Nissan Qashqai J11. Manual - part 40

CYLINDER BLOCK

EM-99

< UNIT DISASSEMBLY AND ASSEMBLY >

[HRA2DDT]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

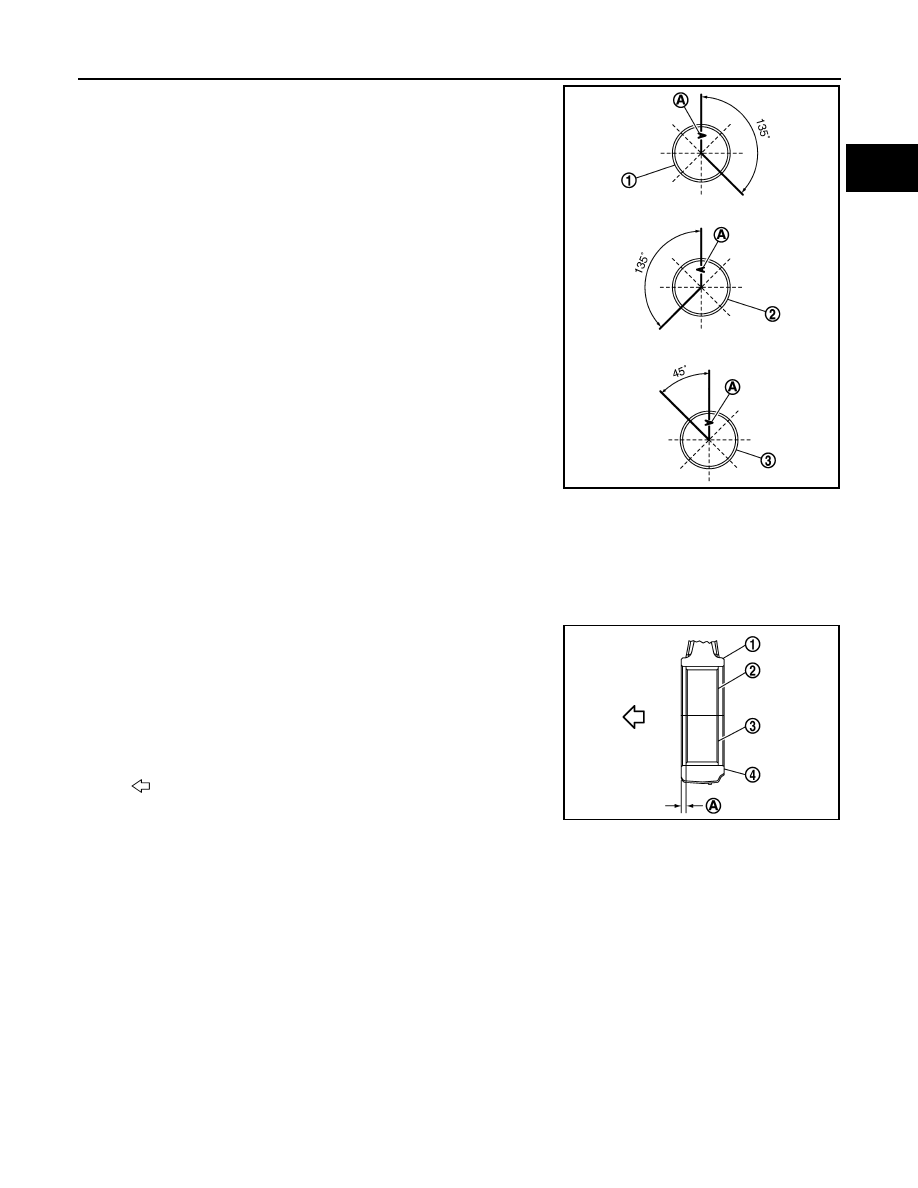

• Position the 3 parts oil ring with the end gap placed as shown

in the figure referring to the piston front mark (A).

9.

Install connecting rod bearings to connecting rod and connecting rod cap.

• When installing connecting rod bearings, apply new engine oil to the bearing surface (inside). Do not

apply engine oil to the back surface, but thoroughly clean it.

• Install the bearing in the center position.

NOTE:

There is no stopper tab.

• Check that the oil holes on connecting rod and connecting rod bearing are aligned.

• Install the connecting rod in the dimension as shown in the fig-

ure.

NOTE:

Install the connecting rod bearing in the center position with

the dimension as shown in the figure. For service operation, the center position can be checked visually.

10. Install piston and connecting rod assembly to crankshaft.

• Position crankshaft pin corresponding to connecting rod to be installed onto the bottom dead center.

• Apply new engine oil sufficiently to the cylinder bore, piston and crankshaft pin.

• Match the cylinder position with the cylinder number on connecting rod to install.

1

: Upper rail

2

: Spring

3

: Lower rail

E1BIA1108ZZ

1

: Connecting rod

2

: Connecting rod bearing (upper)

3

: Connecting rod bearing (lower)

4

: Connecting rod cap

A

: 2.05 - 2.07 mm (0.0807 - 0.0815 in)

: Engine front

PBIC4169E