60A

Engine type

R9M

Transaxle model

RS6F52A

Axle type

4WD

Model code number

JA60A

Final gear ratio

4.266

Number of teeth

Final gear/Pinion

64/15

Side gear/Pinion mate gear

14/10

Items

Standard value

1st main gear

0.20 - 0.30 (0.0079 - 0.0118)

2nd main gear

0.06 - 0.16 (0.0024 - 0.0063)

6th main gear

0 - 0.1 (0 - 0.004)

3rd input gear

0.18 - 0.31 (0.0071 - 0.0122)

4th input gear

0.20 - 0.30 (0.0079 - 0.0118)

5th input gear

0.06 - 0.16 (0.0024 - 0.0063)

6th input gear

0.06 - 0.16 (0.0024 - 0.0063)

Reverse idler gear

0.04 - 0.10 (0.0016 - 0.0039)

6th input gear bushing

0 - 0.1 (0 - 0.004)

Input shaft

0 - 0.06 (0 - 0.0024)

Mainshaft

0 - 0.06 (0 - 0.0024)

Mainshaft C-ring

0 - 0.06 (0 - 0.0024)

Striking rod

0.05 - 0.152 (0.0020 - 0.0060)

Output gear bearing (For 4WD)

0 - 0.06 (0 - 0.0024)

Output gear assembly (For 4WD)

0 - 0.06 (0 - 0.0024)