содержание .. 786 787 788 789 ..

Nissan Tiida C11. Manual - part 788

FRONT DRIVE SHAFT

FAX-17

< DISASSEMBLY AND ASSEMBLY >

C

E

F

G

H

I

J

K

L

M

A

B

FAX

N

O

P

2.

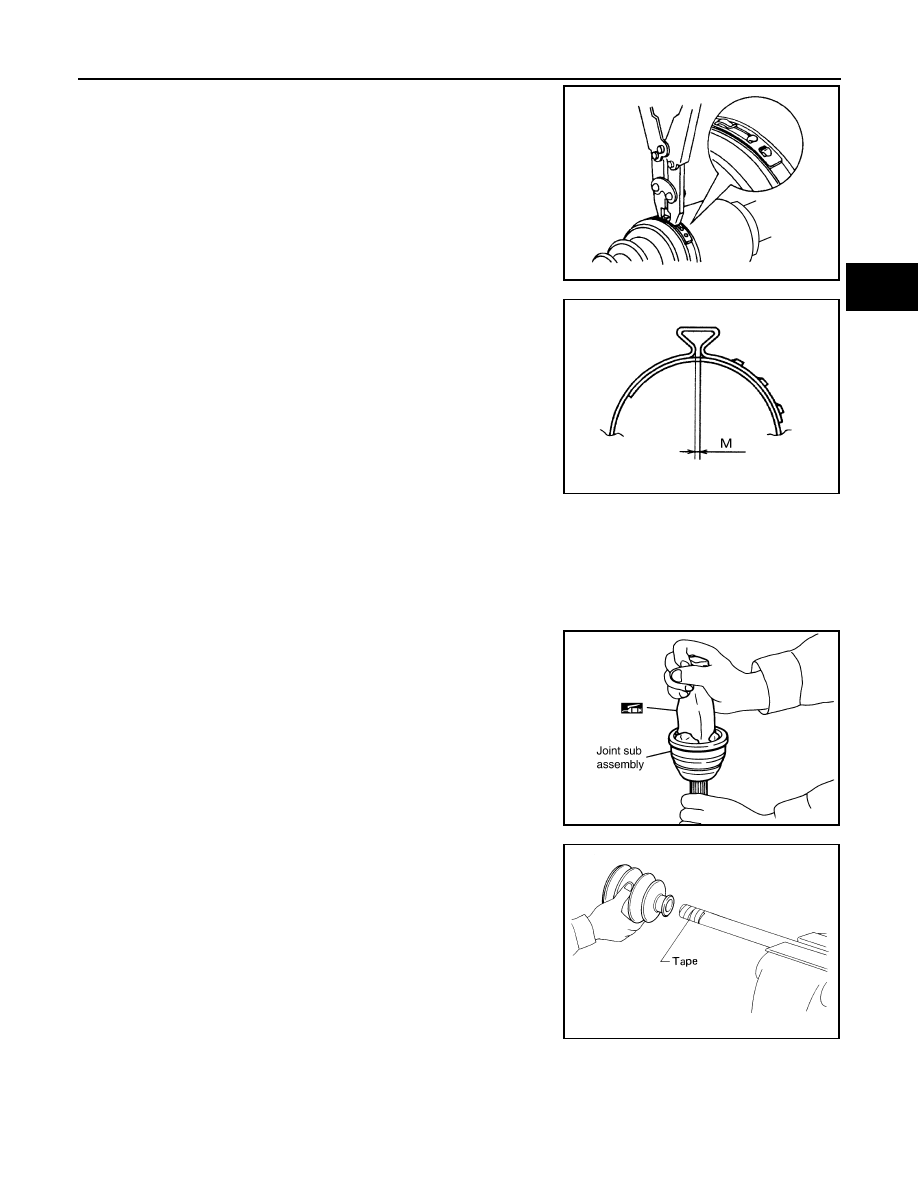

Pull and tighten the boot band using suitable tool until both

pawls of boot band are secured in the boot band grooves.

CAUTION:

Do not reuse boot band.

10. Install new small boot band securely using Tool.

CAUTION:

• Do not reuse boot band.

• Secure boot band so that dimension “M” meets specifica-

tion as shown.

11. Rotate the slide joint and confirm that the boot position is correct. If boot position is not correct, remove

the boot bands, reposition the boot and install new boot bands.

12. Install new dust shield to slide joint housing.

CAUTION:

Do not reuse dust shield.

Wheel Side

1.

Insert recommended grease (Genuine NISSAN Grease or

equivalent) into joint sub-assembly serration hole until grease

begins to ooze from ball groove and serration hole. After insert-

ing grease, use a shop cloth to wipe off old grease that has

oozed out.

2.

Cover serrated part of shaft with tape. Install new boot band and

new boot to shaft.

CAUTION:

Do not reuse boot or boot band.

3.

Remove protective tape wound around serrated part of shaft.

RAC1133D

Tool number

: KV40107300 (

—

)

Dimension “M”

: 1.0 – 4.0 mm (0.039 – 0.157 in)

DSF0047D

SDIA1127E

SFA800