содержание .. 1070 1071 1072 1073 ..

Nissan Tiida C11. Manual - part 1072

ENGINE MAINTENANCE (K9K)

MA-45

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

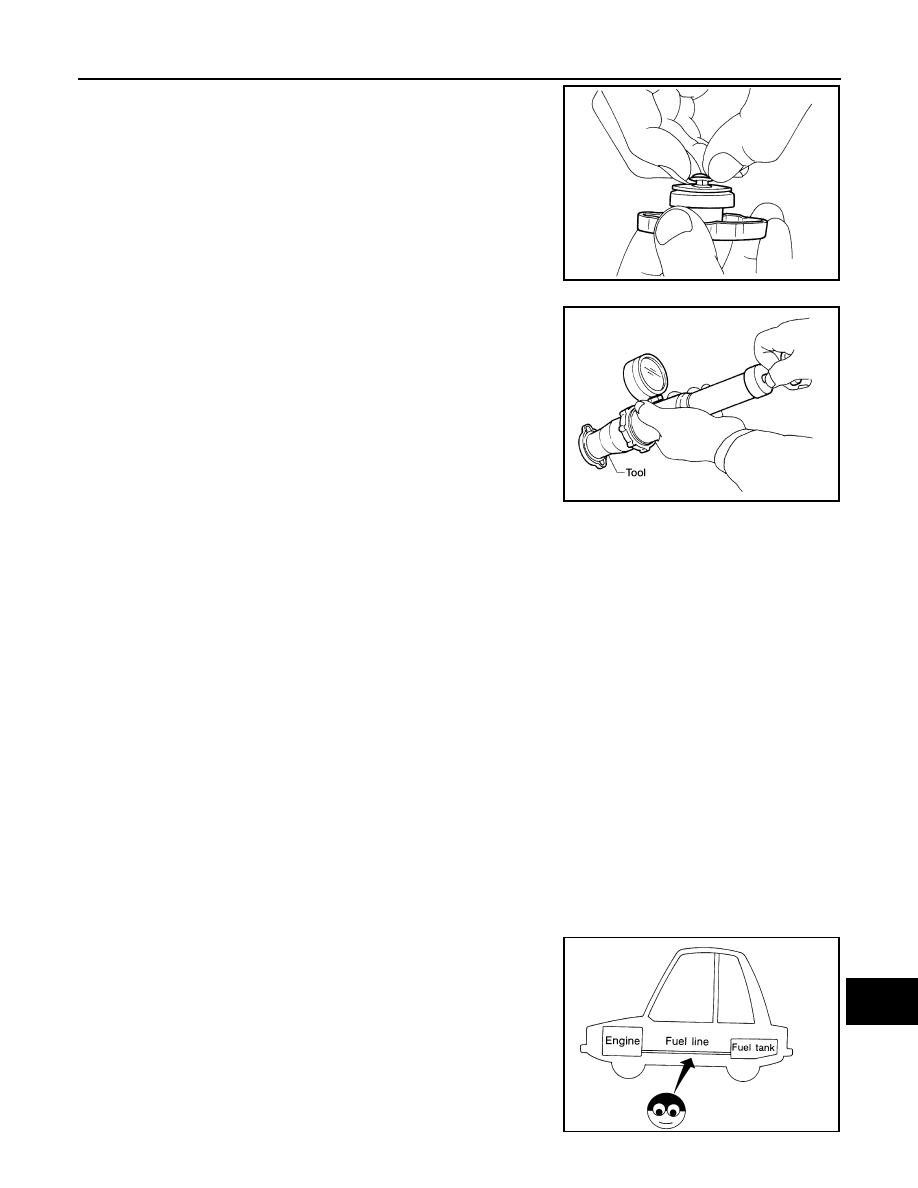

• Pull negative-pressure valve to open it, and make sure that it is

completely closed when released.

- Make sure that there is no dirt or damage on the valve seat of radi-

ator cap negative-pressure valve.

- Make sure that the valve operates properly in the opening and

closing conditions.

• Check radiator cap relief pressure using suitable tool.

- When connecting the radiator cap to the tester, apply water or

coolant to the cap seal surface.

- Replace the radiator cap if there is an abnormality in the negative-

pressure valve, or if the open-valve pressure is outside of the stan-

dard values.

• Replace radiator cap if there it does not comply to specifications to the above three checks.

CAUTION:

When installing radiator cap, thoroughly wipe out the radiator filler neck to remove any waxy residue

or foreign material.

RADIATOR : Checking Radiator

INFOID:0000000001730885

Check radiator for mud or clogging. If necessary, clean radiator as follows.

• Be careful not to bend or damage radiator fins.

• When radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator shroud

and horns. Then tape harness and connectors to prevent water from entering.

1.

Apply water by hose to the back side of the radiator core vertically downward.

2.

Apply water again to all radiator core surface once per minute.

3.

Stop washing if any stains no longer flow out from radiator.

4.

Blow air into the back side of radiator core vertically downward.

• Use compressed air lower than 490 kPa (4.9 bar, 5 kg/cm

2

, 71 psi) and keep distance more than 30 cm

(11.8 in).

5.

Blow air again into all the radiator core surfaces once per minute until no water sprays out.

FUEL LINES

FUEL LINES : Inspection

INFOID:0000000001277645

Inspect fuel lines, filler cap and tank for improper attachment, leaks,

cracks, damage, loose connections, chafing or deterioration.

If necessary, repair or replace damaged parts.

SMA967B

Standard: 78 – 98 kPa (0.78 - 0.98 bar, 0.8 – 1.0 kg/cm

2

, 11

– 14 psi)

Limit: 59 kPa (0.59 bar, 0.6 kg/cm

2

, 9 psi)

WBIA0570E

SMA803A