содержание .. 1351 1352 1353 1354 ..

Nissan Tiida C11. Manual - part 1353

SYSTEM SYMPTOM

TM-463

< SYMPTOM DIAGNOSIS >

[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

-

Shift valve A

-

Overrun clutch solenoid valve

3.

Disassemble A/T. Refer to

4.

Check the following.

-

Overrun clutch assembly. Refer to

TM-267, "Forward and Overrun Clutches"

.

-

Low & reverse brake assembly. Refer to

.

OK or NG

OK

>> GO TO 10.

NG

>> Repair or replace damaged parts.

10.

CHECK SYMPTOM

TM-186, "Cruise Test - Part 3"

OK or NG

OK

>> INSPECTION END

NG

>> GO TO 11.

11.

CHECK TCM

1.

Check TCM input/output signals. Refer to

TM-22, "Input/Output Signal of TCM"

2.

If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK

>> INSPECTION END

NG

>> Repair or replace damaged parts.

TCM Self-Diagnosis Does Not Activate

INFOID:0000000001714365

SYMPTOM:

OD OFF indicator lamp does not come on in TCM self-diagnostic procedure even if the lamp circuit is

good.

DESCRIPTION

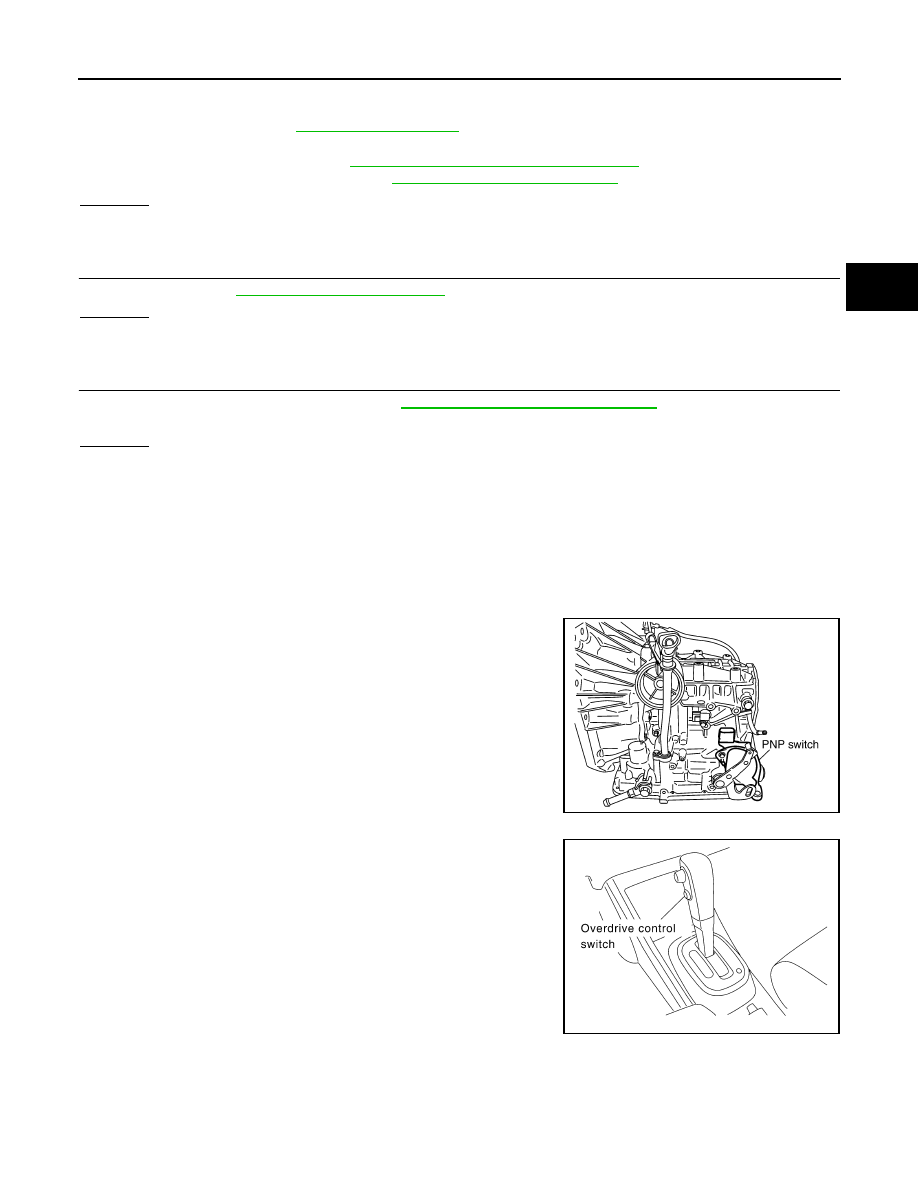

• PNP switch

PNP switch assembly includes a transaxle position switch. The

transaxle position switch detects the selector lever position and

sends a signal to the TCM.

• Overdrive control switch

Overdrive control switch detects the switch position (ON or OFF)

and sends a signal to the TCM.

SCIA7141E

SCIA7142E