содержание .. 1353 1354 1355 1356 ..

Nissan Tiida C11. Manual - part 1355

PREPARATION

TM-471

< PREPARATION >

[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

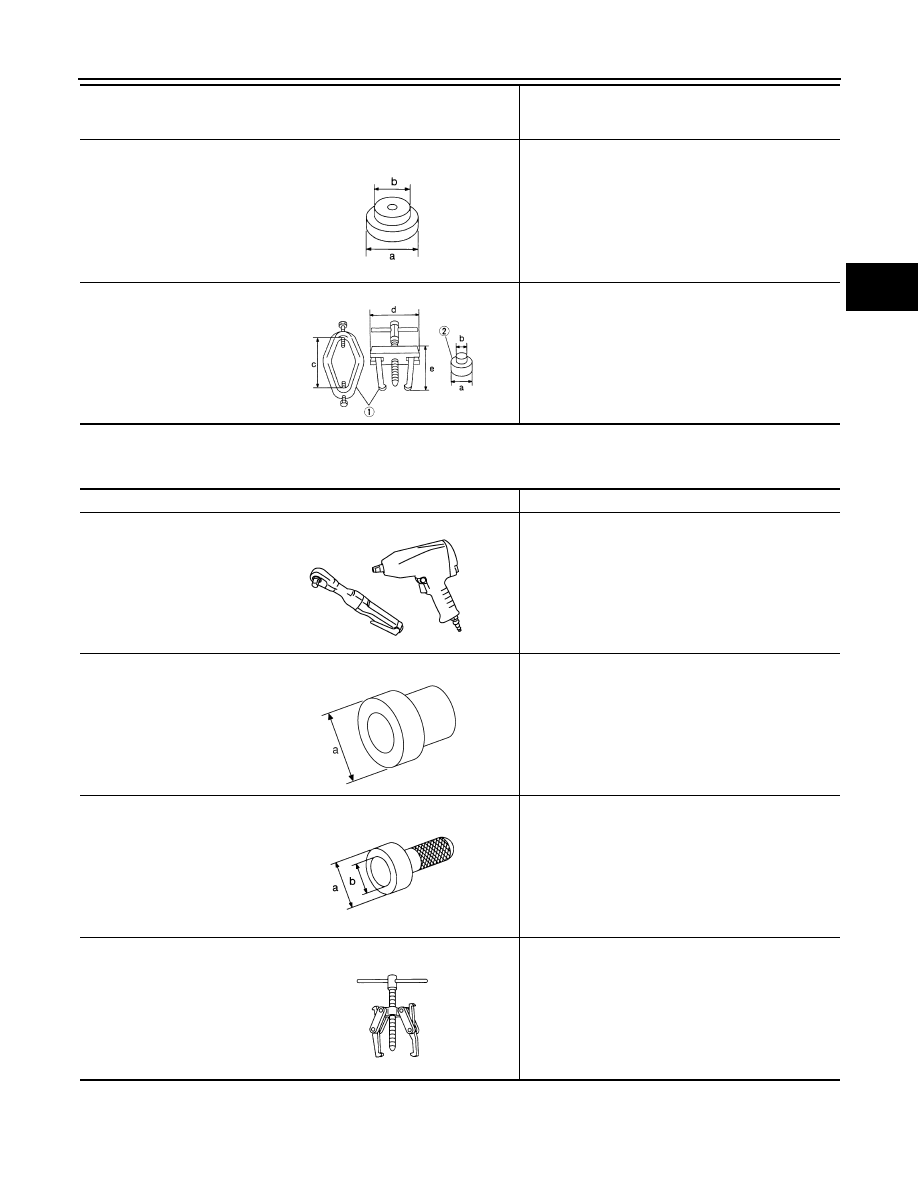

Commercial Service Tool

INFOID:0000000001731414

ST30633000

( — )

Drift

Installing differential side bearing outer races

a: 67 mm (2.48 in) dia.

b: 49 mm (1.93 in) dia.

ST3306S001

(J-22888-D)

Differential side bearing pull-

er set

1.

ST33051001

Puller

2.

ST33061000

Adapter

Removing differential side bearing inner race

a: 38 mm (1.50 in) dia.

b: 28.5 mm (1.122 in) dia.

c: 130 mm (5.12 in)

d: 135 mm (5.31 in)

e: 100 mm (3.94 in)

Tool number

(Kent-Moore No.)

Tool name

Description

NT073

AMT153

Tool name

Description

Power tool

Loosening bolts and nuts

Drift

Installing manual shaft oil seal

a: 22 mm (0.87 in) dia.

Drift

Installing RH differential side oil seal

a: 54 mm (2.13 in) dia.

b: 47 mm (1.85 in) dia.

Puller

• Removing idler gear bearing inner race

• Removing and installing band servo piston snap

ring

PBIC0190E

SCIA7105E

NT115

NT077