Nissan Juke F15. Manual - part 273

RING GEAR SHAFT

DLN-97

< UNIT DISASSEMBLY AND ASSEMBLY >

[TRANSFER: TY21B]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

Disassembly

INFOID:0000000012199466

1. Remove transfer cover. Refer to

.

2. Remove transfer case oil seal (right and left).

3. Remove ring gear shaft assembly from transfer case. If ring gear shaft cannot be removed, remove as fol-

lows.

CAUTION:

Never damage transfer case.

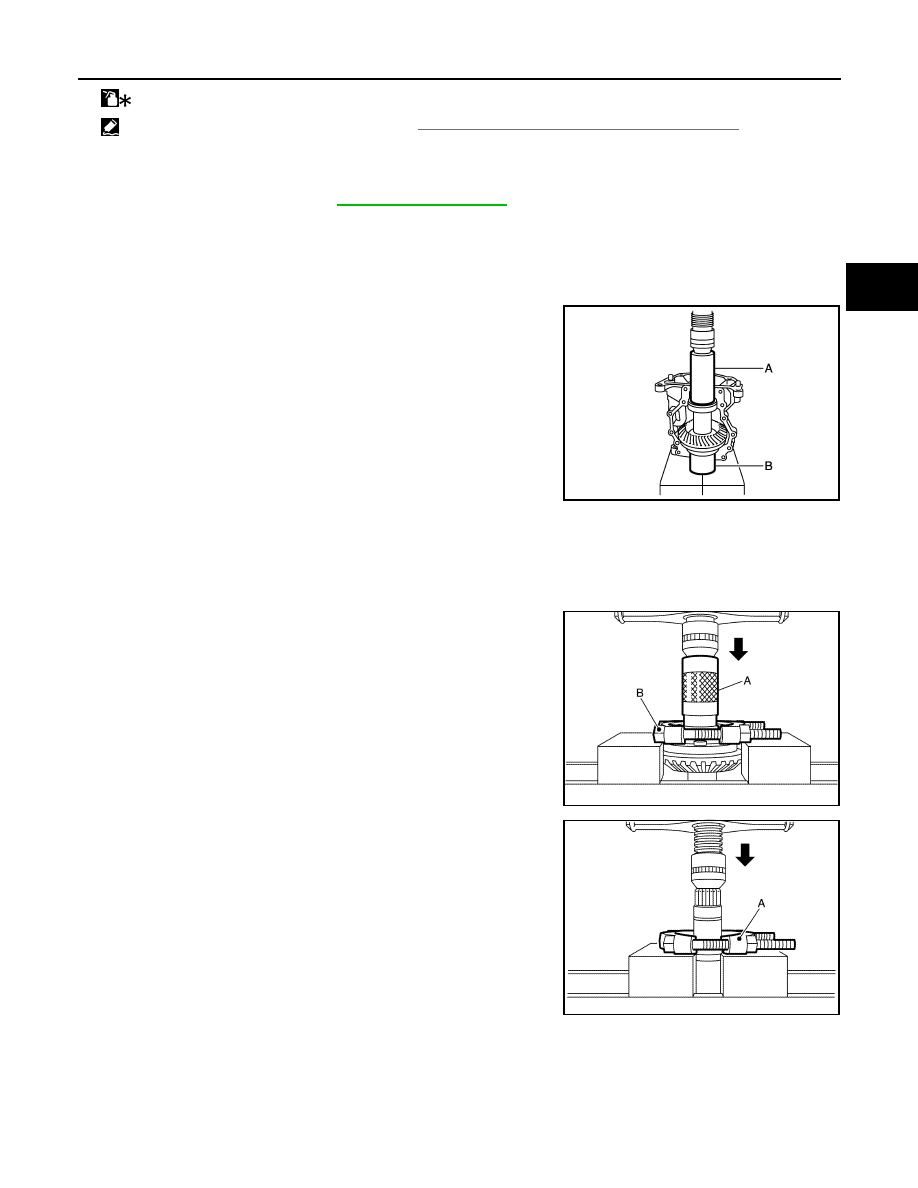

• Set the drifts (A and B) to right and left spacers individually.

Compress ring gear shaft assembly with ring gear bearing to

remove ring gear shaft assembly from transfer case.

CAUTION:

• The drift shall be placed on the center of the spacers.

• The pressure shall be as low as to remove ring gear

shaft assembly from transfer case. The maximum pres-

sure shall be 10 kN (1 ton, 1.0 Imp ton).

• If the adjusting shims and spacers are installed by tap-

ping, the transfer case may be damaged. Avoid tapping.

4. Remove spacer (right and left) from ring gear shaft assembly.

5. Remove ring gear bearing adjusting shim (right and left) from ring gear shaft assembly.

6. Remove outer races of ring gear bearing (right and left) from ring gear shaft assembly.

7. Remove inner race of ring gear bearing (right) from ring gear

shaft with the drift (A) and the replacer (B).

8. Remove inner race of ring gear bearing (left) from ring gear shaft

with the replacer (A) (Commercial service tool).

9. Remove the ring gear mounting bolts.

: Apply anti-corrosive oil.

: Apply Genuine Silicone RTV or equivalent. Refer to

GI-22, "Recommended Chemical Products and Sealants"

.

A

: Drift (Commercial service tool)

B

: Drift (Commercial service tool)

A

: Drift [SST: ST33200000 (J-26082)]

B

: Replacer (Commercial service tool)

JSDIA1106ZZ

JSDIA2165ZZ

JSDIA2166ZZ