Nissan Juke F15. Manual - part 661

EM-198

< REMOVAL AND INSTALLATION >

[MR EXCEPT FOR NISMO RS MODELS]

INTAKE MANIFOLD

1. Remove the engine cover. Refer to

EM-191, "Removal and Installation"

2. Pull out oil level gauge.

CAUTION:

After removal, block the oil level gauge guide openings with tape so that no foreign material enters

inside engine.

3. Disconnect the turbocharger boost sensor harness connector. Refer to

.

4. Remove air inlet tube 1, air inlet tube 2, and the air inlet hose. Refer to

5. Disconnect the water hose from the electric throttle control actuator.

• Install a clamp or plug onto the water hose for preventing coolant leakage.

CAUTION:

Allow the engine to fully cool before starting operation.

NOTE:

This work is not necessary when only the intake manifold is removed.

6. Disconnect the harness connector from the electric throttle control actuator.

7. Remove electric throttle control actuator.

CAUTION:

• Never subject parts to impact.

• Never disassemble or adjust. (Disassembly of this part is prohibited.)

8. Disconnect the harness connector and EVAP hose from the EVAP purge volume control solenoid valve.

CAUTION:

Never subject parts to impact.

9. Disconnect the vacuum tube and vacuum hose.

10. Disconnect the PCV hose (intake manifold side).

11. Follow the procedure below and remove the intake manifold.

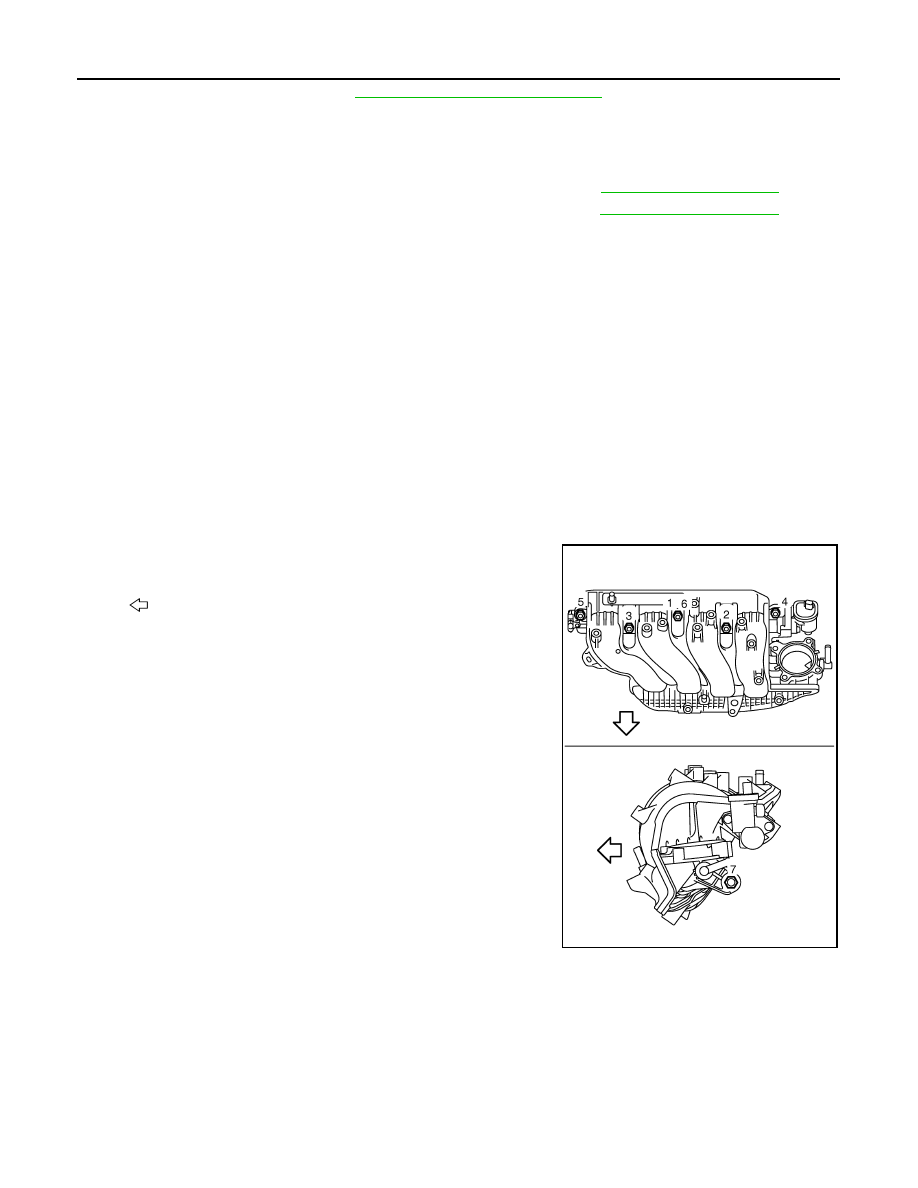

• Loosen and remove bolts in the reverse order of the numerical

order shown in the figure.

NOTE:

Disregard the numerical order No.6 in removal.

CAUTION:

Block the openings with tape so that no foreign material

enters the engine.

12. If necessary, remove the EVAP purge control solenoid valve from the intake manifold.

CAUTION:

Never subject parts to impact.

INSTALLATION

Note the following, and install in the reverse order of removal.

Intake Manifold

1. Install the gasket to the intake manifold mounting groove.

2. Follow the procedure below and install the intake manifold.

: Vehicle front

E1BIA1279ZZ