Nissan Juke F15. Manual - part 131

C1155 BRAKE FLUID LEVEL SWITCH

BRC-115

< DTC/CIRCUIT DIAGNOSIS >

[WITH VDC]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

N

O

P

6. Check the combination meter harness connector for disconnection or looseness.

7. Check the combination meter pin terminals for damage or loose connection with harness connector.

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> Repair / replace harness, connector, or terminal, and GO TO 8.

8.

PERFORM SELF-DIAGNOSIS (4)

With CONSULT

1. Connect brake fluid level switch harness connector.

2. Connect combinetion meter harness connector.

3. Erase self-diagnosis result for “ABS”.

4. Turn the ignition switch OFF

→ ON → OFF.

NOTE:

Wait at least 10 seconds after turning ignition switch OFF or ON.

5. Start the engine.

NOTE:

Wait at least 10 seconds after start the engine.

6. Perform self-diagnosis for “ABS”.

Is DTC “C1155” detected?

YES

>> GO TO 9.

NO

>> INSPECTION END

9.

CHECK BRAKE FLUID LEVEL SWITCH CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect brake fluid level switch harness connector.

3. Disconnect combination meter harness connector.

4. Check the continuity between brake fluid level switch harness connector and combination meter harness

connector.

5. Check the continuity between brake fluid level switch harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 10.

NO

>> Repair / replace harness or connector, and GO TO 10.

10.

CHECK BRAKE FLUID LEVEL SWITCH GROUND CIRCUIT

Check the continuity between brake fluid level switch harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 11.

NO

>> Repair / replace harness or connector, and GO TO 11.

11.

CHECK COMBINATION METER

1. Connect brake fluid level switch harness connector.

2. Connect combinetion meter harness connector.

3. Check the combination meter. Refer to

MWI-21, "On Board Diagnosis Function"

.

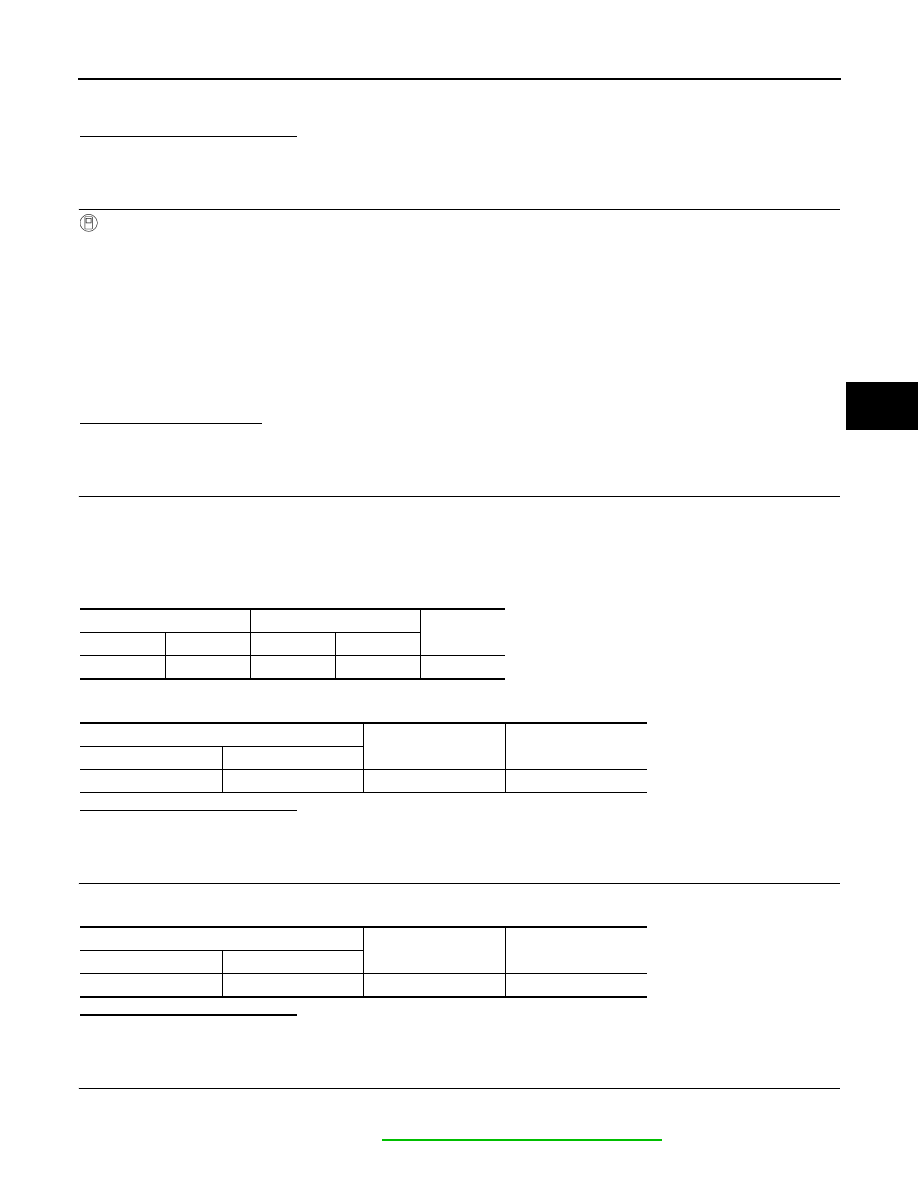

Brake fluid level switch

Combination meter

Continuity

Connector

Terminal

Connector

Terminal

E37

1

M34

11

Existed

Brake fluid level switch

—

Continuity

Connector

Terminal

E37

1

Ground

Not existed

Brake fluid level switch

—

Continuity

Connector

Terminal

E37

2

Ground

Existed