Nissan Qashqai J11. Manual - part 36

CAMSHAFT

EM-83

< UNIT DISASSEMBLY AND ASSEMBLY >

[HRA2DDT]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

• If it exceeds the limit, replace either or both camshaft and cylinder head.

NOTE:

Camshaft brackets cannot be replaced as single parts, because they are machined together with cylinder

head. Replace whole cylinder head assembly.

Camshaft End Play

1.

Install camshaft in cylinder head. Refer to

EM-77, "Removal and Installation"

2.

Install a dial indicator (A) in thrust direction on front end of cam-

shaft. Measure the camshaft end play on the dial indicator when

camshaft is moved forward/backward (in direction to axis).

Valve Lifter

Check if surface of valve lifter has any wear or cracks.

• If anything above is found, replace valve lifter. Refer to

.

Valve Lifter Clearance

VALVE LIFTER OUTER DIAMETER

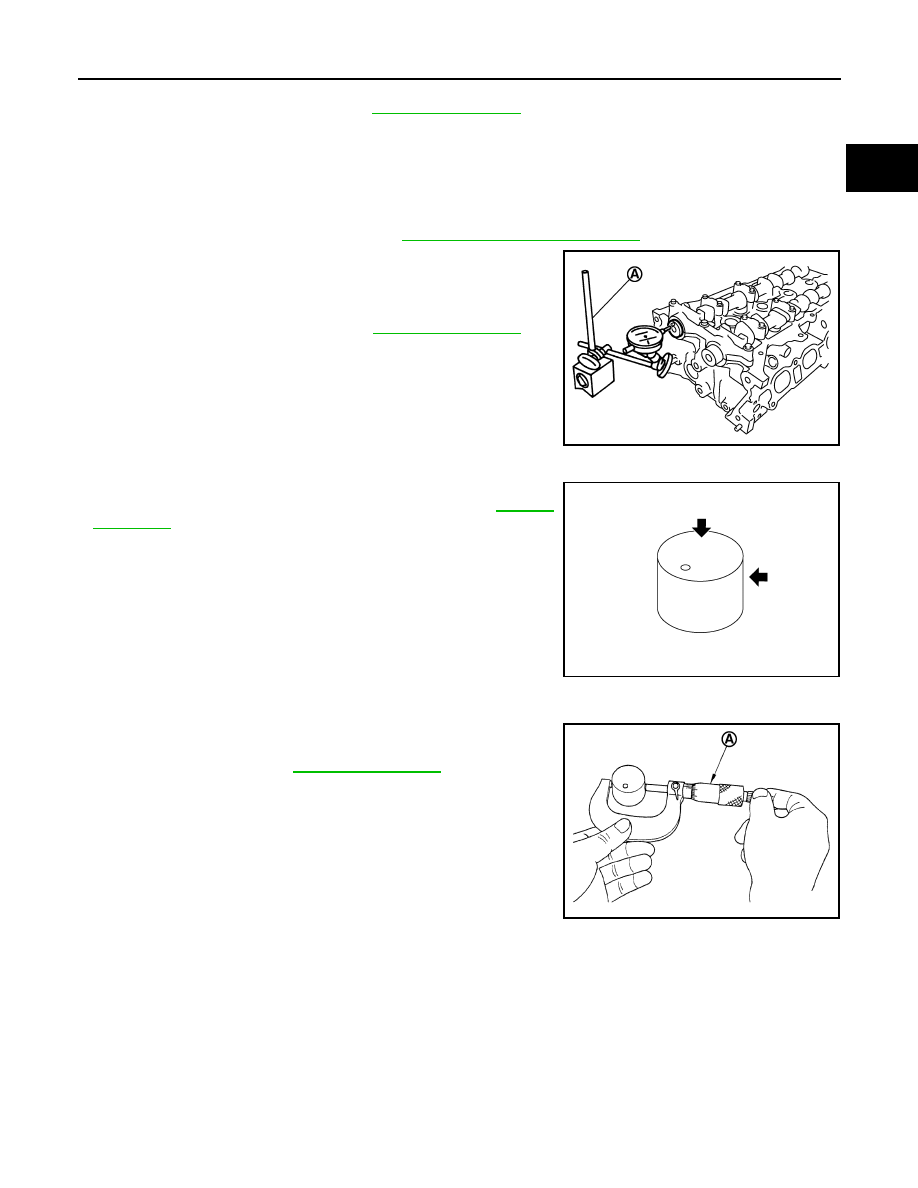

• Measure the outer diameter of valve lifter with a micrometer (A).

VALVE LIFTER HOLE DIAMETER

Standard and Limit

: Refer to

.

Standard and Limit

: Refer to

.

PBIC3694E

KBIA0182E

Standard

: Refer to

.

PBIC3185J