содержание .. 1457 1458 1459 1460 ..

Nissan Tiida C11. Manual - part 1459

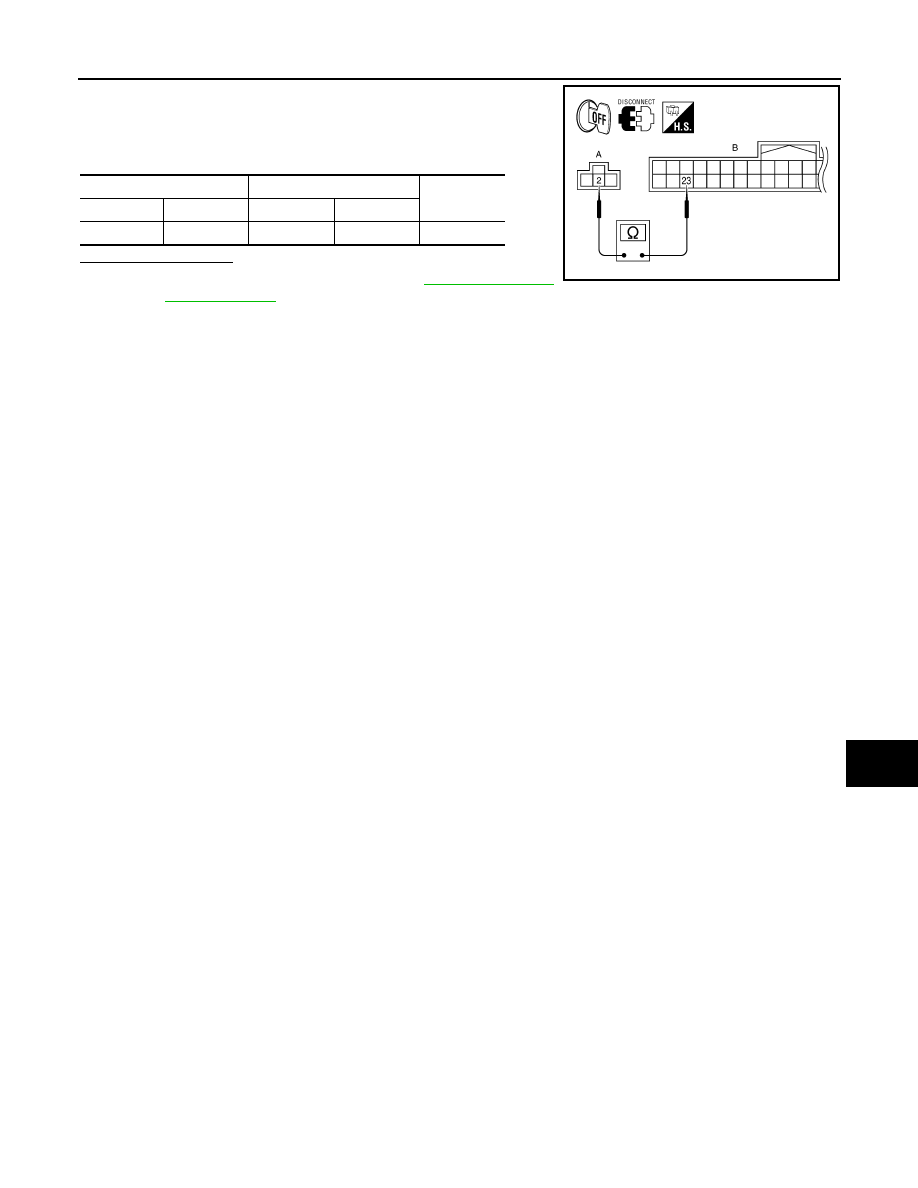

REAR WIPER AUTO STOP SIGNAL CIRCUIT

WW-31

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

M

A

B

WW

N

O

P

1.

Turn the ignition switch OFF.

2.

Disconnect BCM.

3.

Check continuity between BCM harness connector and rear

wiper motor harness connector.

Does continuity exist?

YES

>> Replace rear wiper motor. Refer to

.

NO

>> Repair or replace harness.

Rear wiper motor

BCM

Continuity

Connector

Terminal

Connector

Terminal

D404 (A)

2

M18 (B)

23

Yes

ALLIA0358ZZ