Nissan Qashqai J11. Manual - part 39

CYLINDER BLOCK

EM-95

< UNIT DISASSEMBLY AND ASSEMBLY >

[HRA2DDT]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

Identify installation positions, and store them without mixing them up.

8.

Remove piston rings form piston.

• Before removing piston rings, check the piston ring side clearance. Refer to

.

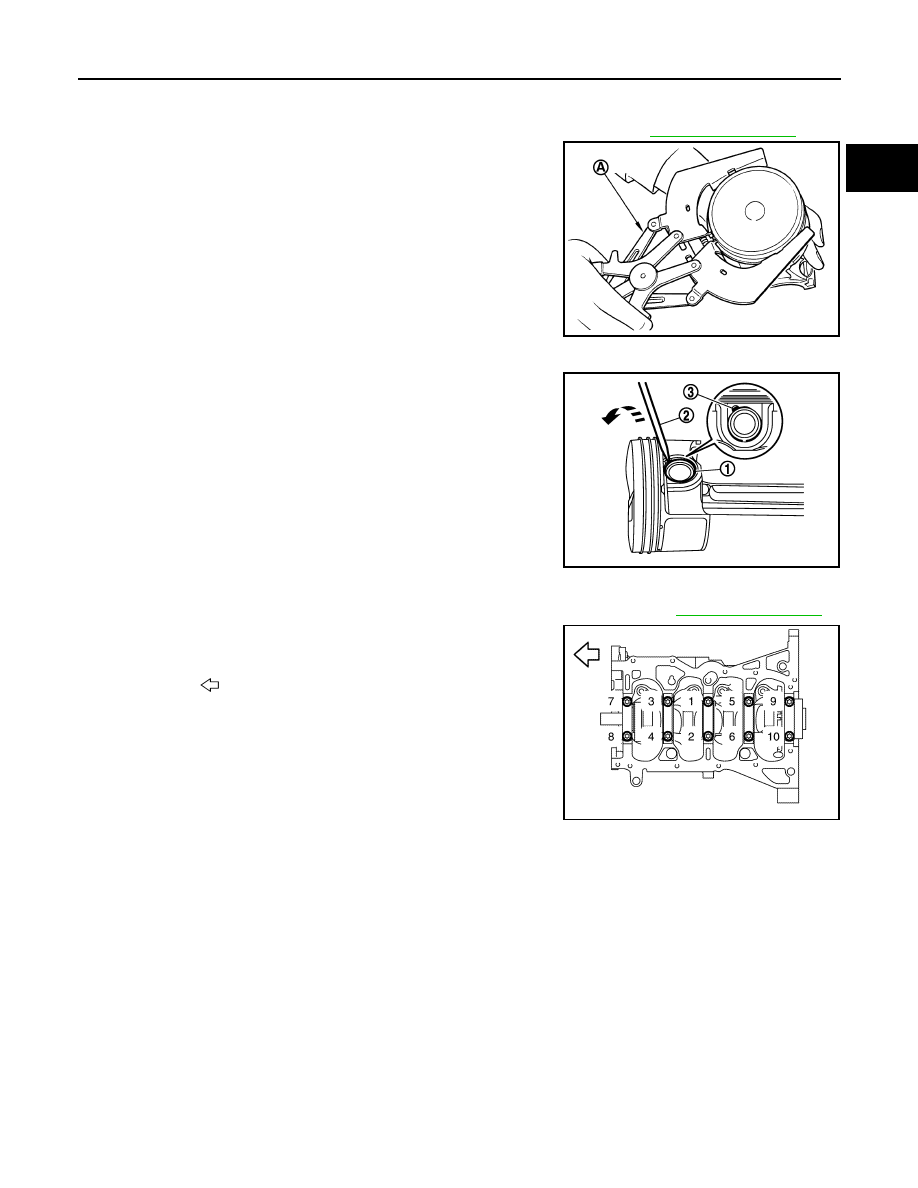

• Use a piston ring expander (commercial service tool) (A).

CAUTION:

• When removing piston rings, be careful not to damage

the piston.

• Be careful not to damage piston rings by expanding

them excessively.

9.

Remove piston from connecting rod.

• Remove snap ring (1) using a screwdriver (2) placed in the

piston groove (3).

• Release the piston pin.

CAUTION:

• Be careful not to damage the piston and connecting rod.

• Identify installation positions, and store them without

mixing them up.

10. Remove the main bearing cap in the following procedure.

• Measure crankshaft end play before loosening main bearing cap bolts. Refer to

a.

Loosen and remove bolts in several steps in reverse of the

numerical order as shown in the figure.

b.

Remove the main bearing cap from the cylinder block while tapping lightly with a plastic hammer.

11. Remove crankshaft.

CAUTION:

• When setting crankshaft on a flat floor surface, use a block of wood to avoid interference

between signal plate and the floor surface.

12. Pull rear oil seal out from rear end of crankshaft.

13. Remove main bearings and thrust bearings from cylinder block and main bearing cap.

CAUTION:

Identify installation positions, and store them without mixing them up.

14. Remove oil jets.

CAUTION:

Identify installation positions, and store them without mixing them up.

ASSEMBLY

1.

Fully air-blow engine coolant and engine oil passages in cylinder block, cylinder bore and crankcase to

remove any foreign material.

PBIC3233J

E1BIA1104ZZ

: Engine front

JPBIA4203ZZ