содержание .. 417 418 419 420 ..

Nissan Tiida C11. Manual - part 419

EC-326

< COMPONENT DIAGNOSIS >

[HR16DE (WITH EURO-OBD)]

REFRIGERANT PRESSURE SENSOR

REFRIGERANT PRESSURE SENSOR

Description

INFOID:0000000001671117

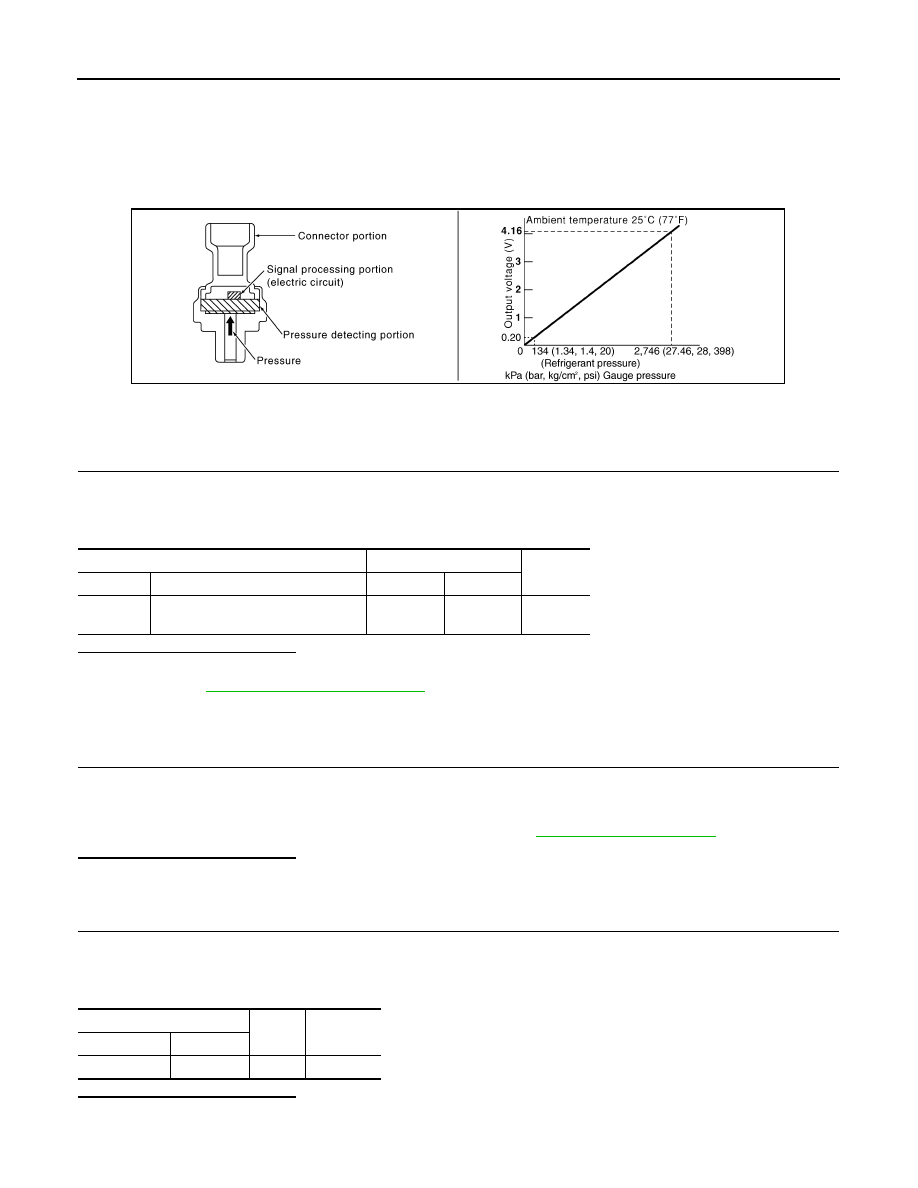

The refrigerant pressure sensor is installed at the condenser of the air conditioner system. The sensor uses an

electrostatic volume pressure transducer to convert refrigerant pressure to voltage. The voltage signal is sent

to ECM, and ECM controls cooling fan system.

Component Function Check

INFOID:0000000001671118

1.

CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

1.

Start engine and warm it up to normal operating temperature.

2.

Turn A/C switch and blower fan switch ON.

3.

Check the voltage between ECM harness connector terminals as follows.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Go to

Diagnosis Procedure

INFOID:0000000001671119

1.

CHECK GROUND CONNECTION

1.

Turn A/C switch and blower fan switch OFF.

2.

Stop engine.

3.

Turn ignition switch OFF.

4.

Check ground connection E15. Refer to Ground Inspection in

.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace ground connection.

2.

CHECK REFRIGERANT PRESSURE SENSOR POWER SUPPLY CIRCUIT

1.

Disconnect refrigerant pressure sensor harness connector.

2.

Turn ignition switch ON.

3.

Check the voltage between refrigerant pressure sensor harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> GO TO 3.

PBIB2657E

(+)

(–)

Voltage

Connector

Terminal

Connector

Terminal

F11

41

(Refrigerant pressure sensor signal)

F11

48

1.0 - 4.0V

Refrigerant pressure sensor

Ground

Voltage

Connector

Terminal

E17

3

Ground

Approx. 5V