Nissan Qashqai J11. Manual - part 38

OIL PAN (UPPER)

EM-91

< UNIT DISASSEMBLY AND ASSEMBLY >

[HRA2DDT]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

c.

Insert the seal cutter [SST: KV10111100] (1) between the oil pan

(upper) and cylinder block. Slide seal cutter by tapping on the

side of tool with a hammer.

CAUTION:

• Be careful not to damage the mating surface.

• A more adhesive liquid gasket is applied compared to pre-

vious types when shipped, so it should not be forced off

using a screwdriver, etc. outside the indicated location.

d.

Remove oil pan (upper)

e.

Remove oil pan (upper) O-ring (1).

11. Remove rear oil seal from crankshaft. Refer to

EM-87, "REAR OIL SEAL : Removal and Installation"

INSTALLATION

1.

Install the oil pan (upper) in the following procedure:

a.

Use scraper to remove old liquid gasket from mating surfaces.

• Also remove the old liquid gasket from mating surface of cylinder block.

• Remove old liquid gasket from the bolt holes and threads.

CAUTION:

Never scratch or damage the mating surfaces when cleaning off old liquid gasket.

b.

Install new oil pan (upper) oil seal.

c.

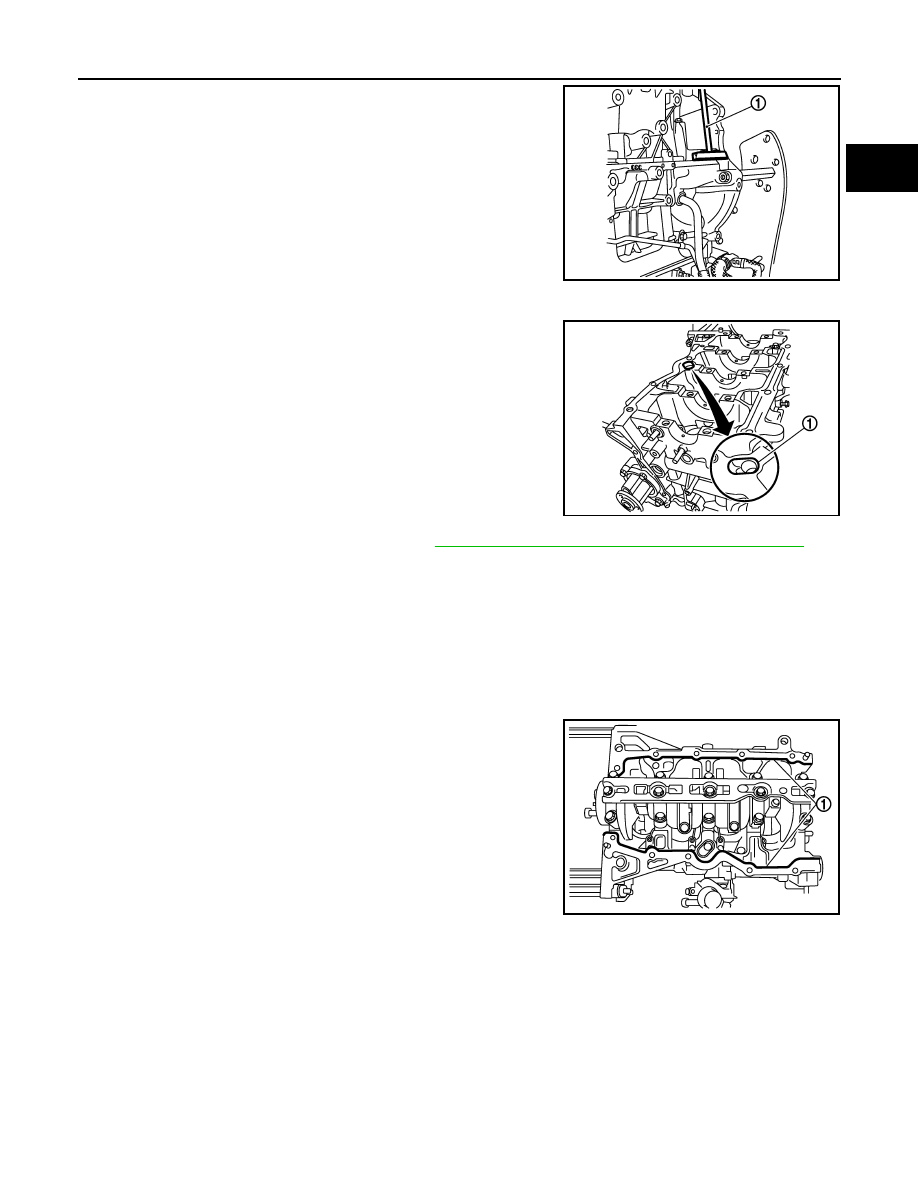

Apply a continuous bead of liquid gasket (1) with the tube

presser (commercial service tool) to areas as shown in the fig-

ure.

Use Genuine Liquid Gasket or equivalent.

CAUTION:

Attaching should be done within 5 minutes after coating.

E1BIA1047ZZ

E1BIA1048ZZ

Bead of liquid gasket diameter

:

φ

4.0 - 5.0 mm (0.157 - 0.197 in)

Distance from inside edge

: 7.5 - 9.5 mm (0.295 - 0.374 in)

E1BIA1049ZZ