содержание .. 1397 1398 1399 1400 ..

Nissan Tiida C11. Manual - part 1399

TRANSAXLE ASSEMBLY

TM-647

< DISASSEMBLY AND ASSEMBLY >

[5MT: RS5F91R]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

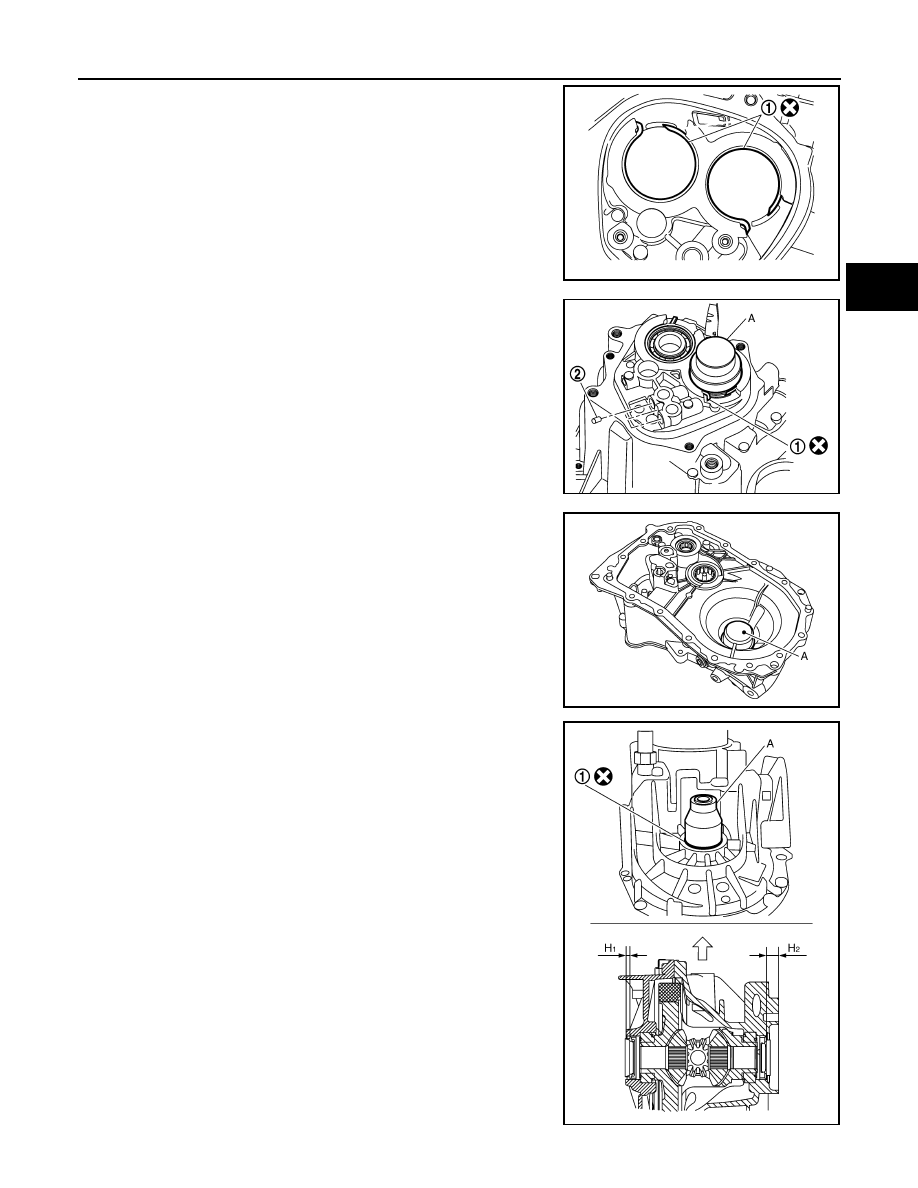

13. Install snap ring (1) to transaxle case as shown in the figure.

CAUTION:

Be careful with the orientation of snap ring.

14. Using Tool (A), with snap rings (1) stretched, press in input shaft

rear bearing and mainshaft rear bearing into transaxle case.

CAUTION:

Make sure that snap ring is installed to bearing groove

properly.

15. Install check balls (2) to transaxle case.

16. Install differential side bearing outer races until it is flush with

end face of clutch housing and transaxle case using Tool (A).

17. Install differential side oil seals (1) to clutch housing and tran-

saxle case using Tool (A).

PCIB1547E

Tool number

A: ST35300000

PCIB1548E

Tool number

A: KV32300QA

PCIB1549E

Tool number

A: ST27862000

Dimension “H

1

”

: 5.7 - 6.3 mm (0.224 - 0.248 in)

Dimension “H

2

”

: 16.4 - 17.0 mm (0.646 - 0.669 in)

PCIB1550E