содержание .. 670 671 672 673 ..

Nissan Tiida C11. Manual - part 672

EM-40

< ON-VEHICLE REPAIR >

[HR16DE]

OIL PAN (LOWER)

OIL PAN (LOWER)

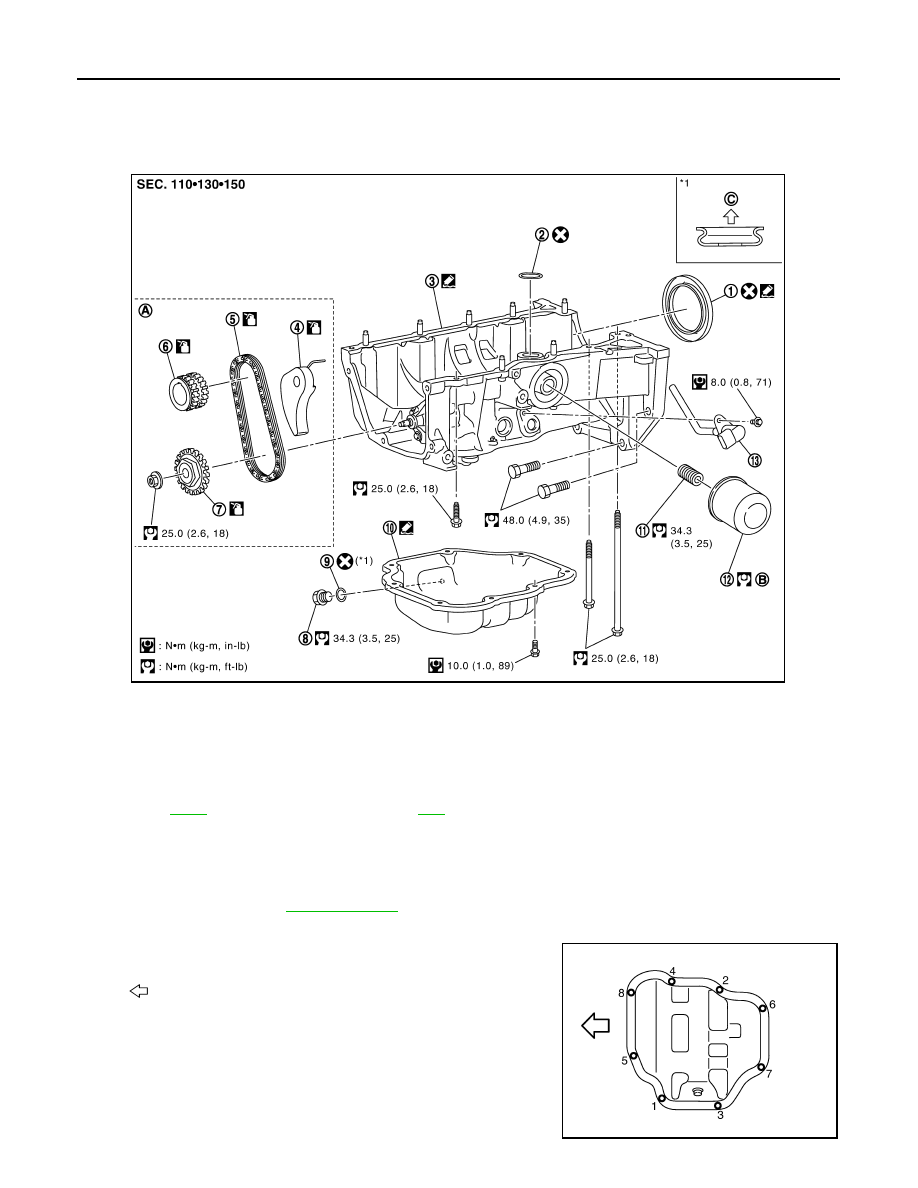

Exploded View

INFOID:0000000001381406

Removal and Installation

INFOID:0000000001381407

REMOVAL

1.

Drain engine oil. Refer to

.

2.

Remove the oil pan (lower) with the following procedure.

a.

Loosen bolts in the reverse of the order shown.

b.

Insert the seal cutter [SST: KV10111100] between oil pan

(upper) and oil pan (lower).

CAUTION:

• Be careful not to damage the mating surface.

• A more adhesive liquid gasket is applied compared to pre-

vious types when shipped, so it should not be forced off

using a flat- bladed screwdriver, etc.

1.

Rear oil seal

2.

O-ring

3.

Oil pan (upper)

4.

Chain tensioner

5.

Oil pump drive chain

6.

Crankshaft sprocket

7.

Oil pump sprocket

8.

Oil pan drain plug

9.

Washer

10.

Oil pan (lower)

11.

Oil filter stud bolt

12.

Oil filter

13.

Oil level sensor

A.

Refer to

B.

Refer to

C.

Oil pan side

JPBIA0553GB

: Engine front

PBIC4345E