содержание .. 700 701 702 703 ..

Nissan Tiida C11. Manual - part 702

EM-160

< ON-VEHICLE REPAIR >

[MR18DE]

EXHAUST MANIFOLD

5.

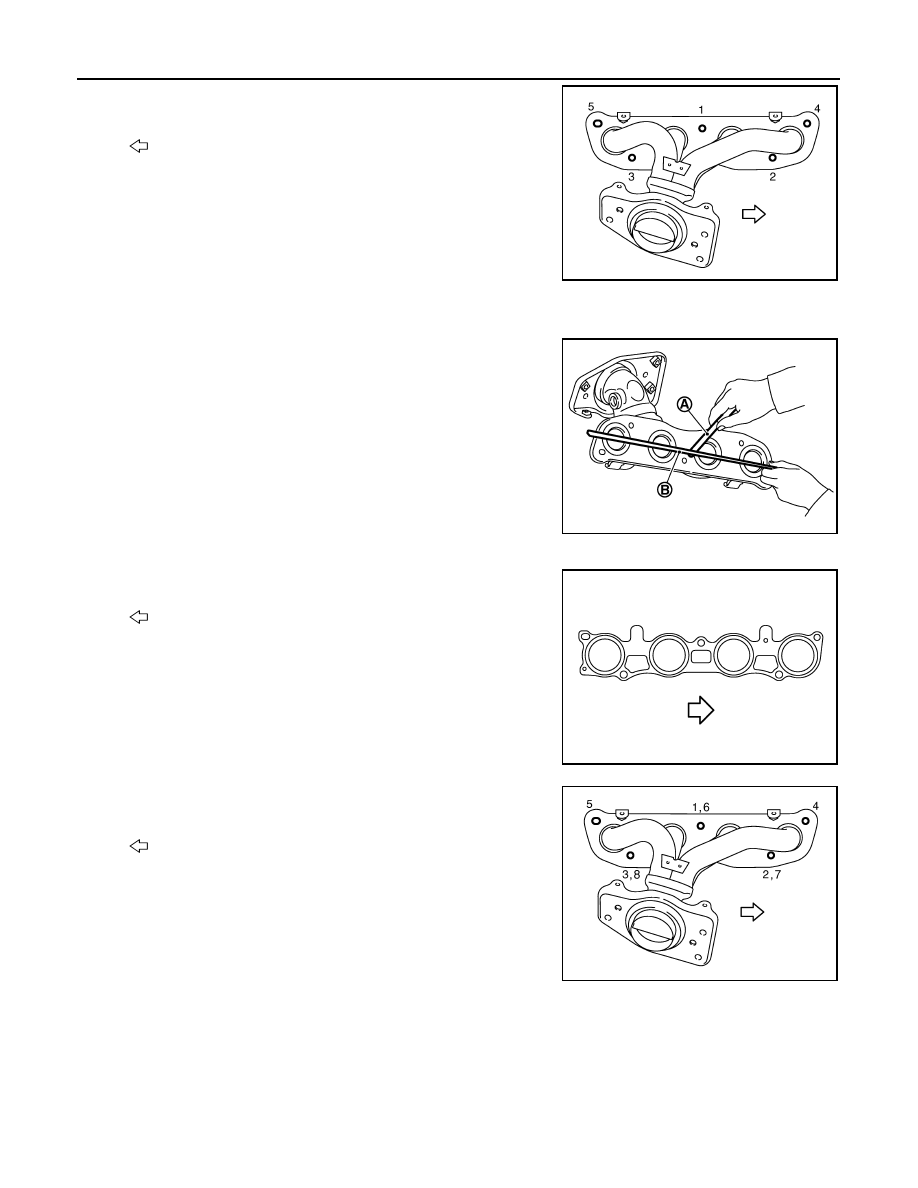

Loosen nuts in reverse order as shown and remove exhaust

manifold.

CAUTION:

Cover engine openings to avoid entry of foreign materials.

INSPECTION AFTER REMOVAL

Surface Distortion

• Using straightedge (B) and feeler gauge (A), check the surface dis-

tortion of exhaust manifold mating surface in each exhaust port

and entire part.

• If it exceeds the limit, replace exhaust manifold.

INSTALLATION

1.

Install exhaust manifold gasket to cylinder head as shown.

2.

Tighten exhaust manifold nuts to specification in two stages in

the numerical order as shown.

: Engine front

PBIC3529J

Limit:

Each exhaust port

: 0.3 mm (0.012 in)

Entire part

: 0.7 mm (0.028 in)

PBIC3530J

: Engine front

PBIC3943E

: Engine front

WBIA0854E