содержание .. 639 640 641 642 ..

Nissan Tiida C11. Manual - part 641

EC-1214

< COMPONENT DIAGNOSIS >

[K9K]

STOP LAMP SWITCH

STOP LAMP SWITCH

Description

INFOID:0000000001162692

Brake switch signal is applied to the ECM through the stop lamp switch when the brake pedal is depressed.

This signal is used mainly to decrease the engine speed when the vehicle is driving.

Component Function Check

INFOID:0000000001162693

1.

CHECK BRAKE SWITCH FUNCTION

1.

Turn ignition switch ON.

2.

Check the voltage between ECM harness connector and ground.

Is the inspection result normal?

YES

>> INSPECTION END.

NO

>> Go to

EC-1214, "Diagnosis Procedure"

Diagnosis Procedure

INFOID:0000000001162694

1.

CHECK BRAKE SWITCH POWER SUPPLY CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect stop lamp switch harness connector.

3.

Turn ignition switch ON.

4.

Check the voltage between stop lamp switch harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> GO TO 2.

2.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors M69, E7 (LHD models)

• Harness connectors M25, M201 (RHD models)

• 10A fuse (No. 7)

• Harness for open or short between fuse and stop lamp switch

>> Repair open circuit or short to ground or short to power in harness or connectors.

3.

CHECK BRAKE SWITCH INPUT SIGNAL CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check the continuity between stop lamp switch harness connector and ECM harness connector.

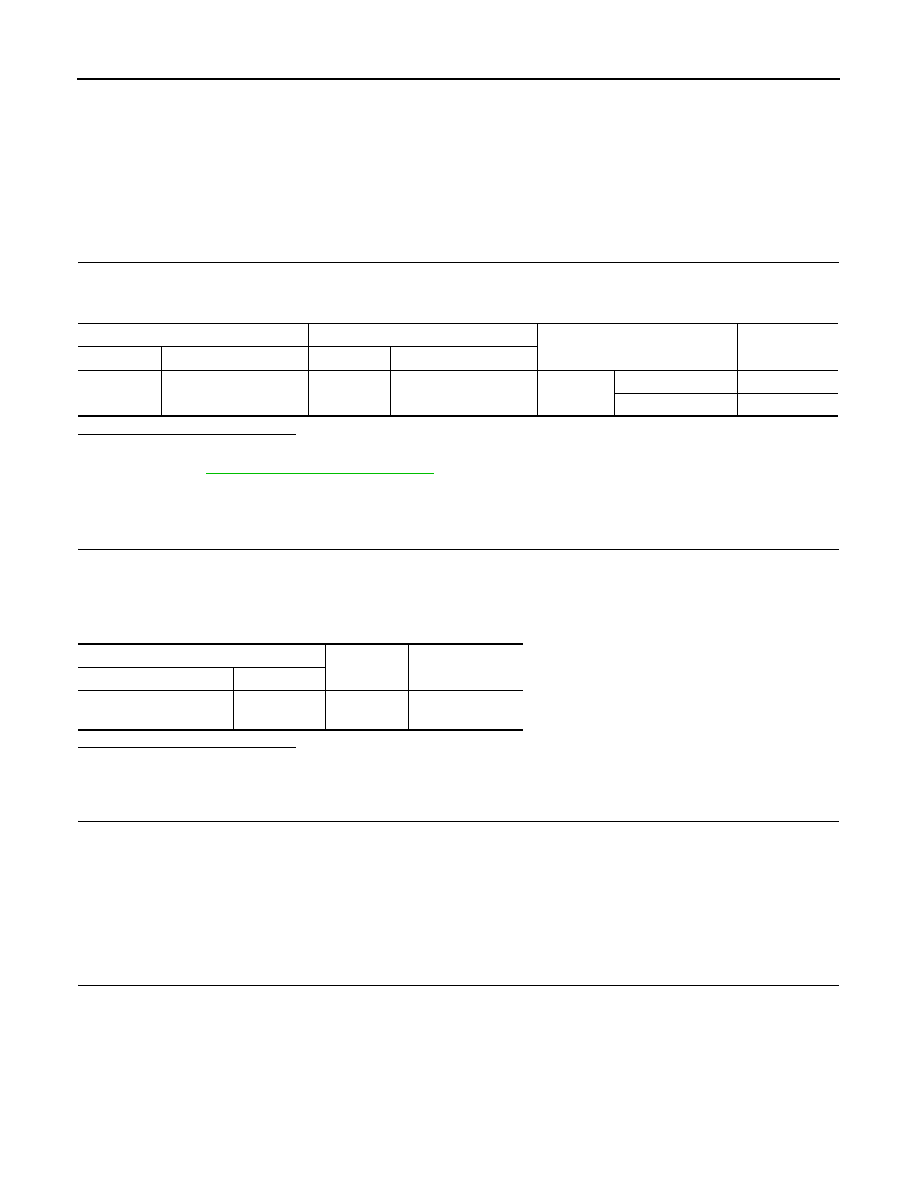

+

–

Condition

Voltage

Connector

Terminal

Connector

Terminal

E16

115

(Brake switch signal)

E16

128

Brake ped-

al

Fully released

0V

Slightly depressed

Battery voltage

Stop lamp switch

Ground

Voltage

Connector

Terminal

E13 (LHD models)

M203 (RHD models)

1

Ground

Battery voltage