Content .. 1094 1095 1096 1097 ..

Nissan Juke F15. Manual - part 1096

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

RSU-5

< SYMPTOM DIAGNOSIS >

[2WD]

C

D

F

G

H

I

J

K

L

M

A

B

RSU

N

O

P

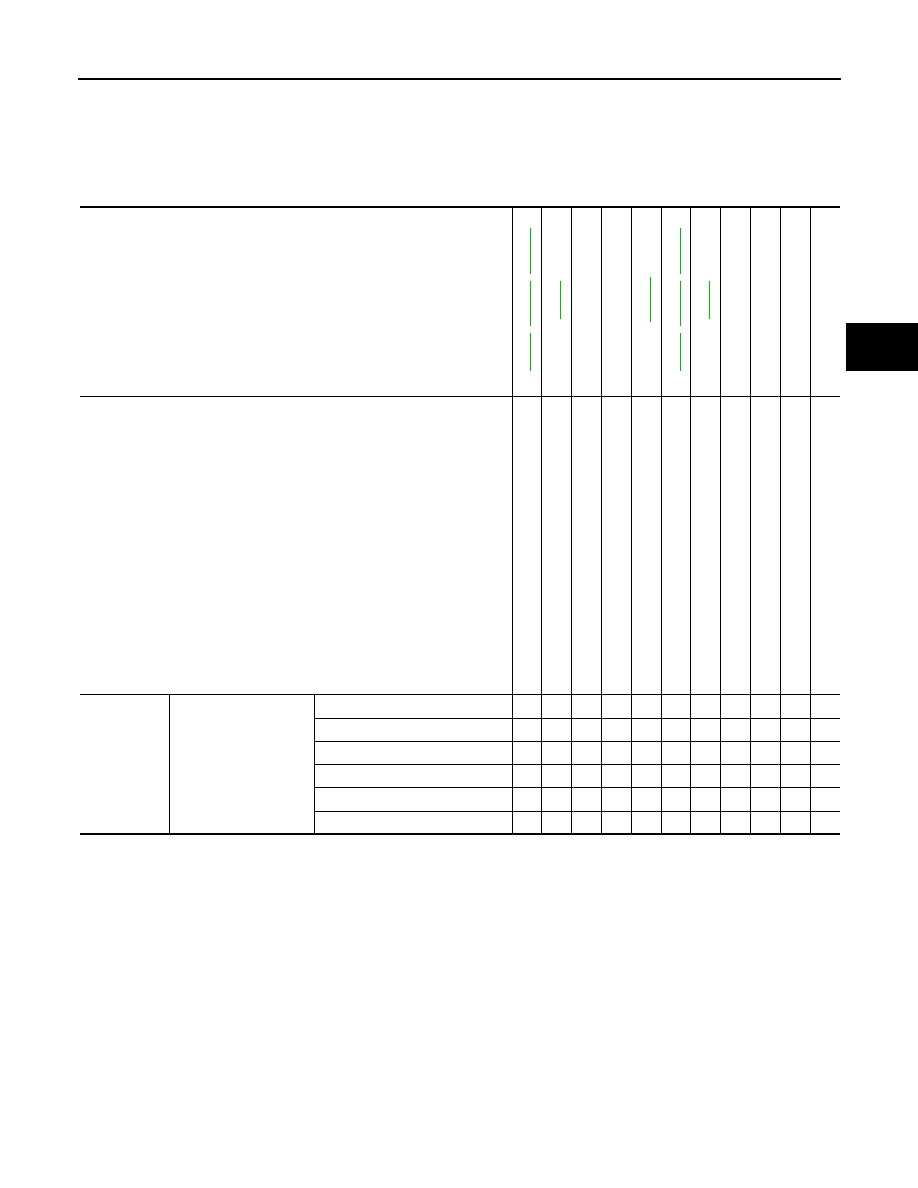

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

INFOID:0000000012200390

Use chart below to find the cause of the symptom. If necessary, repair or replace these parts.

×: Applicable

Reference

,

,

—

—

,

,

NVH

in

RAX and RSU sections

NVH in WT section

NVH in WT section

NVH in BR section

Possible cause and SUSPECTED PARTS

Imp

rop

er i

ns

ta

lla

tio

n,

lo

os

en

es

s

Sh

oc

k

ab

so

rbe

r de

form

a

tio

n,

dam

a

ge

or d

ef

lec

tion

Bu

sh

in

g o

r m

ou

nti

ng

de

teri

ora

tio

n

Part

s interf

erence

S

p

rin

g f

ati

gu

e

Su

sp

en

si

on

lo

os

en

es

s

In

co

rrec

t wh

ee

l a

lig

nm

en

t

REAR A

XLE

AND REAR SUSPE

NSION

TI

RE

ROAD WHEE

L

BRAKE

Symptom

REAR SUSPENSION

Noise

×

×

×

×

×

×

×

×

×

×

Shake

×

×

×

×

×

×

×

×

×

Vibration

×

×

×

×

×

×

×

Shimmy

×

×

×

×

×

×

×

×

×

Judder

×

×

×

×

×

×

×

Poor quality ride or handling

×

×

×

×

×

×

×

×

×