Nissan Qashqai J11. Manual - part 647

TRANSAXLE ASSEMBLY

TM-163

< UNIT DISASSEMBLY AND ASSEMBLY >

[6MT: RS6F52A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

3.

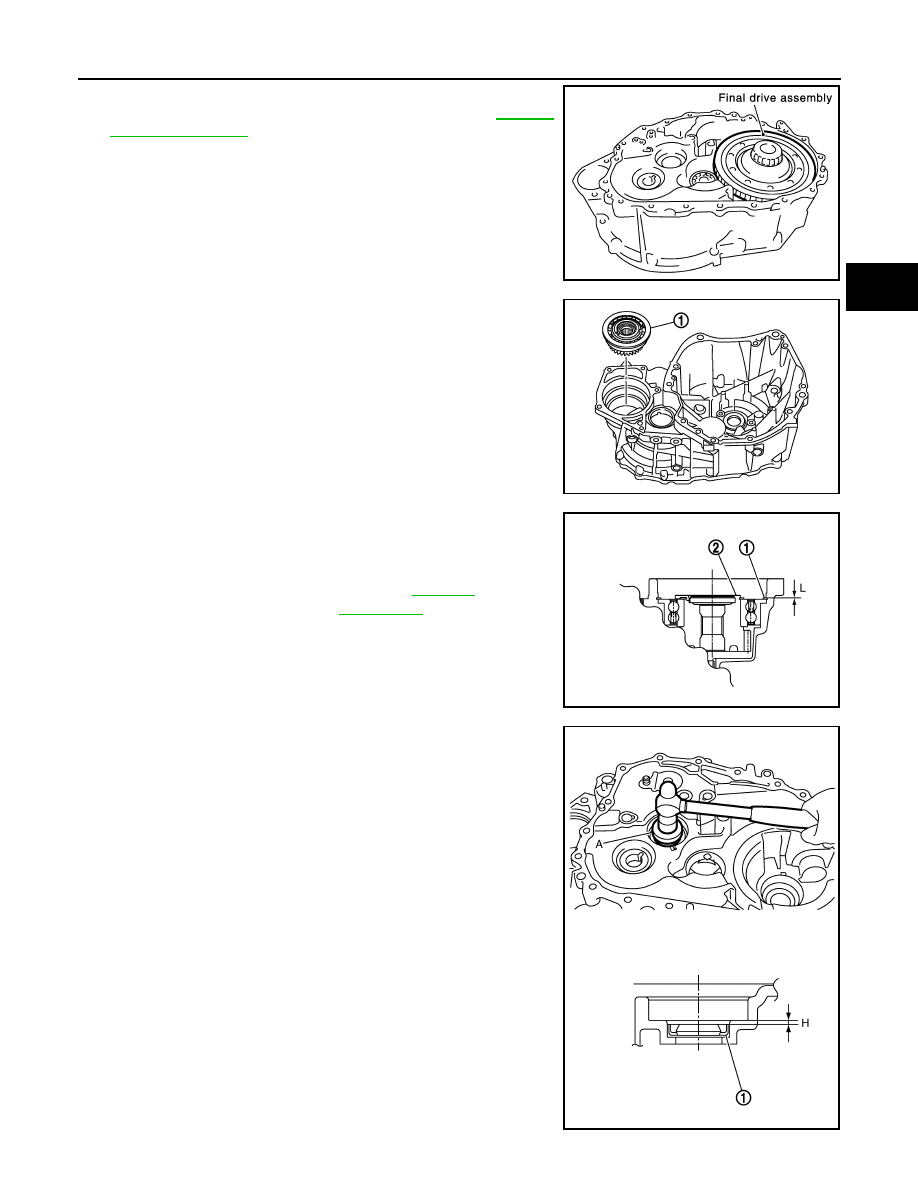

Install final drive assembly into clutch housing.

4.

Select differential side bearing adjusting shim. Refer to

CAUTION:

Never select differential side bearing adjusting shim with

output gear assembly installed on clutch housing.

5.

Remove final drive assembly.

6.

Turn clutch housing upside down as shown in the figure. And

then install output gear assembly (1) into clutch housing.

CAUTION:

• Gently install it, aligning the clutch housing hole with the

center of output gear assembly.

• Install output gear assembly, straightening it with a mag-

net.

• Never damage clutch housing and output gear assembly.

7.

Install snap ring (1) onto clutch housing and make sure that end

play (gap between snap ring and groove) of output gear assem-

bly (2) satisfies the standard value.

CAUTION:

• Only one snap ring can be selected.

• Never reuse snap ring.

• Never damage clutch housing.

8.

Install input shaft oil seal (1) to clutch housing using the drift (A)

[SST: ST35321000].

CAUTION:

• Never reuse input shaft oil seal.

• When installing, never incline input shaft oil seal.

• Never damage clutch housing.

SCIA0888E

JPDIC0074ZZ

End play standard value

“L”

: Refer to

.

JPDIC0043ZZ

Dimension “H”

: 1.1 - 2.1 mm (0.043 - 0.083 in)

PCIB1814E