содержание .. 1260 1261 1262 1263 ..

Nissan Tiida C11. Manual - part 1262

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM

POWER SOURCE)

TM-99

< COMPONENT DIAGNOSIS >

[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND

TCM POWER SOURCE)

Description

INFOID:0000000001694393

The A/T fluid temperature sensor detects the A/T fluid temperature and sends a signal to the TCM.

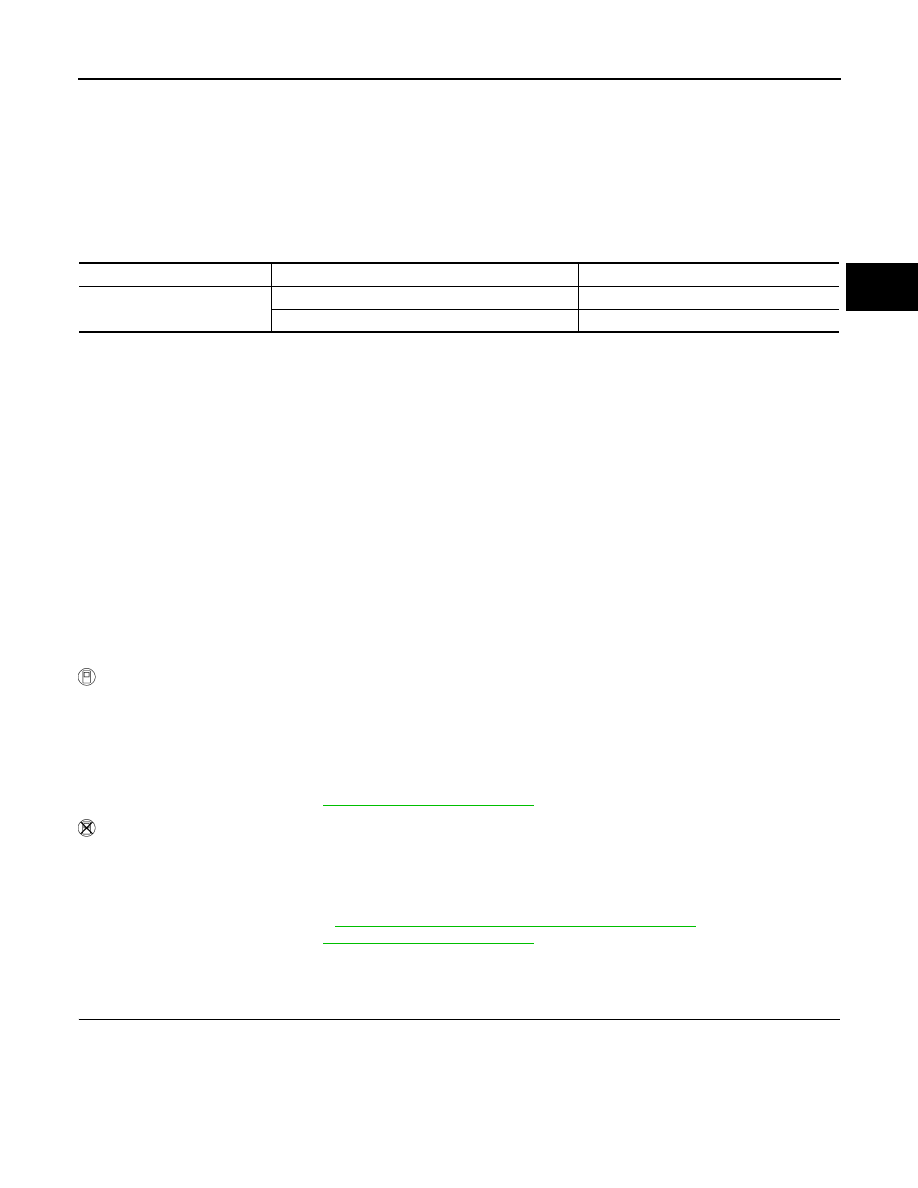

CONSULT-III Reference Value in Data Monitor Mode

INFOID:0000000001694394

Remarks: Specification data are reference values.

On Board Diagnosis Logic

INFOID:0000000001694395

• This is not an OBD self-diagnostic item.

• Diagnostic trouble code “BATT/FLUID TEMP SEN” with CONSULT-III or 8th judgement flicker without CON-

SULT-III is detected when TCM receives an excessively low or high voltage from the sensor.

Possible Cause

INFOID:0000000001694396

• Harness or connector

(The sensor circuit is open or shorted.)

• A/T fluid temperature sensor

DTC Confirmation Procedure

INFOID:0000000001694397

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1.

Start engine.

2.

Select “DATA MONITOR” mode for “A/T” with CONSULT-III.

3.

Touch “START”.

4.

Drive vehicle under the following conditions.

SLCT LVR POSI: “D” position

VEHICLE SPEED: Higher than 20 km/h (12 MPH)

5.

If the check result is NG, go to

WITHOUT CONSULT-III

1.

Start engine.

2.

Drive vehicle under the following conditions.

Selector lever position: D position

Vehicle speed: higher than 20 km/h (12 MPH)

3.

Perform self-diagnosis. Refer to

TM-38, "Diagnosis Procedure without CONSULT-III"

4.

If the check result is NG, go to

Diagnosis Procedure

INFOID:0000000001694399

1.

CHECK TCM POWER SOURCE

1.

Turn ignition switch ON. (Do not start engine.)

Item name

Condition

Display value

FLUID TEMP SE

When A/T fluid temperature is 20

°

C (68

°

F).

1.5V

When A/T fluid temperature is 80

°

C (176

°

F).

0.5V