Nissan Juke F15. Manual - part 101

BR-64

< REMOVAL AND INSTALLATION >

REAR DISC BRAKE

BRAKE CALIPER ASSEMBLY : Removal and Installation

INFOID:0000000012200308

REMOVAL

WARNING:

Since dust covering the rear brake has an affect on human body, the dust must be removed with a

dust collector. Never splatter the dust with an air blow gun.

CAUTION:

• Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

out immediately and wash with water if it gets on a protect surface. For brake component parts,

never wash them with water.

• Never depress the brake pedal while removing the brake hose. If this is not complied with, brake

fluid may splash.

• Never drop removed parts.

• If the brake fluid or grease adheres to the disc rotor, quickly wipe it off.

1. Remove tires with power tool.

2. Fix the disc rotor using wheel nuts.

3. Drain brake fluid. Refer to

.

4. Separate brake hose from caliper assembly. Refer to

BR-32, "REAR : Removal and Installation"

.

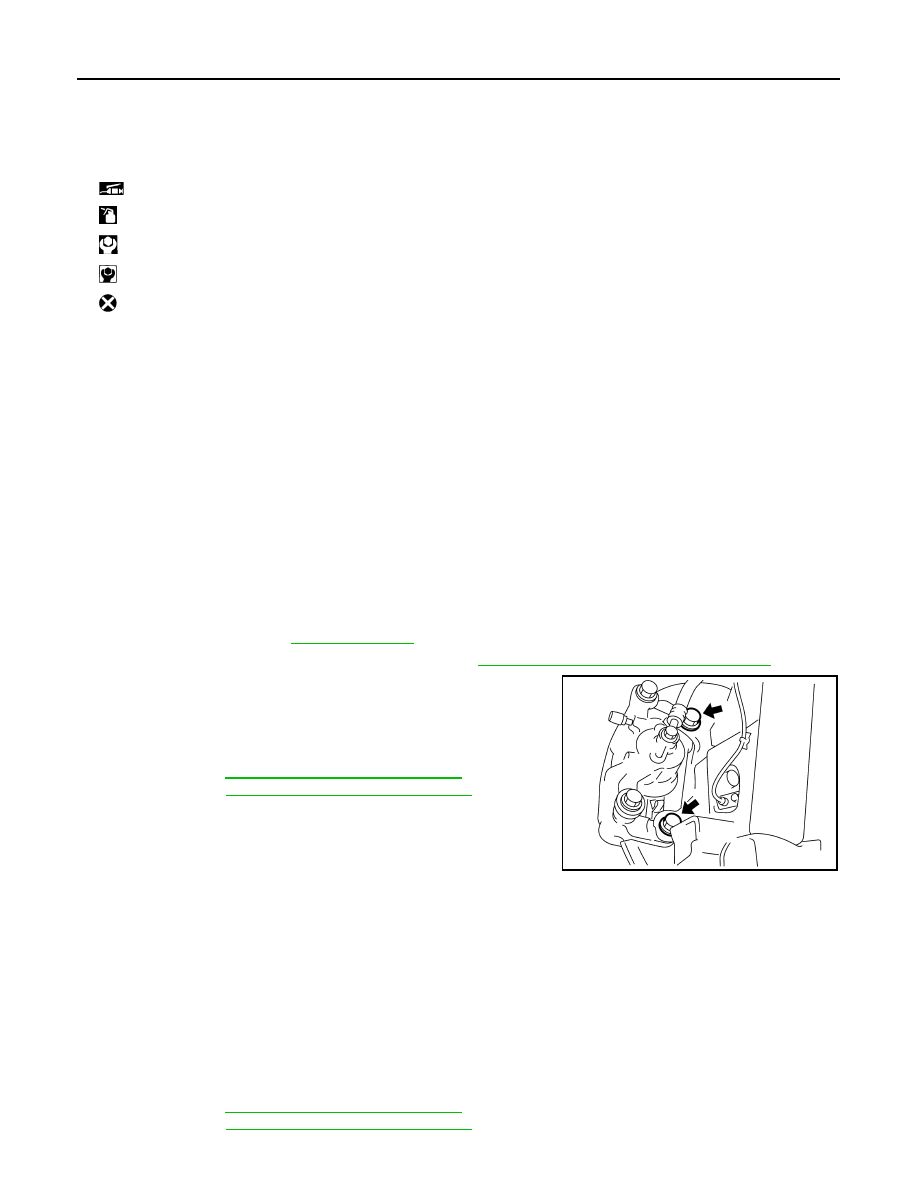

5. Remove torque member mounting bolts, and remove brake cali-

per assembly.

CAUTION:

Never drop brake pad and caliper assembly.

6. When removing disc rotor.

• 2WD: Refer to

RAX-7, "Removal and Installation"

.

• AWD: Refer to

RAX-16, "Removal and Installation"

.

INSTALLATION

WARNING:

Since dust covering the rear brake has an affect on human body, the dust must be removed with a

dust collector. Never splatter the dust with an air blow gun.

CAUTION:

• Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

out immediately and wash with water if it gets on a protect surface. For brake component parts,

never wash them with water.

• Never depress the brake pedal while removing the brake hose. If this is not complied with, brake

fluid may splash.

• If the brake fluid or grease adheres to the disc rotor, quickly wipe it off.

1. Install disc rotor.

• 2WD: Refer to

RAX-7, "Removal and Installation"

.

• AWD: Refer to

RAX-16, "Removal and Installation"

.

1.

Sliding pin bolt

2.

Bushing

3.

Cap

4.

Bleeder valve

5.

Cylinder body

6.

Piston seal

7.

Piston

8.

Piston boot

9.

Sliding pin boot

10. Torque member

: Apply rubber grease.

: Apply brake fluid.

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: Always replace after every disassembly.

JSFIA0495ZZ