Content .. 1080 1081 1082 1083 ..

Nissan Juke F15. Manual - part 1082

RAX-20

< REMOVAL AND INSTALLATION >

[AWD]

REAR DRIVE SHAFT

CAUTION:

• Never damage the suspension arm with a jack.

• Check the stable condition when using a jack.

9. Remove stabilizer link. Refer to

RSU-35, "Removal and Installation"

10. Remove shock absorber from suspension arm. Refer to

RSU-24, "Removal and Installation"

.

11. Remove upper link from suspension arm. Refer to

RSU-33, "Removal and Installation"

.

12. Remove lower link from suspension arm. Refer to

RSU-31, "Removal and Installation"

13. Remove drive shaft from final drive assembly.

CAUTION:

Confirm that the circular clip is attached to the drive shaft.

14. Perform inspection after removal. Refer to

INSTALLATION

Note the following, and install in the reverse order of removal.

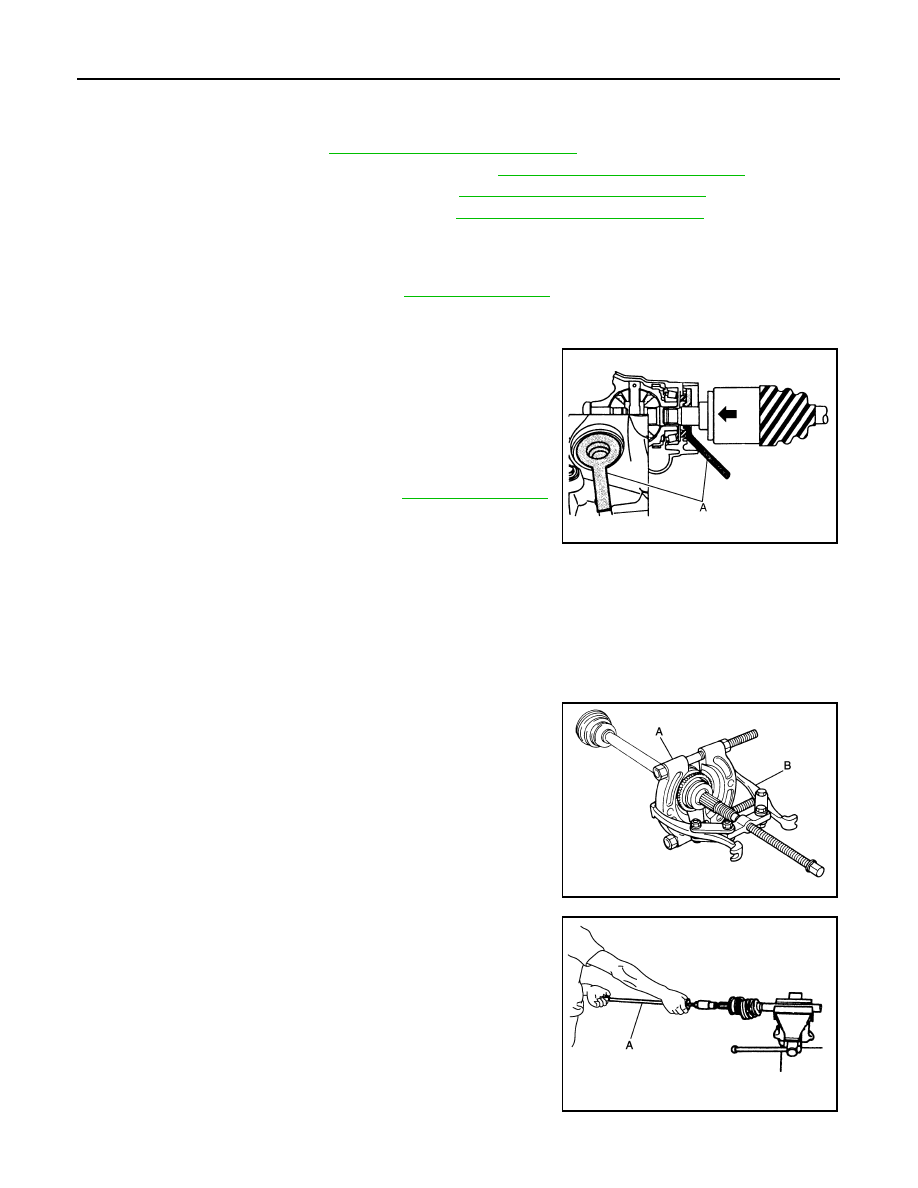

• Place the protector (A) [SST:KV38107900 ( — )] onto final drive

assembly to prevent damage to the oil seal while inserting drive

shaft. Slide drive shaft sliding joint and tap with a hammer to install

securely.

CAUTION:

Check that circular clip is completely engaged.

• Perform final tightening of bolts and nuts at suspension arm (rub-

ber bushing), under unladen conditions with tires on level ground.

• Perform inspection after installation. Refer to

.

WHEEL SIDE

WHEEL SIDE : Disassembly and Assembly

INFOID:0000000012196566

DISASSEMBLY

1. Fix shaft with a vise.

CAUTION:

Protect shaft using aluminum or copper plates when fixing with a vise.

2. If sensor rotor needs to be removed, use a bearing replacer (A)

and puller (B).

3. Remove boot bands. Then remove boot from joint sub-assem-

bly.

4. Screw drive shaft puller (A) (commercial service tool) into joint

sub-assembly screw part to a length of 30 mm (1.18 in) or more.

Support drive shaft with one hand and pull out joint sub-assem-

bly from shaft.

CAUTION:

• Align drive shaft puller and drive shaft and remove them

by pulling firmly and uniformly.

• If joint sub-assembly cannot be removed after five or

more unsuccessful attempts, replace shaft and joint sub

assembly as a set.

5. Remove circular clip from shaft.

6. Remove boot from shaft.

JPDIF0023ZZ

JPDIG0016ZZ

JPDIG0151ZZ