Content .. 1096 1097 1098 1099 ..

Nissan Juke F15. Manual - part 1098

COIL SPRING

RSU-13

< REMOVAL AND INSTALLATION >

[2WD]

C

D

F

G

H

I

J

K

L

M

A

B

RSU

N

O

P

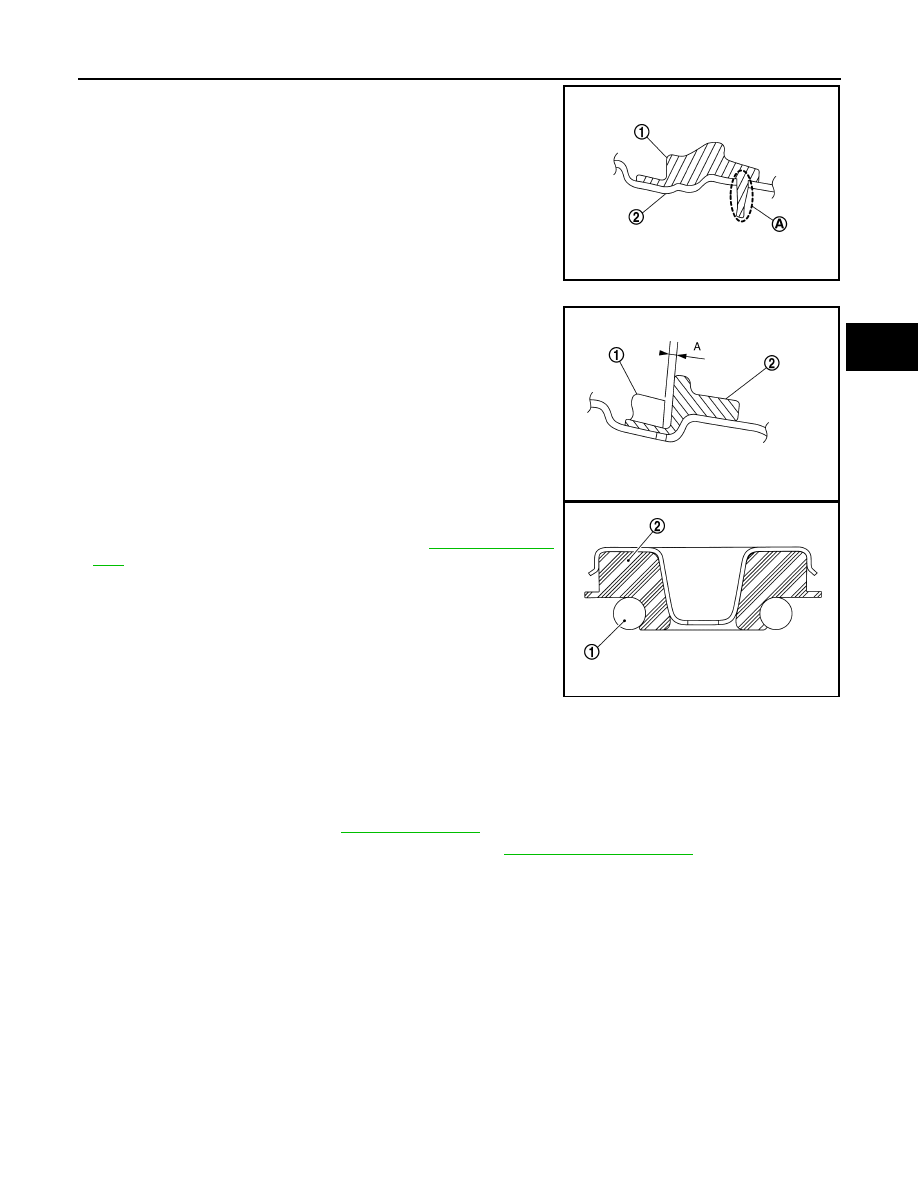

• Match up lower rubber seat (1) indentions and rear suspension

beam (2) grooves (A) and attach.

• Securely install coil spring (1) with the lower end of the major diam-

eter aligned with the steps of lower rubber seat (2).

• Install coil spring (1) by aligning upper end of coil spring with upper

seat (2) in to the protrusion of body side as shown in the figure.

• Perform inspection after installation. Refer to

Inspection

INFOID:0000000012200399

INSPECTION AFTER REMOVAL

Check rubber seat and coil spring for deformation, crack, and damage. Replace it if necessary.

INSPECTION AFTER INSTALLATION

1. Check wheel alignment. Refer to

2. Adjust neutral position of steering angle sensor. Refer to

.

JSEIA0900ZZ

Dimension (A)

: 5 mm (0.20 in) or less

JSEIA0899ZZ

JSEIA0901ZZ