Nissan Qashqai J11. Manual - part 652

INPUT SHAFT AND GEAR

TM-183

< UNIT DISASSEMBLY AND ASSEMBLY >

[6MT: RS6F52A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

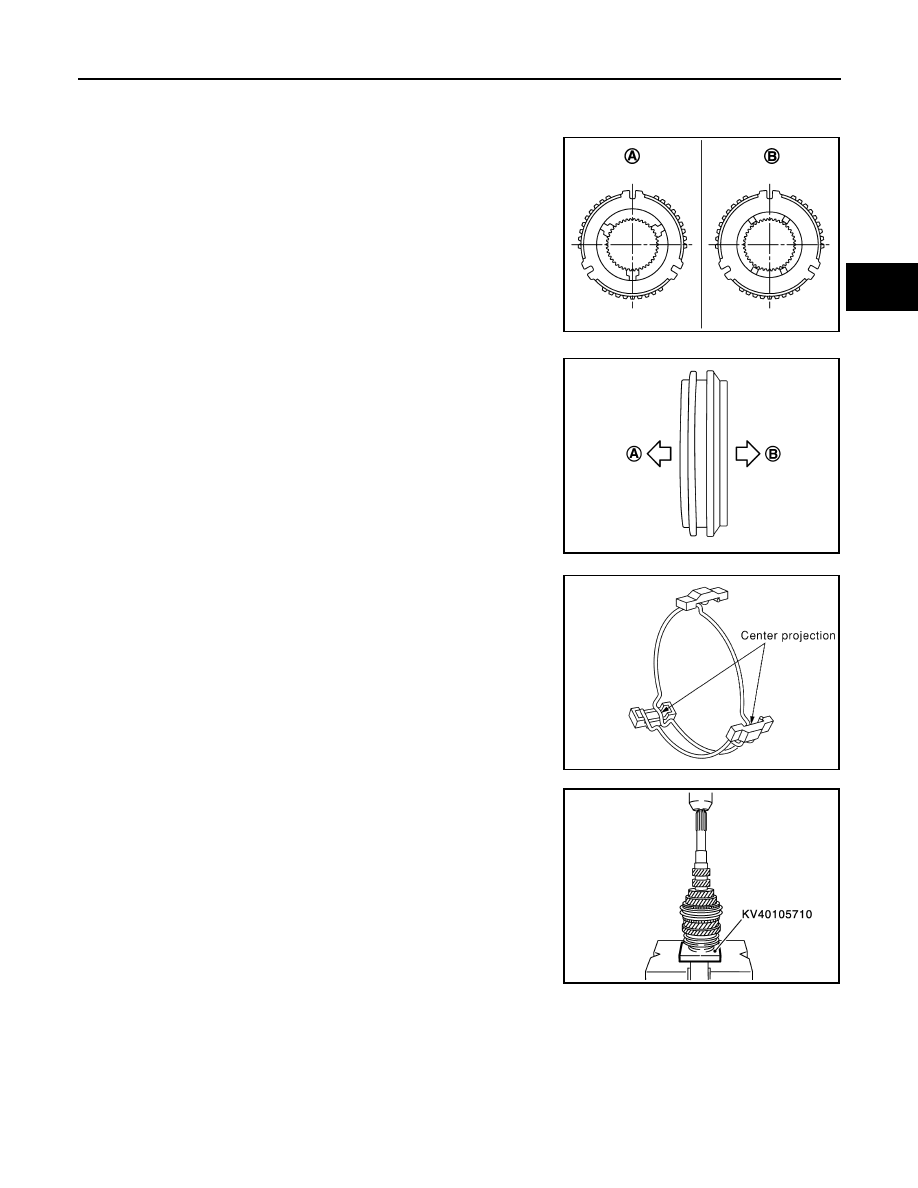

12. Install 5th-6th synchronizer hub, 5th-6th spread springs, and 5th-6th shifting inserts onto 5th-6th coupling

sleeve.

CAUTION:

• Be careful with orientation of 5th-6th synchronizer hub.

• Never reuse 5th-6th synchronizer hub and 5th-6th cou-

pling sleeve.

• Replace 5th-6th synchronizer hub and 5th-6th coupling

sleeve as a set.

• Be careful with orientation of 5th-6th coupling sleeve.

• Be sure not to hook center projection of 2 spread springs

on same shifting insert.

13. Press in 5th-6th synchronizer hub assembly using the press

stand.

CAUTION:

Align grooves of 5th-6th shifting insert and 5th baulk ring.

A

:Transaxle front side

B

:Transaxle rear side

PCIB1883E

A

: 5th input gear side

B

: 6th input gear side

PCIB1884E

SCIA1083E

SCIA0928E