Nissan Juke F15. Manual - part 972

LU-18

< UNIT DISASSEMBLY AND ASSEMBLY >

[MR FOR NISMO RS MODELS]

OIL PUMP

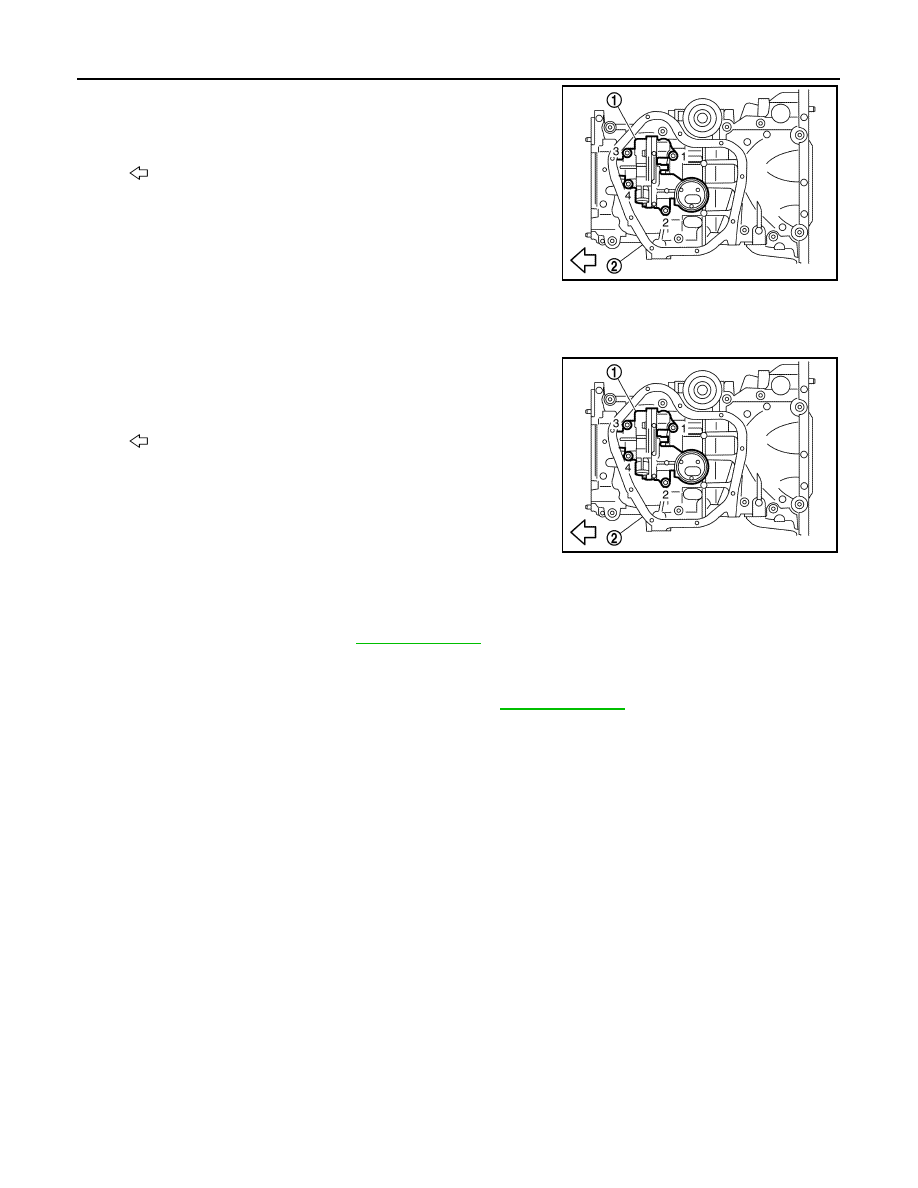

• Loosen bolts in reverse order as shown in the figure.

INSTALLATION

Note the following, and install in the reverse order of removal.

Oil Pump

• Tighten bolts in numerical order as shown in the figure.

Inspection

INFOID:0000000012197482

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer to

.

2. Start the engine, and check that there is no leakage of engine oil.

3. Stop the engine and wait for 10 minutes.

4. Check the engine oil level, and adjust the level. Refer to

.

1

: Oil pump

2

: Oil pan (upper)

: Engine front

JPBIA4451ZZ

1

: Oil pump

2

: Oil pan (upper)

: Engine front

JPBIA4451ZZ