Nissan Juke F15. Manual - part 489

ACCELERATOR PEDAL

EC-769

< BASIC INSPECTION >

[MR EXCEPT FOR NISMO RS MODELS]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

ACCELERATOR PEDAL

Work Procedure

INFOID:0000000012198280

1.

PERFORM ACCELERATOR PEDAL FORCE-I

1. Turn ignition switch OFF.

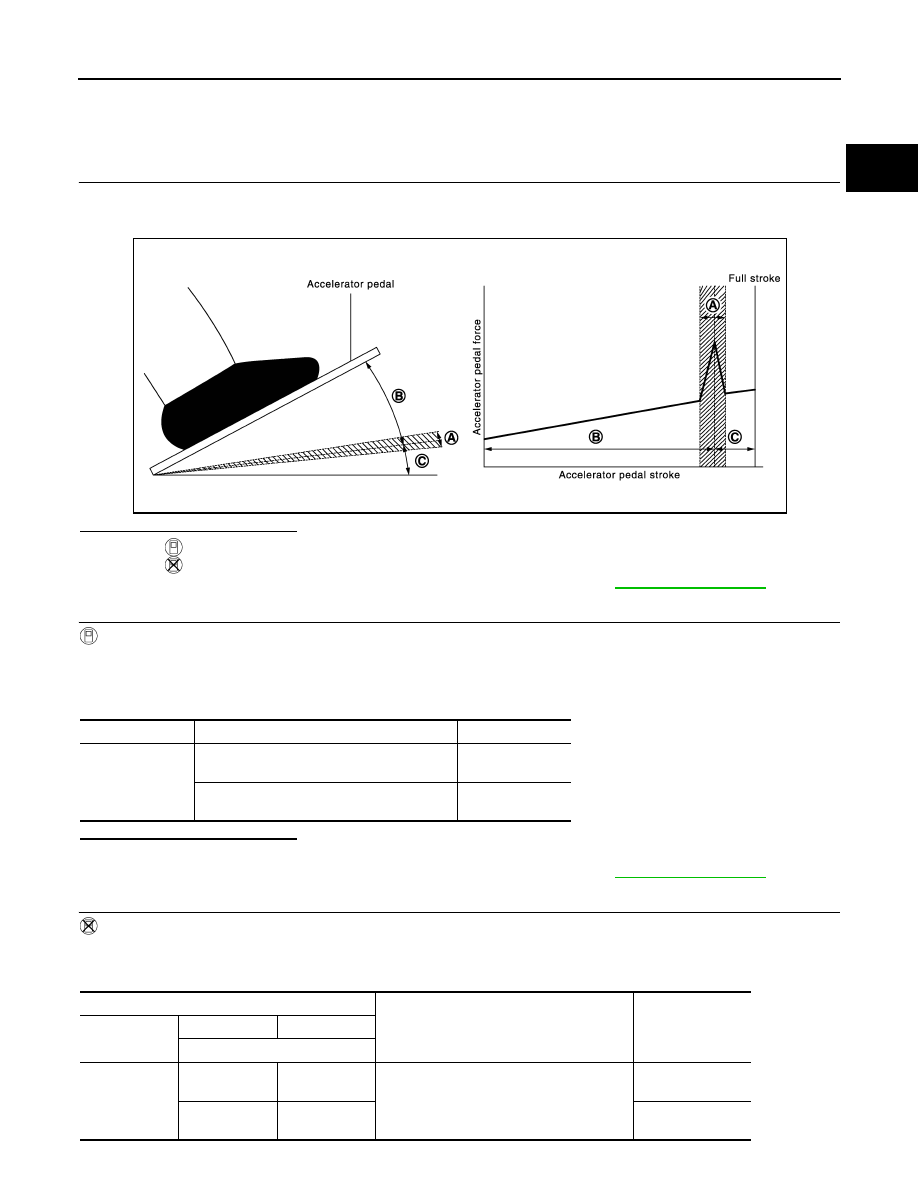

2. Depress the accelerator pedal and check if there is a specific point (A) in the pedal stroke where the pedal

force increase as shown in the figure.

Is the inspection result normal?

YES-1 >>

With CONSULT:GO TO 2.

YES-2 >>

Without CONSULT:GO TO 3.

NO

>> Perform Accelerator Pedal Released Position Learning. Refer to

.

2.

PERFORM ACCELERATOR PEDAL FORCE-II

With CONSULT

1. Turn ignition switch ON.

2. Select “KICKDOWN POS” in “DATA MONITOR” mode using CONSULT.

3. Check “KICKDOWN POS” indication under the following condition.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Perform Accelerator Pedal Released Position Learning. Refer to

.

3.

PERFORM ACCELERATOR PEDAL FORCE-III

Without CONSULT

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector and ground under the following conditions.

JMBIA1519GB

Monitor item

Condition

Indication

KICKDOWN POS

Depressing range of the accelerator pedal:

Within (B) as indicated in the figure

OFF

Depressing range of the accelerator pedal:

Within (C) as indicated in the figure

ON

ECM

Condition

Voltage

(Approx.)

Connector

+

–

Terminal

E19

150

(APP sensor 1)

151

Depressing range of the accelerator pedal:

Within (C) as indicated in the figure

3.9 - 4.7 V

143

(APP sensor 2)

144

1.95 - 2.4 V