содержание .. 695 696 697 698 ..

Nissan Tiida C11. Manual - part 697

EM-140

< PREPARATION >

[MR18DE]

PREPARATION

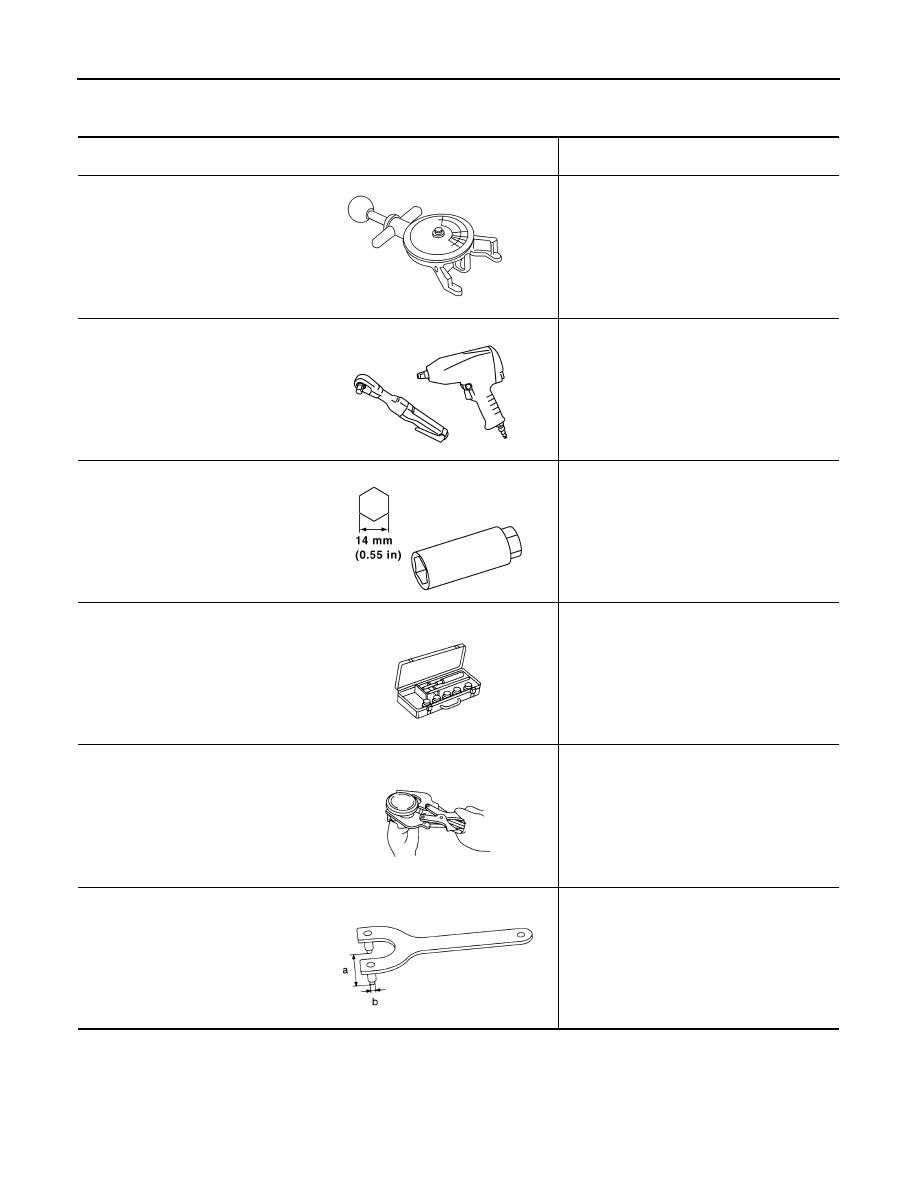

Commercial Service Tool

INFOID:0000000001337773

(Kent-Moore No.)

Tool name

Description

(BT-3373-F)

Belt tension gauge

Checking drive belt tension

Power tool

Loosening bolts and nuts

Spark plug wrench

Removing and installing spark plug

Valve seat cutter set

Finishing valve seat dimensions

Piston ring expander

Removing and installing piston ring

KV10109300

(

—

)

Pulley holder

Removing and installing crankshaft pulley

AMA126

PBIC0190E

PBIC2982E

NT048

NT030

NT628