Nissan Qashqai J11. Manual - part 643

AIR BREATHER HOSE

TM-147

< REMOVAL AND INSTALLATION >

[6MT: RS6F52A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

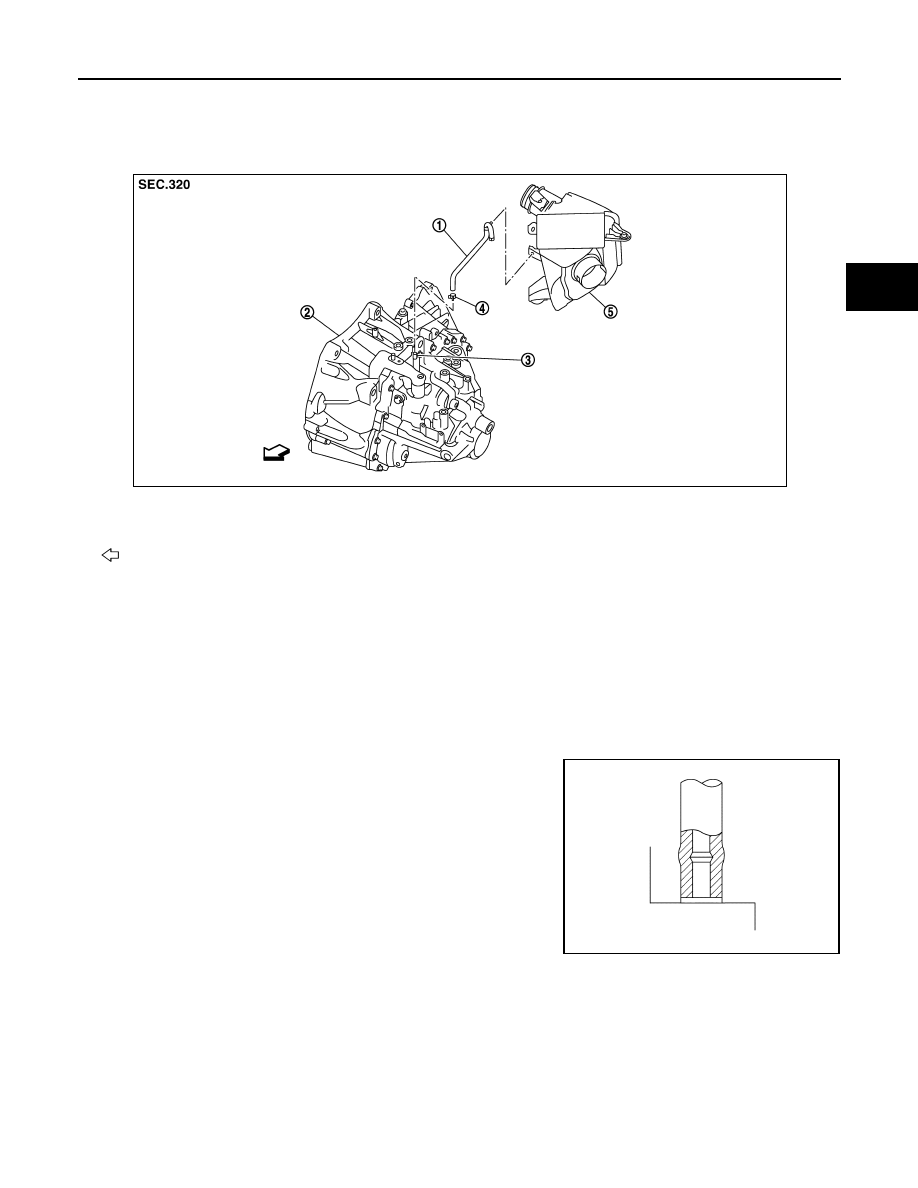

AIR BREATHER HOSE

Exploded View

INFOID:0000000010288507

Removal and Installation

INFOID:0000000010288508

REMOVAL

Refer to the figure for removal procedure.

INSTALLATION

Refer to the figure for installation procedure.

CAUTION:

• Make sure there are no pinched or restricted areas on the air breather hose caused by bending or

winding when installing it.

• Be sure to insert air breather hose into air breather tube until

hose end reaches the tube's base.

• Set air breather hose with painted mark facing forward.

• Install air breather hose to air cleaner case by fully inserting

the clip.

1.

Air breather hose

2.

Transaxle assembly

3.

Air breather tube

4.

Clamp

5.

Air cleaner case

: Vehicle front

JPDIC0051ZZ

SCIA2663J