Nissan Qashqai J11. Manual - part 129

CYLINDER BLOCK

EM-455

< UNIT DISASSEMBLY AND ASSEMBLY >

[R9M]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

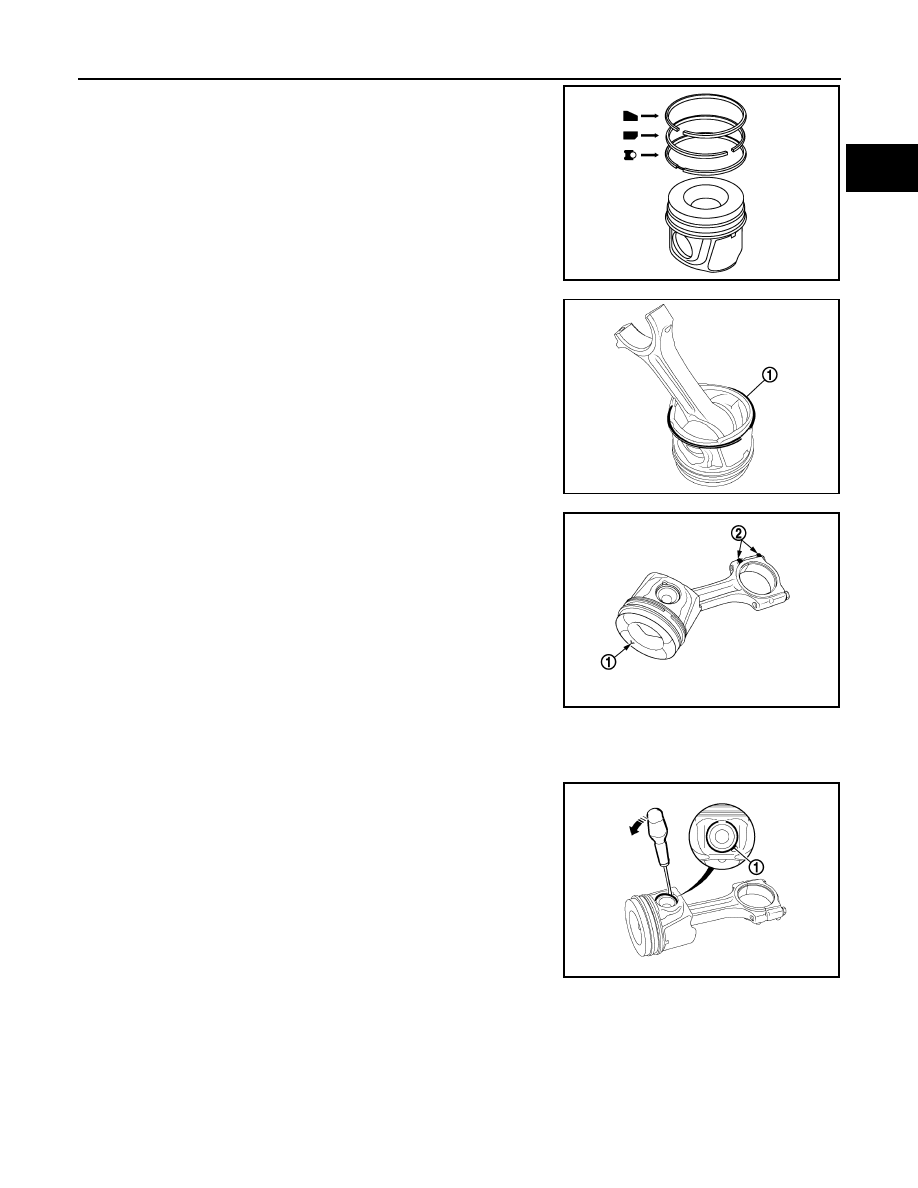

• Position each ring with the gap as shown in the figure referring

to the piston front mark.

8.

• Fit the scraper ring (1) with the hand by way of the con rod.

9.

• Lubricate piston pin with engine oil.

• Position the con rod in relation to the piston (piston marking (1)

"V" is opposite the machined bosses (2) on the big end)

NOTE:

Piston marking V engine flywheel end, Con rod marking

(machined bosses) timing end.

10. Engage the pin in the piston and in the samll end.

NOTE:

Check that the piston pin slides and rotates easily in the piston and the small end.

11.

• Refit the locking spring ring to the piston pin using a flat screw-

driver (apply pressure in the groove (1)).

NOTE:

Position the opening in the locking spring ring towards the piston

crown.

JPBIA1058ZZ

E1BIA0503ZZ

E1BIA0504ZZ

E1BIA0505ZZ