Nissan Juke F15. Manual - part 663

EM-206

< REMOVAL AND INSTALLATION >

[MR EXCEPT FOR NISMO RS MODELS]

HIGH PRESSURE FUEL PUMP AND FUEL HOSE

ii.

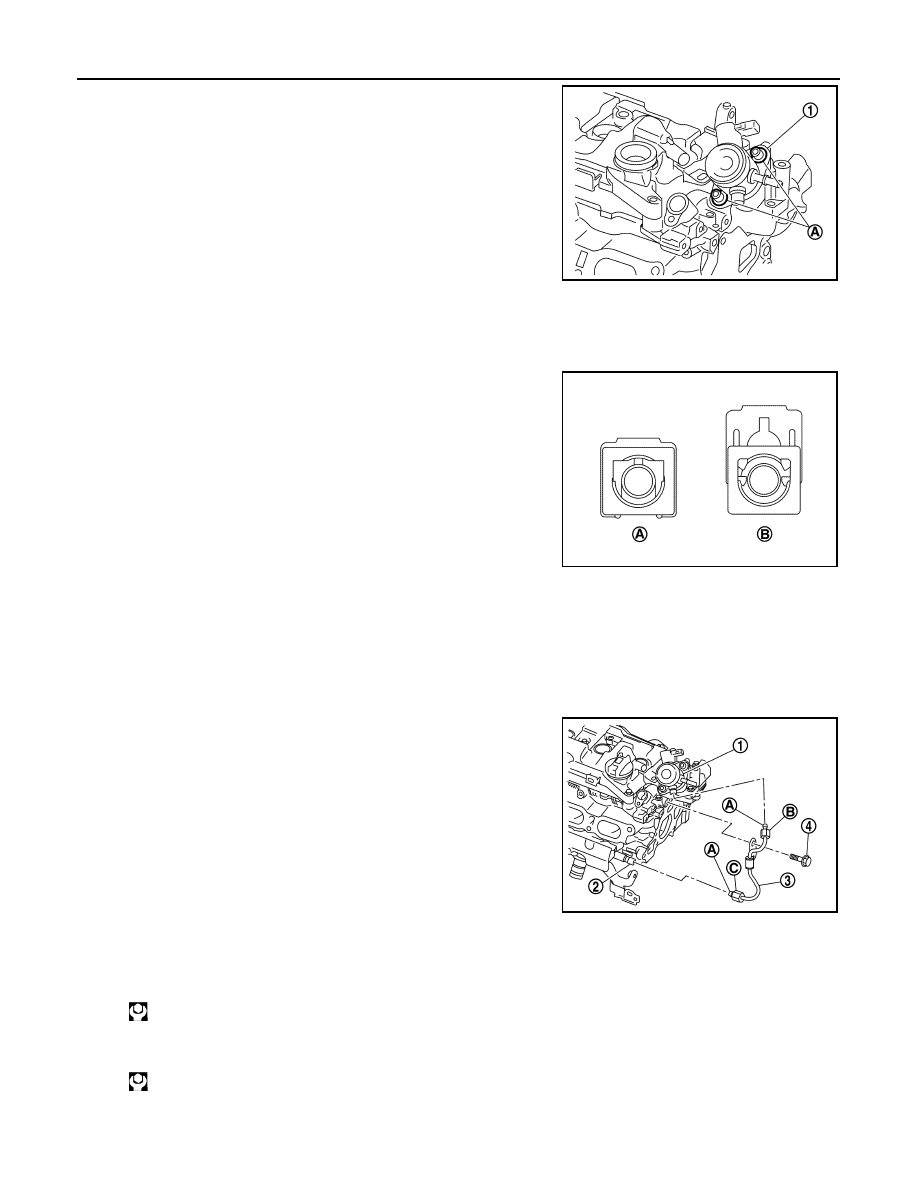

Temporarily tighten the bolts (A) by hand, and then tighten the

bolts (A) alternately one rotation at a time until the high-pressure

fuel pump flange (1) contacts the camshaft bracket.

iii. Tighten the bolts (A) to the specified torque.

2. Follow the procedure below and install the fuel feed hose.

a. Check the fuel tube and quick connector for damage or foreign material.

b. Check that the axis is lined up when inserting the quick connector into the fuel tube.

c.

Insert the retainer until a “click” sound is heard, and check that

the retainer is securely installed. Pull the quick connector by

hand and check that it is locked.

CAUTION:

If the retainer cannot be inserted smoothly, the quick con-

nector may not be connected correctly. Remove the quick

connector and then check the connection of quick connec-

tor again.

d. Secure fuel feed hose to clamp.

3. Follow the procedure below and install the high-pressure fuel tube.

CAUTION:

• Never reuse the high-pressure fuel hose. Always use a new one.

• If scratches or damage on the end of the high-pressure fuel tube are present, never use it.

• Always tighten in the correct order to the specified tightening torque.

a. Apply new engine oil to high-pressure fuel tube flare nipple (A)

and flare nuts (B),(C).

CAUTION:

Check that there is no foreign material on the high-pressure

fuel tube flare nipple and flare nuts.

b. Temporarily tighten until the high-pressure fuel tube (3) flare

nuts (B) and (C) contact the seat.

CAUTION:

When temporarily tightening the flare nuts, insert them so that they are aligned with the center of

the pipe.

c.

Tighten the high-pressure fuel tube bracket mounting bolt (4) to the specified torque.

d. Tighten flare nuts to the specified torque in the order of (B) and (C).

CAUTION:

Before tightening, check that the tool is attached at a 90

° angle to the flare nut when working.

JSBIA1673ZZ

A

: Engaged condition

B

: Not engaged condi-

tion

JPBIA4381ZZ

1

: High-pressure fuel pump

2

: Fuel rail

: 25.0 N·m (2.6 kg-m, 18 ft-lb)

: 36.0 N·m (3.7 kg-m, 27 ft-lb)

JSBIA6005ZZ