Nissan Juke F15. Manual - part 488

BASIC INSPECTION

EC-765

< BASIC INSPECTION >

[MR EXCEPT FOR NISMO RS MODELS]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

BASIC INSPECTION

Work Procedure

INFOID:0000000012198279

1.

INSPECTION START

1. Check service records for any recent repairs that may indicate a related malfunction, or a current need for

scheduled maintenance.

2. Open engine hood and check the following:

-

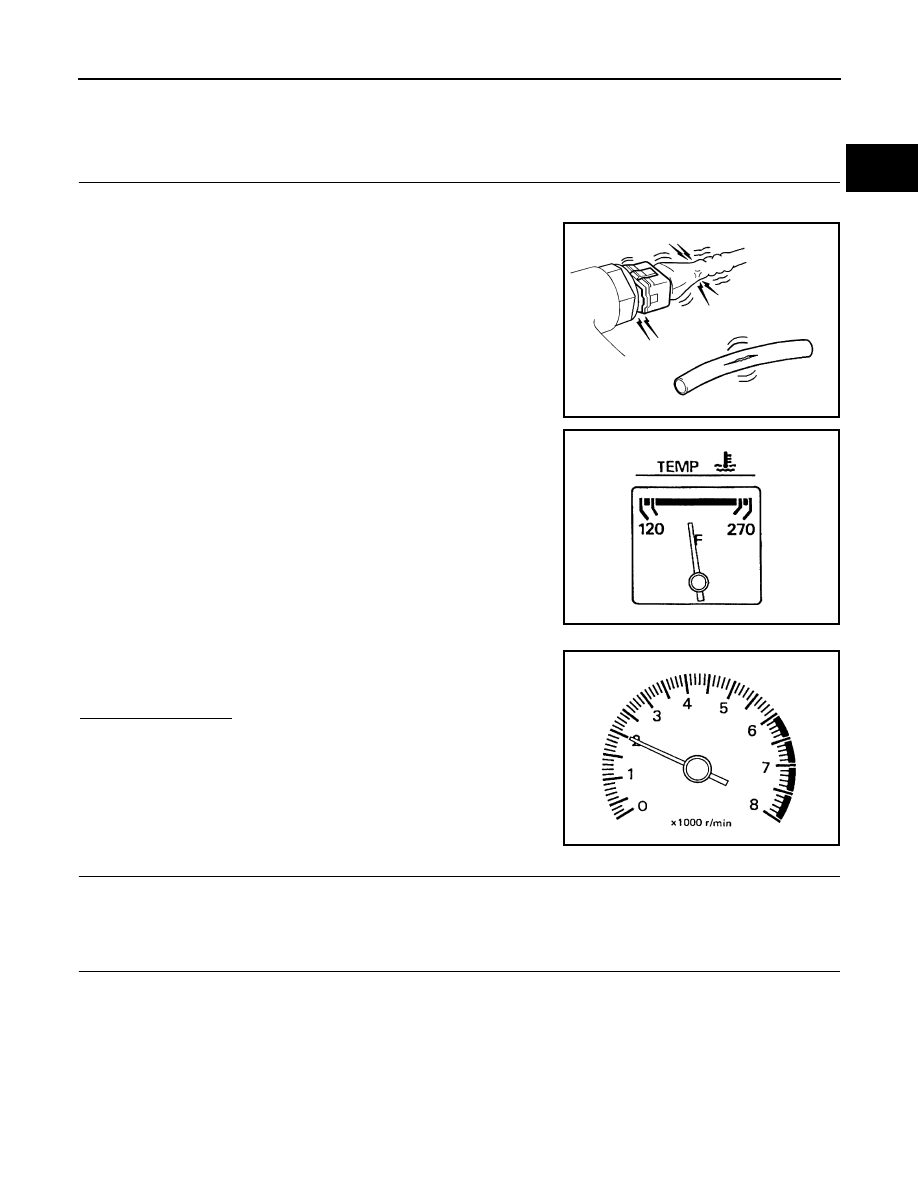

Harness connectors for improper connections

-

Wiring harness for improper connections, pinches and cut

-

Vacuum hoses for splits, kinks and improper connections

-

Hoses and ducts for leaks

-

Air cleaner clogging

-

Gasket

3. Confirm that electrical or mechanical loads are not applied.

-

Headlamp switch is OFF.

-

Air conditioner switch is OFF.

-

Rear window defogger switch is OFF.

-

Steering wheel is in the straight-ahead position, etc.

4. Start engine and warm it up until engine coolant temperature

indicator points the middle of gauge.

Ensure engine stays below 1,000 rpm.

5. Run engine at about 2,000 rpm for about 2 minutes under no

load.

6. Make sure that no DTC is displayed with CONSULT or GST.

Is any DTC detected?

YES

>> GO TO 2.

NO

>> GO TO 3.

2.

REPAIR OR REPLACE

Repair or replace components as necessary according to corresponding Diagnostic Procedure.

>> GO TO 3.

3.

CHECK TARGET IDLE SPEED

1. Run engine at about 2,000 rpm for about 2 minutes under no load.

SEF983U

SEF976U

SEF977U