Nissan Qashqai J11. Manual - part 405

ECK-180

< DTC/CIRCUIT DIAGNOSIS >

[K9K]

P0002 FUEL PRESSURE

4.

CHECK FOR FUEL LEAK

Check for fuel leakage at fuel circuit.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair or replace malfunctioning parts.

5.

CHECK HIGH PRESSURE FUEL PUMP

Check high pressure fuel pump. Refer to

ECK-180, "Component Inspection (High Pressure Fuel Pump)"

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Replace error-detected parts.

6.

CHECK FUEL INJECTOR

Check fuel injector. Refer to

ECK-180, "Component Inspection (Fuel Injector)"

.

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> Replace error-detected parts.

7.

CHECK FUEL RAIL PRESSURE LIMITER

Check fuel rail pressure limiter.

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-41, "Intermittent Incident"

.

NO

>> Replace error-detected parts.

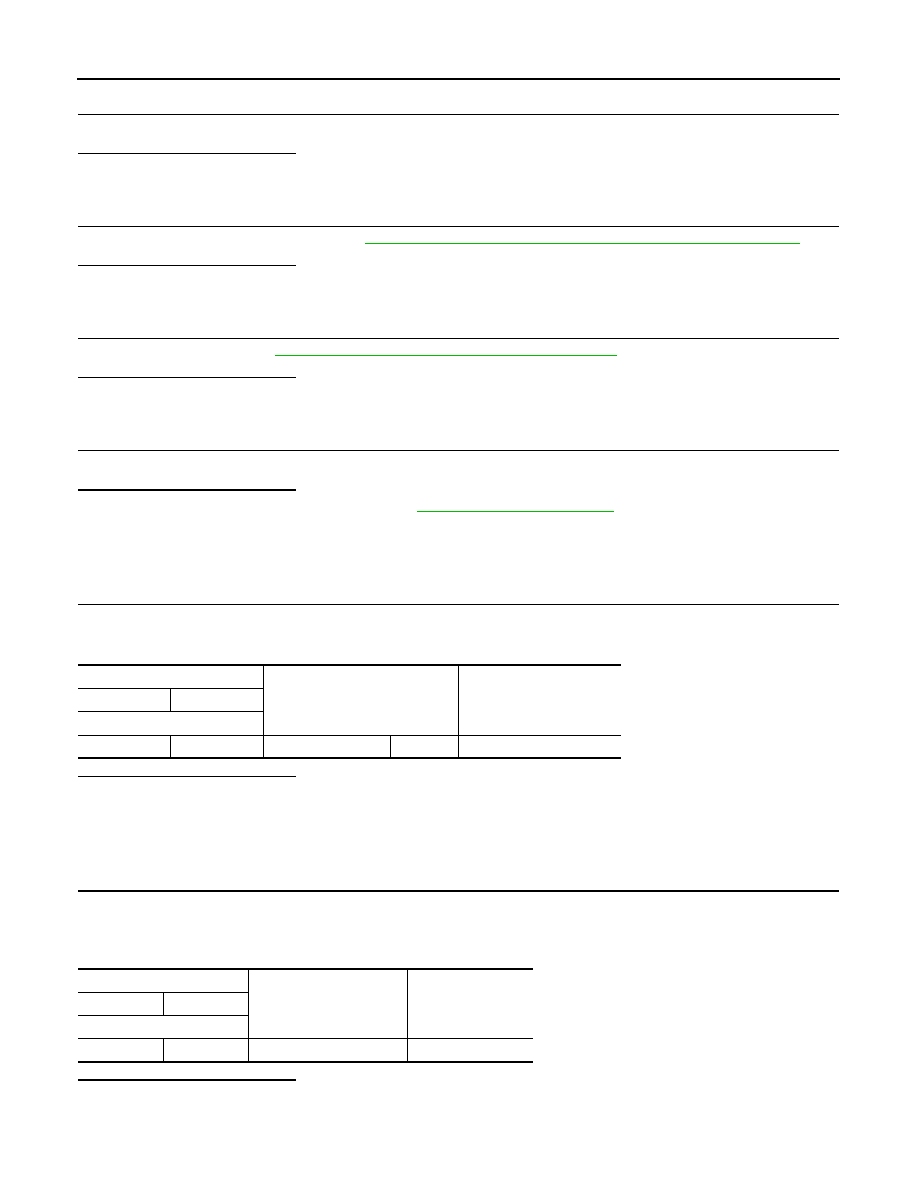

Component Inspection (High Pressure Fuel Pump)

INFOID:0000000010289747

1.

CHECK HIGH PRESSURE FUEL PUMP

1.

Disconnect high pressure fuel pump harness connector.

2.

Check the resistance between high pressure fuel pump terminals as follows.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace high pressure fuel pump.

Component Inspection (Fuel Injector)

INFOID:0000000010289748

1.

CHECK FUEL INJECTOR

1.

Turn ignition switch OFF.

2.

Disconnect fuel injector harness connector.

3.

Check the resistance between fuel injector terminals.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace fuel injector.

High pressure fuel pump

Condition

Resistance

+

-

Terminal

1

2

Temperature

°

C (

°

F)

20 (68)

2.55 - 2.81

Ω

Fuel injector

Condition

Resistance

+

−

Terminal

1

2

Temperature: 20

°

C (68

°

F)

150 – 250k

Ω