содержание .. 1398 1399 1400 1401 ..

Nissan Tiida C11. Manual - part 1400

TRANSAXLE ASSEMBLY

TM-651

< DISASSEMBLY AND ASSEMBLY >

[5MT: RS5F91R]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

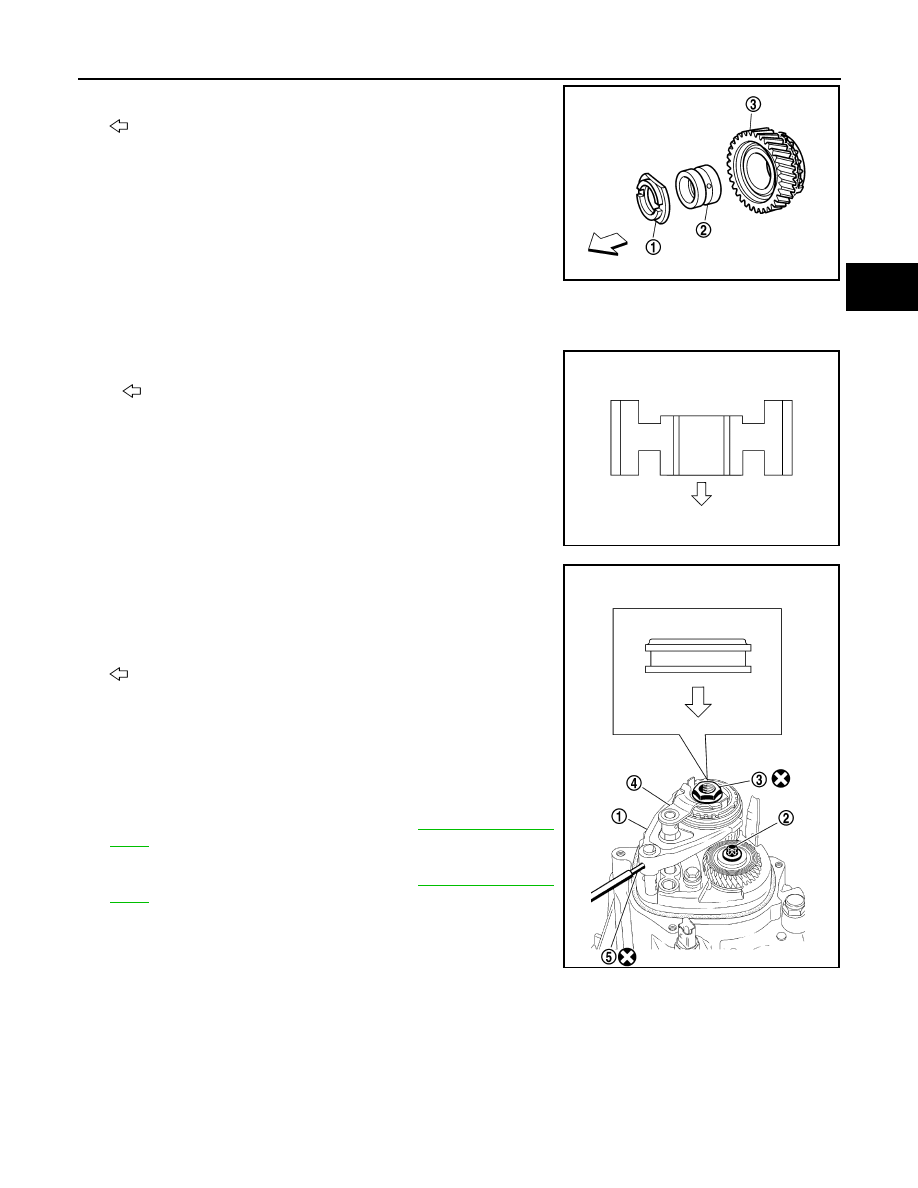

35. Install adapter plate (1), bushing (2) and 5th input gear (3) to

input shaft.

: Transaxle case side

CAUTION:

Be careful with the orientation of adapter plate.

36. Install 5th baulk ring, 5th-reverse synchronizer hub, 5th-reverse coupling sleeve, lock washer, reverse

synchronizer cone and reverse baulk ring to input shaft.

CAUTION:

• Be careful with the orientation of 5th-reverse synchro-

nizer hub.

: 5th input gear side

37. Set 5th-reverse shift fork (1) and reverse gear assembly (4) to

5th-reverse coupling sleeve, and then assemble input shaft and

5th-reverse fork rod.

CAUTION:

Be careful with the orientation of 5th-reverse coupling

sleeve.

: 5th input gear side

38. Make sure that the shift lever of control shaft assembly is shifted

to 3rd gear position. And then, push in 5th-reverse shift fork (1)

to shift it to 5th gear position.

NOTE:

When it is shifted to the 5th gear and 3rd gear at the same time,

the input shaft and mainshaft may not be rotated.

39. Install mainshaft bolt (2) to mainshaft, and then tighten main-

shaft bolt to the specified torque. Refer to

.

40. Install input shaft nut (3) to input shaft, and then tighten input

shaft nut to the specified torque. Refer to

.

41. Install retaining pin (5) to 5th-reverse shift fork using a pin

punch.

PCIB1555E

PCIB1556E

PCIB1641E