содержание .. 108 109 110 111 ..

Nissan Tiida C11. Manual - part 110

CHG-18

< PREPARATION >

[MR18DE]

PREPARATION

PREPARATION

PREPARATION

Special Service Tools

INFOID:0000000001691351

Tool number

Tool name

Description

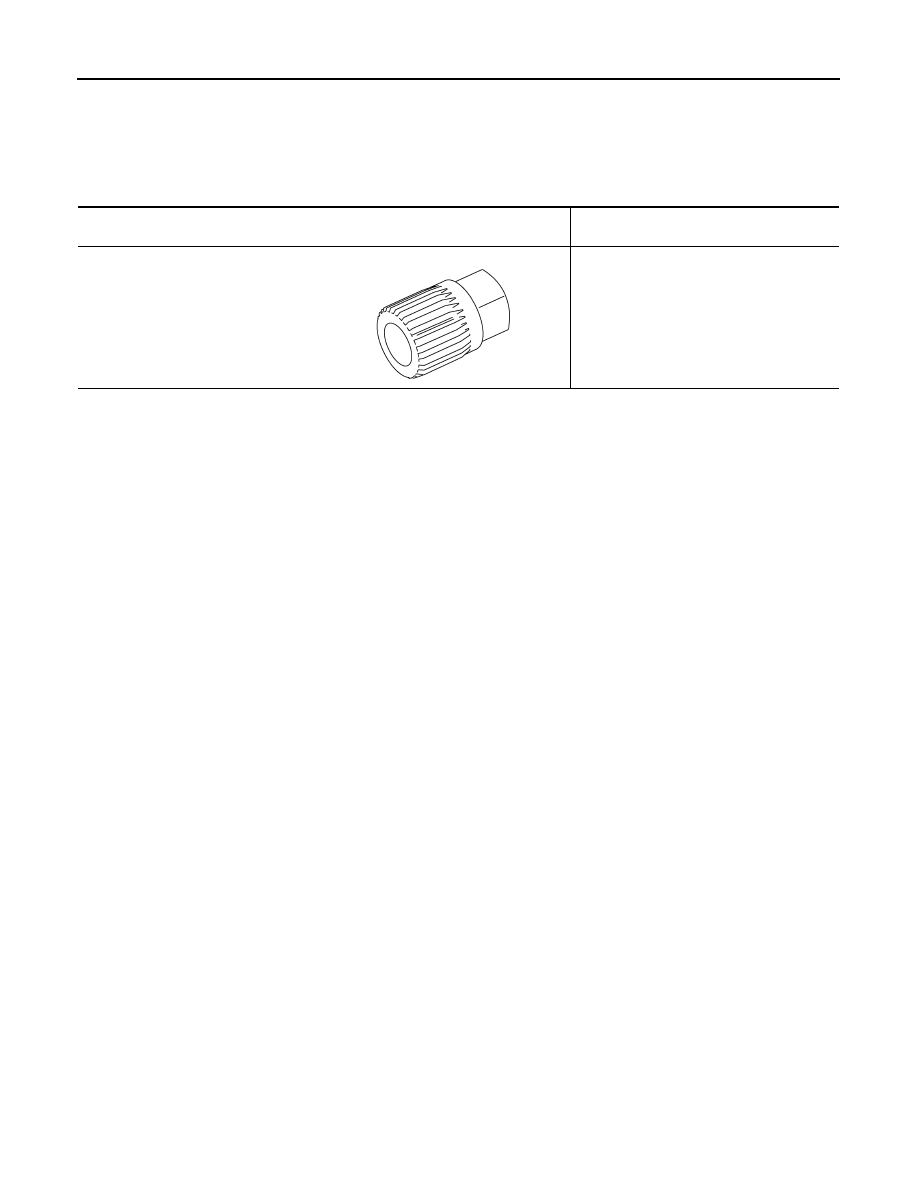

KV10118200 (included in the adapter

kit: Mot. 1732)

Alternator pulley adapter

Removing and installing alternator pulley

PKIA1241E