Nissan Qashqai J11. Manual - part 218

ECH-170

< DTC/CIRCUIT DIAGNOSIS >

[HRA2DDT]

P0120 TP SENSOR

P0120 TP SENSOR

DTC Logic

INFOID:0000000010379064

DTC DETECTION LOGIC

NOTE:

If DTC P0120 is displayed with DTC P0641 or P0651, first perform the trouble diagnosis for DTC P0641 or

P0651. Refer to

.

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

Turn ignition switch OFF and wait at least 12 minutes.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1.

Turn ignition switch ON and wait at least 12 minutes.

2.

Check DTC.

Is DTC detected?

YES

>> Proceed to

ECH-170, "Diagnosis Procedure"

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000010379065

1.

CHECK ECM HARNESS CONNECTOR CONNECTION

1.

Turn ignition switch OFF.

2.

Check ECM connector connection F17.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace ECM connector connection.

2.

CHECK ELECTRIC THROTTLE CONTROL ACTUATOR HARNESS CONNECTOR CONNECTION

Check electric throttle control actuator harness connector connection F46.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair or replace electric throttle control actuator harness connector connection.

3.

CHECK ELECTRIC THROTTLE CONTROL ACTUATOR POWER SUPPLY CIRCUIT

1.

Disconnect electric throttle control actuator harness connector.

2.

Check the continuity between electric throttle control actuator harness connector and ECM harness con-

nector.

3.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 4.

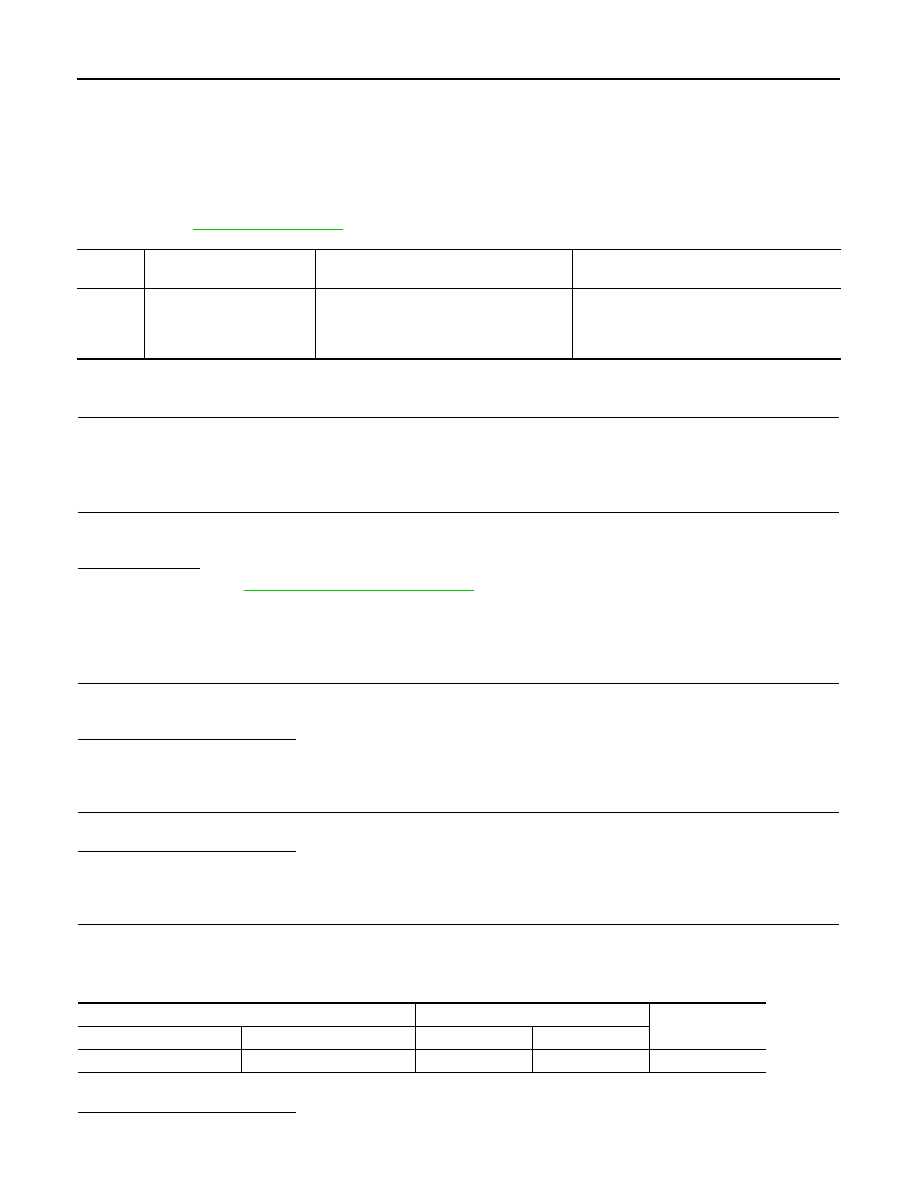

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0120

THROTTLE POSI SEN

[P0120]

[Throttle position sensor

(P0120)]

Implausible TP sensor position for 0.19 sec-

ond or more.

• Harness or connectors

(Throttle position sensor circuit is open or

shorted.)

• Throttle position sensor

Electric throttle control actuator

ECM

Continuity

Connector

Terminal

Connector

Terminal

F46

5

F17

65

Existed