содержание .. 622 623 624 625 ..

Nissan Tiida C11. Manual - part 624

EC-1146

< COMPONENT DIAGNOSIS >

[K9K]

P0225 APP SENSOR

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> Replace accelerator pedal position sensor.

9.

CHECK INTERMITTENT INCIDENT

GI-55, "Intermittent Incident"

>> INSPECTION END

Component Inspection

INFOID:0000000001162607

1.

CHECK ACCELERATOR PEDAL POSITION SENSOR

1.

Turn ignition switch OFF.

2.

Disconnect accelerator pedal position sensor harness connector.

3.

Check resistance between accelerator pedal position sensor as follows.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace accelerator pedal position sensor.

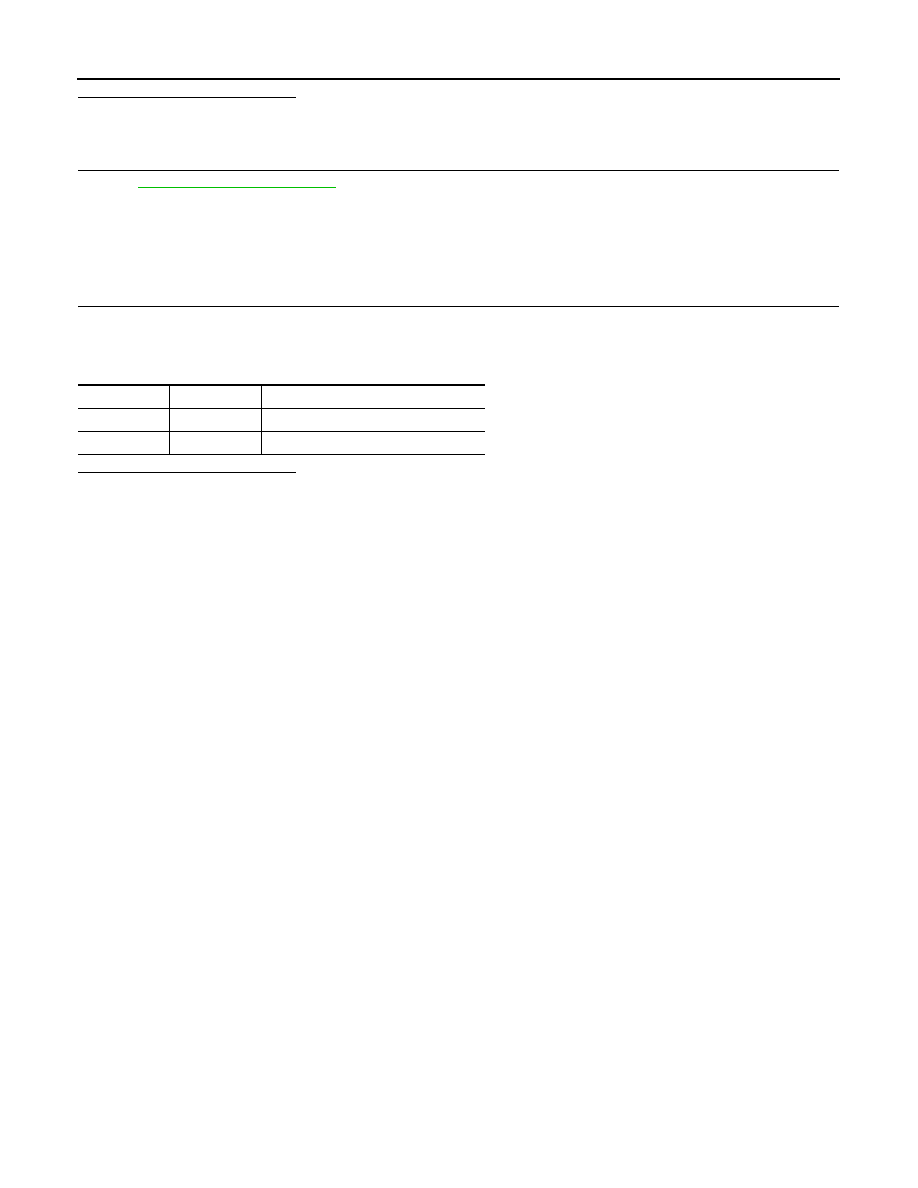

Sensor

Terminals

Resistance

1

2 and 4

1.7

±

0.9 K

Ω

2

1 and 5

2.85

±

2.05 K

Ω