Content .. 1183 1184 1185 1186 ..

Nissan Juke F15. Manual - part 1185

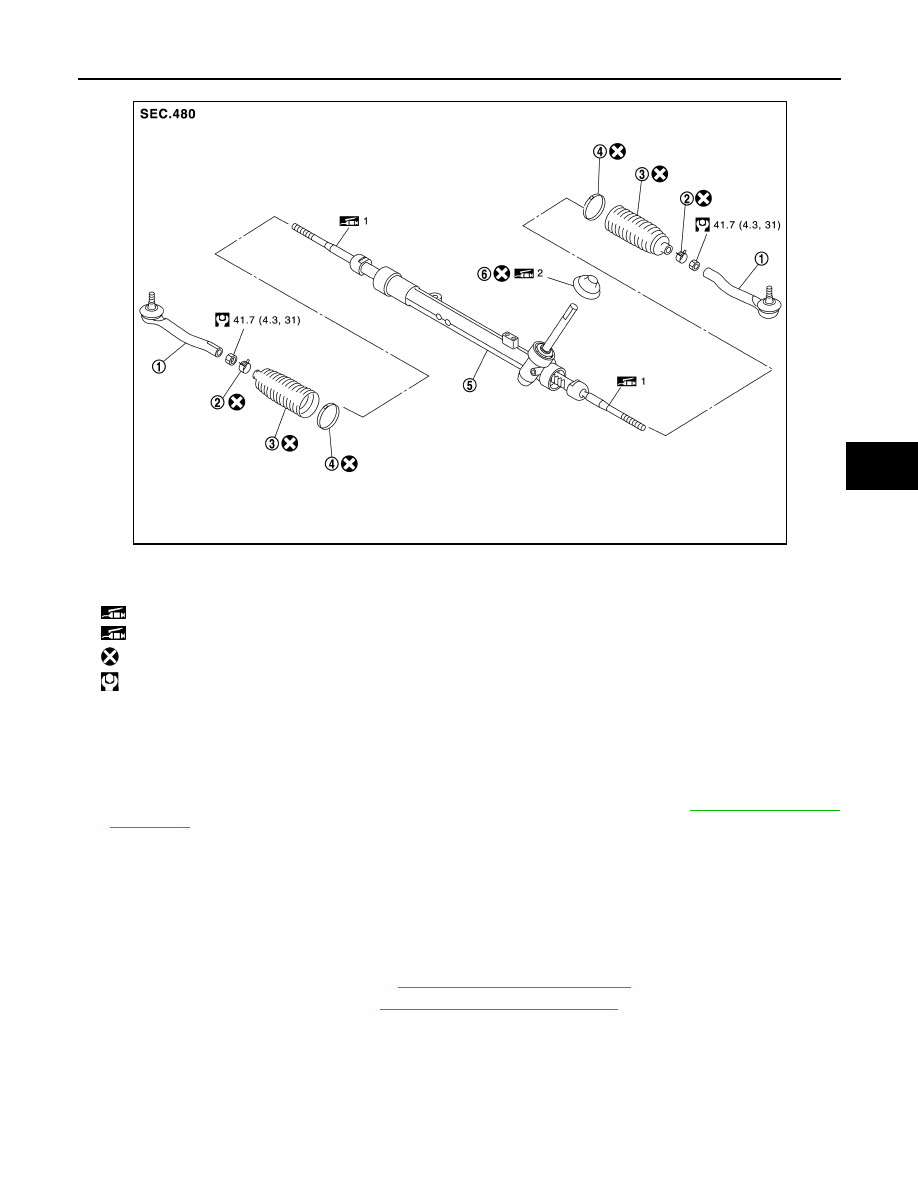

STEERING GEAR AND LINKAGE

ST-17

< REMOVAL AND INSTALLATION >

C

D

E

F

H

I

J

K

L

M

A

B

ST

N

O

P

Removal and Installation

INFOID:0000000012200348

REMOVAL

1. Set vehicle to the straight-ahead position.

2. Remove intermediate shaft mounting bolt (steering gear assembly side). Refer to

.

CAUTION:

• Spiral cable may be cut if steering wheel turns while separating steering column assembly and

steering gear assembly. Always fix the steering wheel using string to avoid turning.

• Place a matching mark on both intermediate shaft and steering gear assembly before removing

intermediate shaft.

• When removing intermediate shaft, never insert a tool, such as a screwdriver, into the yoke

groove to pull out the intermediate shaft. In case of the violation of the above, replace intermedi-

ate shaft with a new one.

3. Remove dash seal from vehicle. Refer to

ST-14, "Removal and Installation"

.

4. Remove tires with power tool. Refer to

WT-39, "Removal and Installation"

.

1.

Outer socket

2.

Boot clamp (small diameter)

3.

Boot

4.

Boot clamp (large diameter)

5.

Gear housing assembly

6.

Dust cover

1: Apply Genuine Lithium Soap, Autorex A (manufactured by Kyodo yushi) or equivalent.

2: Apply Genuine Lithium Soap, Wanlouver No.2 (manufactured by Kyodo yushi) or equivalent.

: Always replace after every disassembly.

: N·m (kg-m, ft-lb)

JPGIA0145GB