содержание .. 1377 1378 1379 1380 ..

Nissan Tiida C11. Manual - part 1379

REPAIR FOR COMPONENT PARTS

TM-567

< DISASSEMBLY AND ASSEMBLY >

[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

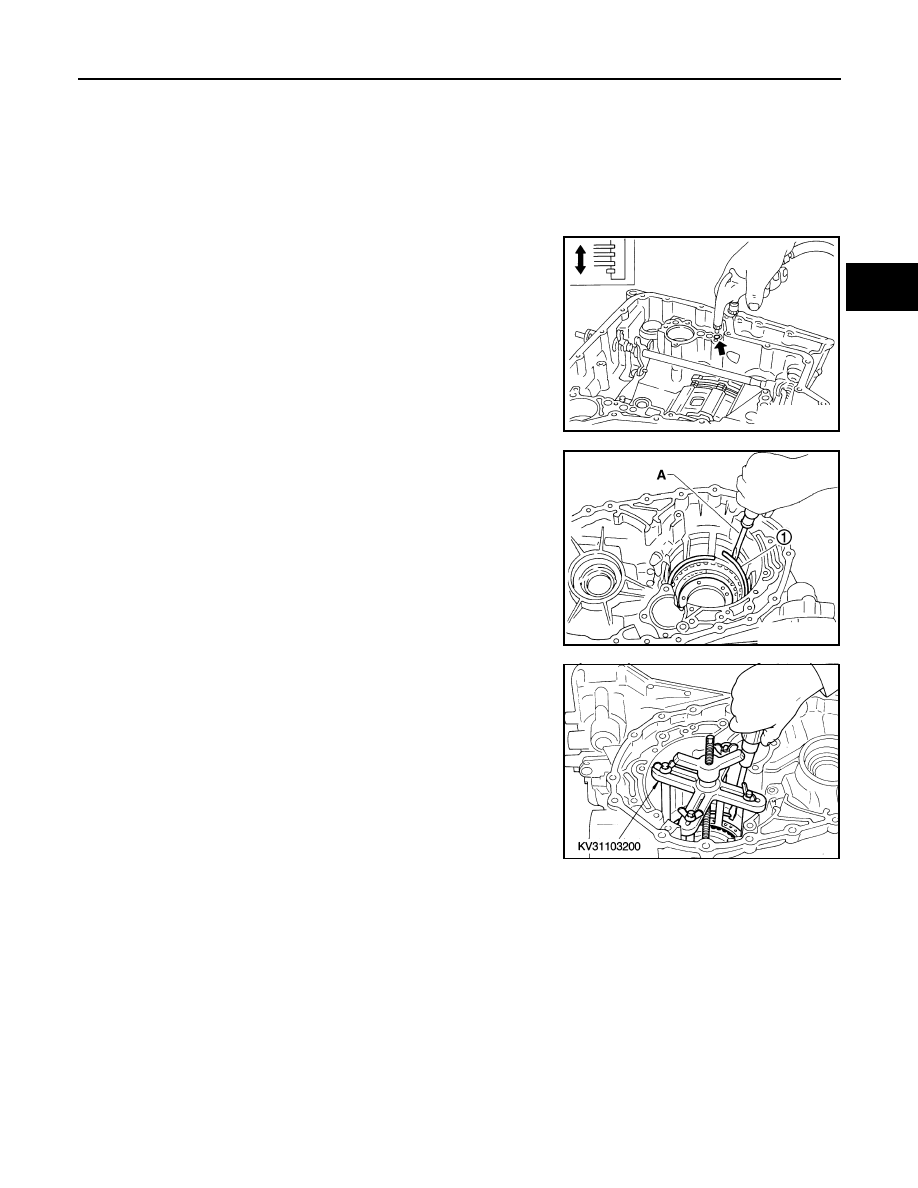

DISASSEMBLY

1.

Check operation of low & reverse brake.

a.

Apply compressed air into oil hole of transaxle case at the loca-

tion as shown.

b.

Check to see that retaining plate moves to snap ring.

c.

If retaining plate does not contact snap ring:

• D-ring might be damaged.

• Seal ring might be damaged.

2.

Remove snap ring (1) using suitable tool (A).

3.

Remove retaining plates, drive plates, driven plates, dish plates.

4.

Set Tool on spring retainer assembly, and remove snap ring

from transaxle case while compressing spring retainer assem-

bly.

CAUTION:

Set Tool directly over return springs.

5.

Remove spring retainer assembly from transaxle case.

CAUTION:

Do not remove return springs from spring retainer.

1.

Seal ring

2.

D-ring

3.

Low & reverse brake piston

4.

Spring retainer assembly

5.

Snap ring

6.

Driven plate

7.

Retaining plate

8.

Driven plate

9.

Retaining plate

10. Snap ring

11.

Drive plate

12. Dish plate

SAT230D

SCIA7039E

SAT242D