Content .. 1744 1745 1746 1747 ..

Nissan Qashqai J11. Manual - part 1746

EXL-286

< DTC/CIRCUIT DIAGNOSIS >

[HALOGEN HEADLAMP]

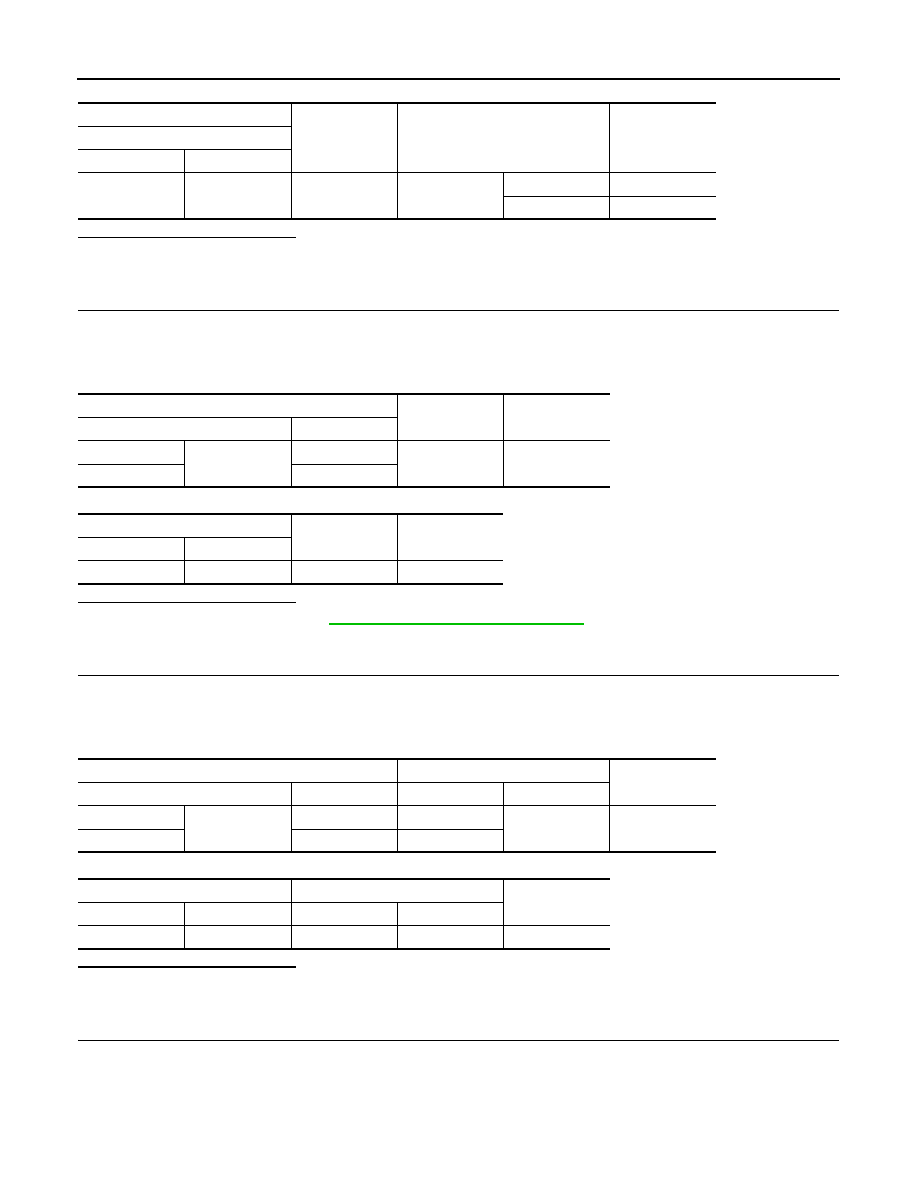

STOP LAMP CIRCUIT

High-mounted stop lamp

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> GO TO 8.

8.

CHECK STOP LAMP / HIGH-MOUNTED STOP LAMP POWER SUPPLY CIRCUIT (SHORT)

1.

Turn ignition switch OFF.

2.

Disconnect BCM connector.

3.

Check continuity between BCM harness connector and ground.

Stop lamp

High-mounted stop lamp

Is the inspection result normal?

YES

>> Replace BCM. Refer to

BCS-132, "Removal and Installation"

.

NO

>> Repair or replace harness.

9.

CHECK STOP LAMP / HIGH-MOUNTED STOP LAMP POWER SUPPLY CIRCUIT (OPEN)

1.

Turn ignition switch OFF.

2.

Disconnect BCM connector.

3.

Check continuity between BCM harness connector and each stop lamp harness connector.

Stop lamp

High-mounted stop lamp

Is the inspection result normal?

YES

>> GO TO 10.

NO

>> Repair or replace harness.

10.

CHECK STOP LAMP / HIGH-MOUNTED STOP LAMP GROUND CIRCUIT

Check continuity between each stop lamp harness connector and ground.

+

-

Test item

Voltage

(Approx.)

BCM

Connector

Terminal

B4

39

Ground

STOP LAMP 3

On

9 – 16 V

Off

0 V

BCM

—

Continuity

Connector

Terminal

RH

B3

134

Ground

Not existed

LH

129

BCM

—

Continuity

Connector

Terminal

B4

39

Ground

Not existed

BCM

Stop lamp / tail lamp

Continuity

Connector

Terminal

Connector

Terminal

RH

B3

134

B79

1

Existed

LH

129

B22

BCM

High-mounted stop lamp

Continuity

Connector

Terminal

Connector

Terminal

B4

39

B17

2

Existed