Nissan Juke F15. Manual - part 537

P0404 EGR VOLUME CONTROL VALVE

EC-961

< DTC/CIRCUIT DIAGNOSIS >

[MR EXCEPT FOR NISMO RS MODELS]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P0404 EGR VOLUME CONTROL VALVE

DTC Logic

INFOID:0000000012198455

DTC DETECTION LOGIC

NOTE:

If DTC P0404 is displayed with DTC P044A, or P044E, first perform trouble diagnosis for DTC P044A, or

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1. Start the engine when the following conditions are met.

2. Drive the vehicle at 50 km/h (32 MPH) or more for at least 5 seconds.

3. Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Proceed to

.

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000012198456

1.

CHECK EGR VOLUME CONTROL VALVE

Check the EGR volume control valve. Refer to

EC-961, "Component Inspection (EGR Volume Control Valve)"

.

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-45, "Intermittent Incident"

.

NO

>> Replace EGR volume control valve. Refer to

EC-600, "ENGINE CONTROL SYSTEM :

.

Component Inspection (EGR Volume Control Valve)

INFOID:0000000012198457

1.

CHECK EGR VOLUME CONTROL VALVE-1

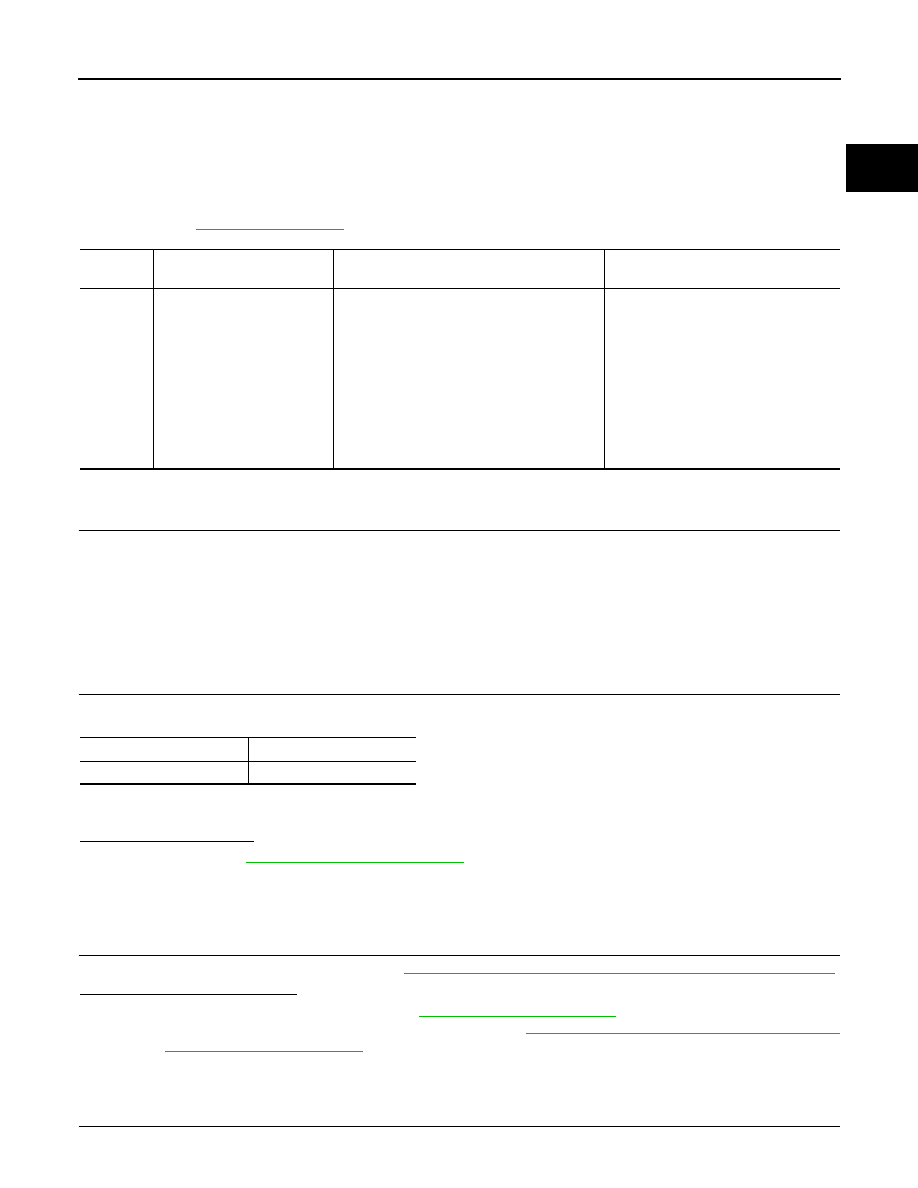

DTC No.

Trouble diagnosis name

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0404

EGR A CONTROL

(EGR A control circuit range/

performance)

• ECM detects that the current sent to the

EGR volume control valve motor is equal to

or more than the threshold value for 2 sec-

onds or more under the condition that the

target angle of EGR volume control valve is

constant.

• ECM detects that the difference between the

target angle of EGR volume control valve

and actual valve angle is equal to or more

than the threshold value for 5 seconds or

more.

• EGR volume control valve

• Foreigh objects interferes with EGR

volume control valve

Intake air temperature

0

°C (32°F) or more

Engine coolant temperature 75

°C (167°F) or more