содержание .. 372 373 374 375 ..

Nissan Tiida C11. Manual - part 374

EC-146

< COMPONENT DIAGNOSIS >

[HR16DE (WITH EURO-OBD)]

P0122, P0123 TP SENSOR

3.

Check the voltage between electric throttle control actuator harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

3.

CHECK THROTTLE POSITION SENSOR 2 GROUND CIRCUIT FOR OPEN AND SHORT

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check the continuity between electric throttle control actuator harness connector and ECM harness con-

nector.

4.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.

CHECK THROTTLE POSITION SENSOR 2 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1.

Check the continuity between electric throttle control actuator harness connector and ECM harness con-

nector.

2.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.

CHECK THROTTLE POSITION SENSOR

EC-147, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> GO TO 6.

6.

REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

1.

Replace electric throttle control actuator.

2.

Go to

EC-147, "Special Repair Requirement"

.

>> INSPECTION END

7.

CHECK INTERMITTENT INCIDENT

GI-55, "Intermittent Incident"

>> INSPECTION END

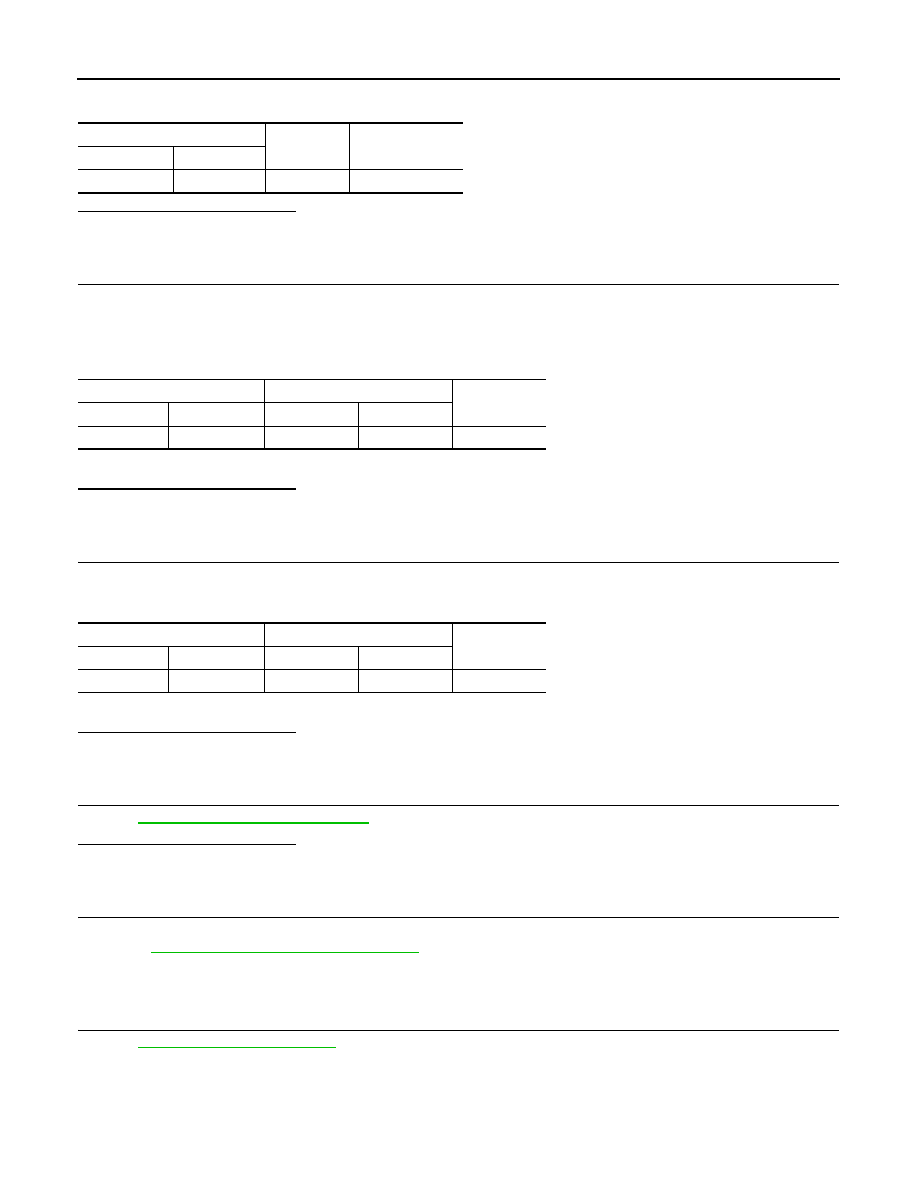

Electric throttle control actuator

Ground

Voltage

Connector

Terminal

F7

1

Ground

Approx. 5V

Electric throttle control actuator

ECM

Continuity

Connector

Terminal

Connector

Terminal

F7

4

F11

36

Existed

Electric throttle control actuator

ECM

Continuity

Connector

Terminal

Connector

Terminal

F7

3

F11

34

Existed