Content .. 1184 1185 1186 1187 ..

Nissan Juke F15. Manual - part 1186

SERVICE DATA AND SPECIFICATIONS (SDS)

ST-21

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D

E

F

H

I

J

K

L

M

A

B

ST

N

O

P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

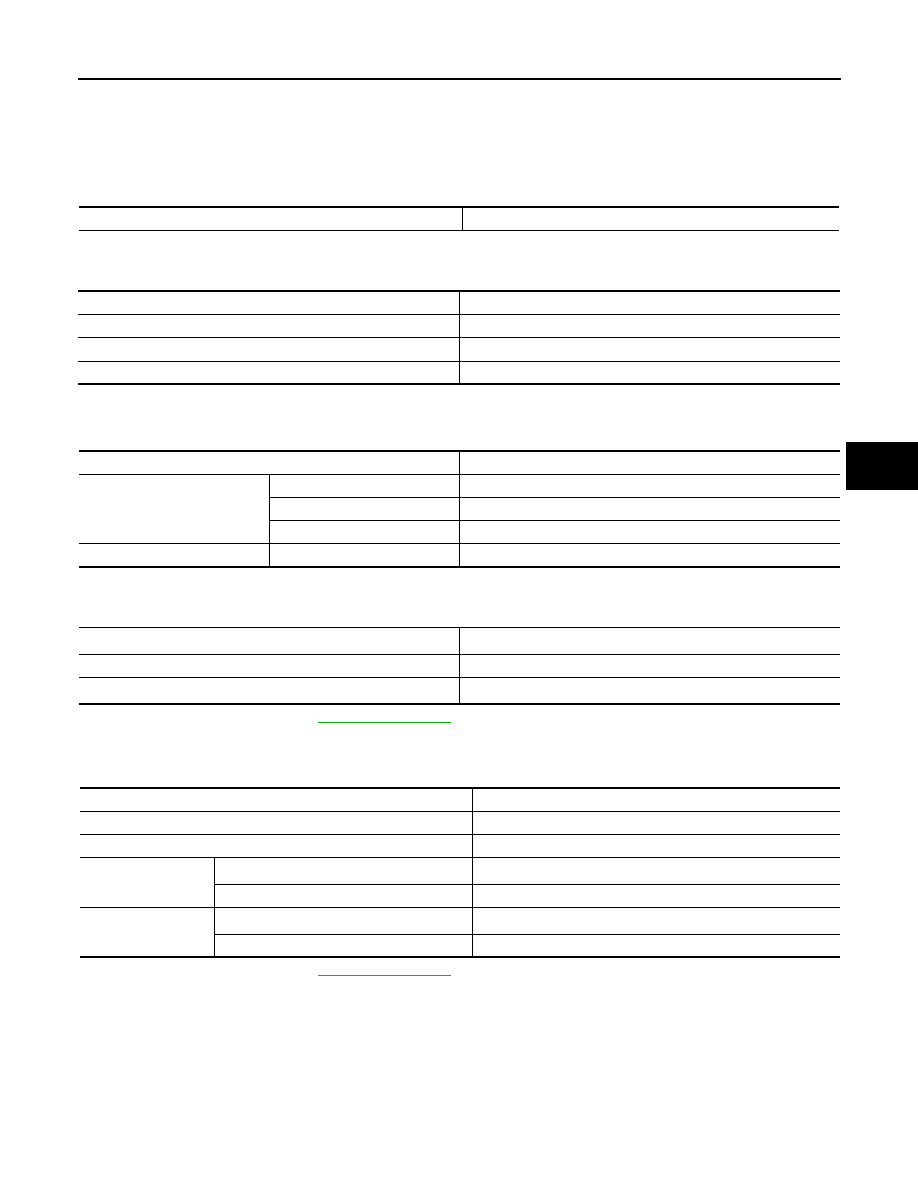

General Specifications

INFOID:0000000012200351

Steering Wheel

INFOID:0000000012200352

Steering Angle

INFOID:0000000012200353

Unit: Degree minute (Decimal degree)

Steering Column

INFOID:0000000012200354

*: For measuring position, refer to

Steering Gear and Linkage

INFOID:0000000012200355

*: For measuring position, refer to

Steering gear model

R25N

Item

Standard

Steering wheel axial end play

0 mm (0 in)

Steering wheel play on the outer circumference

0 - 35 mm (0 - 1.38 in)

Steering wheel turning force

36 N (3.7 kg-f, 8.09 lb-f) or less

Item

Standard

Inner wheel

Minimum

33

° 00′ (33.0°)

Nominal

36

° 00′ (36.0°)

Maximum

37

° 00′ (37.0°)

Outer wheel

Nominal

31

° 00′ (31.0°)

Tilt operating range

*

40.0 mm (1.575 in)

Rotating torque

0 – 2.1 N·m (0 – 0.21 kg-m, 0 – 2 in-lb)

Steering column length

*

438.5 – 440.5 mm (17.26 – 17.34 in)

Item

Standard

Rack stroke neutral position

68 mm (2.68 in)

Inner socket length

83.5 mm (3.287 in)

Outer socket ball joint

Spring balance measurement

*

6.0 – 58 N (0.61 – 5.9 kg-f, 1.35 – 13.03 lb-f)

Axial end play

0.5 mm (0.020 in) or less

Inner socket ball joint

Spring balance measurement

*

4.3 – 43.1 N (0.44 – 4.39 kg-f, 0.97 – 9.68 lb-f)

Axial end play

0.2 mm (0.008 in) or less