содержание .. 488 489 490 491 ..

Nissan Tiida C11. Manual - part 490

EC-610

< COMPONENT DIAGNOSIS >

[HR16DE (WITHOUT EURO-OBD)]

HO2S1

2.

Disconnect heated oxygen sensor 1 harness connector.

3.

Disconnect ECM harness connector.

4.

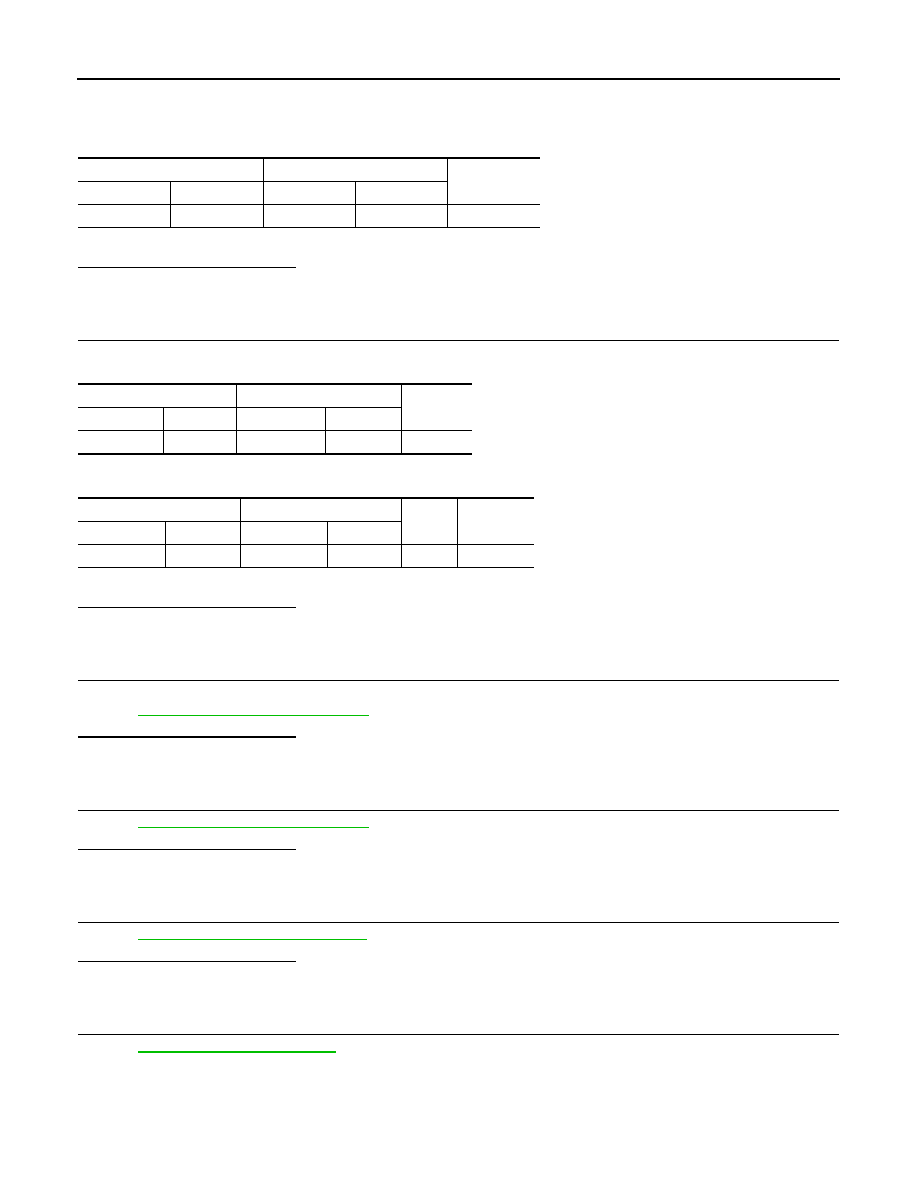

Check harness continuity between HO2S1 harness connector and ECM harness connector.

5.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

6.

CHECK HEATED OXYGEN SENSOR 1 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1.

Check the continuity between HO2S1 harness connector and ECM harness connector.

2.

Check the continuity between HO2S1 harness connector or ECM harness connector and ground.

3.

Also check harness for short to power.

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

7.

CHECK MASS AIR FLOW SENSOR

Check mass air flow sensor.

Refer to

EC-489, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> Replace mass air flow sensor.

8.

CHECK PCV VALVE

EC-631, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> Repair or replace PCV valve.

9.

CHECK HEATED OXYGEN SENSOR 1

Perform

EC-611, "Component Inspection"

.

Is the inspection result normal?

YES

>> GO TO 10.

NO

>> Replace heated oxygen sensor 1.

10.

CHECK INTERMITTENT INCIDENT

GI-55, "Intermittent Incident"

>> INSPECTION END

HO2S1

ECM

Continuity

Connector

Terminal

Connector

Terminal

F30

1

F8

56

existed

HO2S1

ECM

Continuity

Connector

Terminal

Connector

Terminal

F30

1

F8

56

Existed

HO2S1

ECM

Ground

Continuity

Connector

Terminal

Connector

Terminal

F30

4

F8

49

Ground

Not existed