содержание .. 785 786 787 788 ..

Nissan Tiida C11. Manual - part 787

FRONT DRIVE SHAFT

FAX-13

< REMOVAL AND INSTALLATION >

C

E

F

G

H

I

J

K

L

M

A

B

FAX

N

O

P

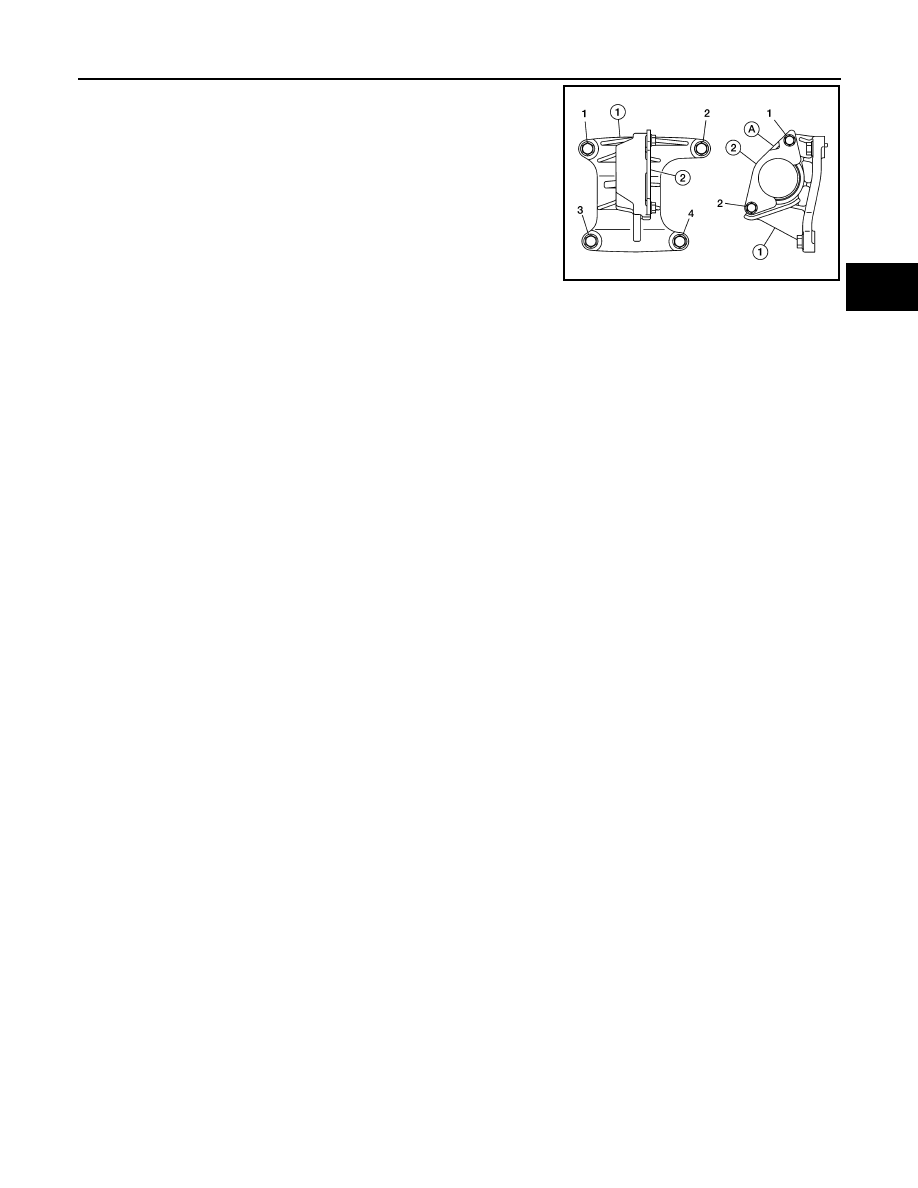

• When installing the support bearing bracket (1), note the following:

a. Tighten the support bearing bracket bolts in two stages, in the

order as shown.

b. Install the plate (2) with the notch (A) upward. Tighten the plate

bolts in two stages, in the order as shown.

WDIA0361E